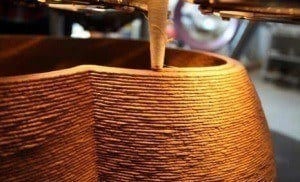

3D printing technology uses the latest “ultra-cool” movement. Ever since we heard about 3D printing, we remember the small 3D printers. It began to imagine how the world would look if 3D printing became such a common procedure as paper printing.

There’s a world full of home-made toys, dishes, utensils, and lots more. What if 3D printing offer excellent solution with solve the issue of shelter around the globe. What if there could provide a feasible solution to a 3D print houses?

The idea of ContourCrafting comes when CEO offer a very insightful TED talk. The Professor Behrokh Khoshnevis, from the University of Southern California, is the man that have built this awesome concept. In simple words, he wants to make a 3D printer within 20 hours. The vast 3D home builder creates the entire building, from the foundation, floor, ceiling, and plumbing. At the beginning, we thought it could build the main block of the building.

The 3D printer from ContourCrafting is far more crafted than this. It would build houses in such a way that you’d only require to put the windows and the doors in the cutouts. The vast construction robot left this. Maybe one wouldn’t like living in such a home built by a gigantic 3D printer.

But almost 1 billion people don’t have stable shelter. Therefore, do you think, they’ll think twice before moving in? It can be an immediate and most urgent use for 3D printed home. But I can imagine that the rest of us, or those with money, can print their own house in less than one day.

Inspiring 3D printers that will reshape the construction

Right from the start, we were confused that how to build big buildings with hundreds of flats? How are they going to achieve that? But the CountourCrafting guys created the model of a 3D printer. It’s building that capable of designing everything. And something that surprised was some 3D printer capable of climbing and finishing the printing to a next level.

The technology seems very impressive and can build more advanced buildings using advanced designs. We use a perfectly calculated geometry using the strong material. The house-building with 3D printers can replicate historic or progressive buildings. How cool, isn’t it.

It does sounds excellent on paper, but what’s the reality…

Behrokh Khosnevis says, this technology is far more secure and safe than current construction methods. He said that the 10,000 workers die each year in the USA and 400,000 get injured during construction. But with 3D construction printers, we could eliminate and decrease lot of the time that require to build a house. There are drawbacks that we can’t ignore. Let’s discuss them.

3D printing house to build in 20 hours!

Imagine how many jobs get lost if the technology were become mainstreams. We have a team that supports a civilization and rely on the technology. Thus, with being more automated, it manually runs using this technology. Few houses are built using this concept, but it will not gain mass appeal as the government requires to keep the population employed. But again, the same thing happened when the Industrial Revolution began.

The people were afraid that they would lose jobs as technological devices were there to take tasks from humans. But when we look behind, we see that humanity has found a place for everybody. It can be an issue for the moment, but imagine that by 2050 or beyond 3D printed homes not be just a “cool concept”. Instead, it could be something ordinary. The appearance of the Web won’t kill jobs, it could change the world. The 3D printing won’t kill construction, it can reshape in near future.

What a brave new world it could be?

The technology is excited that it wants to be a part of it. One can see 3D printed houses around and people living in them. One can see huge 3D printers outside the towns. There could be building from the ground homes for everybody. Let’s imagine using this technology, one can build houses on other planets as well. Get connected, if you’re looking for a leading Australian design and drafting service company, here we are to help you solve your problem.

Is 3D printed house strong?

The strength of a 3D-printed house depends on various factors such as the materials used, the printing technology, the design, and the structural integrity. Generally, 3D-printed houses can be quite strong and durable if they are designed and constructed properly. Many construction companies are exploring the use of high-strength materials like concrete, composite materials, and even advanced polymers for 3D printing homes. Additionally, the ability to create intricate geometries and customized designs through 3D printing can sometimes result in structures that are more robust than traditional construction methods. However, it’s essential to ensure that the printing process is carefully controlled and monitored to maintain quality and structural integrity. Overall, with the right materials and techniques, 3D-printed houses can indeed be strong and reliable.

What are the disadvantages of 3D printed houses?

While 3D printed houses offer numerous advantages, they also come with some disadvantages:

Limited Materials: Currently, most 3D printed houses are constructed using materials like concrete or synthetic materials, which may not be as environmentally friendly as traditional building materials like wood or brick.

Limited Design Flexibility: While 3D printing allows for innovative designs, it can also limit the architectural freedom compared to traditional construction methods. Intricate designs or non-standard shapes may be challenging to achieve.

Quality Control Challenges: Ensuring the structural integrity and quality of a 3D printed house can be challenging, especially if the printing process encounters errors or inconsistencies. Quality control measures need to be robust to guarantee the safety and longevity of the structure.

Dependency on Technology: 3D printing technology is still evolving, and reliance on it for construction means being dependent on the advancements and reliability of this technology. Technical glitches or failures in the printing process can lead to delays and added costs.

Regulatory Hurdles: Building codes and regulations often lag behind technological advancements. Incorporating 3D printed houses into existing regulatory frameworks may require significant adaptation and approval processes, which can be time-consuming and cumbersome.

Scalability Challenges: While 3D printing has the potential to revolutionize construction, scaling up the technology for mass adoption on a large scale presents logistical and infrastructure challenges. The current scale of 3D printing is limited, and widespread adoption would require significant investment and infrastructure development.

Skilled Labor Requirement: Despite automation in the printing process, skilled labor is still required for setup, maintenance, and finishing work. Ensuring an adequate workforce with the necessary skills to operate and maintain 3D printing equipment can be a challenge.

Perception and Trust: Acceptance of 3D printed houses among consumers, builders, and regulators may be hindered by skepticism or distrust regarding the durability, safety, and longevity of these structures. Building confidence in the technology and its capabilities is crucial for widespread adoption.

Cost Considerations: While 3D printing has the potential to reduce construction costs in the long run, initial setup costs, including investment in printing equipment and infrastructure, may be substantial. Additionally, the cost-effectiveness of 3D printing may vary depending on factors such as project size, location, and material availability.