Choosing an appropriate plant design management system service is tricky. We evolve and incorporate the latest technology by designing, planning, modifying, maintaining, and installing various plant systems, equipment, etc. Our team of PDMS services the best robust industrial plant design that caters to your current and future needs. We use excellent mechanical design, structural, piping and instrumental designs.

AstCAD is one of the Australian Design & Drafting Service that offers an efficient plant design management team that comprises experienced engineers, draftsmen, senior designers, and managers to provide cost-effective solutions within the required turnaround time. We are a stepping stone towards increased productivity, fewer bottlenecks, the ability to manufacture different products concurrently, and overall business expansion. We offer the most efficient software that provides a strong suit for creating, analyzing and documenting real-life plants in its 3D representation of the logically interconnected system.

OUR SERVICE PORTFOLIO – PLANT

DESIGN MANAGEMENT SYSTEM – DESIGN & DRAFTING

We offer the best design and drafting services for various industry verticals like Piping, Civil & Structural, Electrical & Instrumentation, and Industrial Equipment. Our offering for an efficient plant design management system covers the following:

PRE-BID PROPOSAL ENGINEERING

We are domain experts in providing practical pre-bid engineering proposals. We assist numerous global clients and contractors during the pre-bid process by performing the following essential activities, though not limited to:

- Design initial conceptual designs in accordance to bid parameters

- Provide engineering estimates

- Estimate the bill of quantities

- Collect necessary data directly from the site if required

BID EVALUATION ASSISTANCE

Over the years, we have used a wide range of services by offering a technical support team. We provide exemplary bid evaluation assistance to our clients by providing an in-depth technical analysis of the bids received. Our analysis considers several factors to collaborate the legitimacy of the bid, such as the price of materials, products, personnel skills and qualification, prior projects handled by the bidder etc. We evaluate the bids carefully, help our clients save time and money, and focus on other essential project-related work.

DETAILED ENGINEERING

As part of the detailed engineering, piping and plant construction project, our client performs various studies to extract the necessary information from basic engineering drawings and project calculations. Our complex engineering services consist of the following –

- MTO (BOM)

- Piping GA Drawings & Piping Routing

- Piping Isometric & Support Drawings

- Prepare 2-D & 3-D plant model

- Build 3D plant model from available 2D drawings

- Put together the equipment list for purchase

- Designing cause and effect diagrams

- Prepare piping and instrument diagrams, including all stress calculations and isometrics.

- Formulate necessary start-up procedures and design all civil and electrical diagrams.

DESIGN AND DRAFTING SERVICES

We have an enviable track record in providing quality designing and drafting services to our global clients for efficient plant engineering. Our project managers use the best design process that consists of the following –

- Designing detailed drawings based on source data

- Validating all drawings

- Creating 3D parametric CAD designs

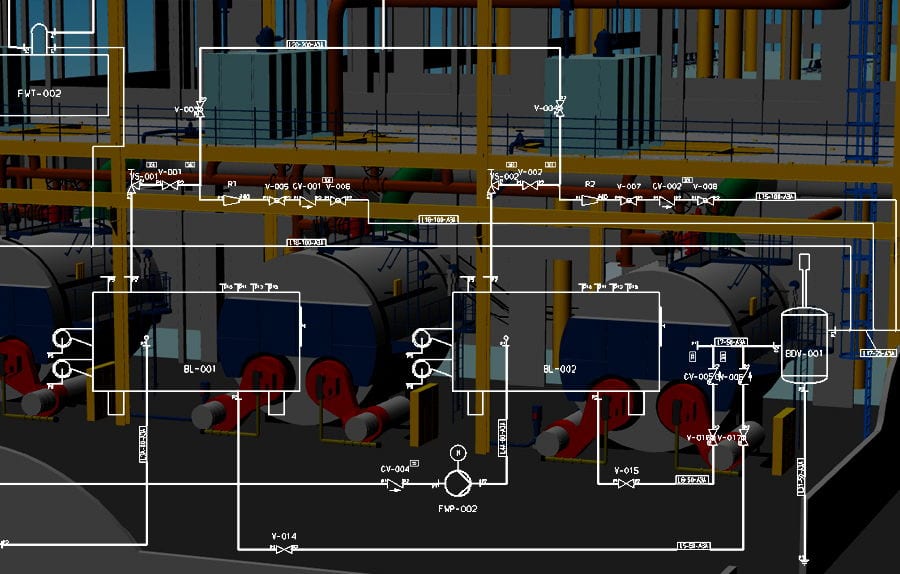

3D MODELING AND DESIGN

Our plant 3D modelling and design services enable faster and accurate plant modelling. We have a 3D modelling and design team with in-depth knowledge of 3D design software and engineers who ensure smooth workflow integration. We reduce turnaround times for the related project. Our team of engineers and plant designers are well-versed in various 3D design software and provide consistent workflow integration throughout the project enterprise. Our offering for 3D modelling and design includes the following:

- Equipment Modelling

- Piping Modelling

- Pipe Rack Modelling

- Support Modelling

- 3D Models in PDMS

- General Arrangement

- Safety Equipment Arrangement

- Structural Elevation

- Specifications and Datasheets

AS-BUILT DOCUMENTATION

Our As-built documentation and engineering service ensures comprehensive and accurate final documentation for an as-built plant. Our experienced team of engineers is knowledgeable in various commercial document management systems such as PDS, ProArc, etc. It conducts site surveys that involve taking necessary measurements, documenting markups, updating 3D models etc., based upon the client request.

PIPING DESIGN

We offer state-of-the-art piping design and engineering services to ensure optimum quantities, easy operability, constructability, and safety of industrial plants. Our offerings for piping design and engineering include:

- Preparation of piping specifications

- Plot Plan development

- Basic equipment layout

- Equipment layout and section

- Piping layout & sections

- Pipe support layout & support details

- Isometric drawings

- Bill Of Material

- nozzle orientation drawing

- Valve specification

- Erection of Piping

ON-SITE ENGINEERING CONSULTATION

Our on-site plant engineering consultation service complements our clients’ in-house development teams by providing consultation on varied aspects of the plant engineering lifecycle.

- Consultation before a permit is awarded.

- Consultation for all contractual phases

- Due diligence

- Project management and relocation

Plant Design Management Systems for industries

Plant Design Management Systems (PDMS) are specialized software tools used in various industries, including oil and gas, petrochemical, chemical, power, and other process industries. These systems aid in designing, constructing, and maintaining industrial plants, facilitating efficient project management and collaboration among different engineering disciplines.

PDMS services for industries typically include:

- Software Implementation: Consulting and assisting with installing, setting up, and configuring PDMS software within a company’s existing infrastructure.

- Customization: Tailoring the PDMS software to meet the specific needs and workflows of a particular industry or company.

- Training: Providing training programs for engineers, designers, and project managers to effectively use PDMS software for their design and project management tasks.

- Project Execution: Supporting the entire project lifecycle, from conceptual design to detailed engineering and construction, using PDMS software to optimize plant design and layout.

- 3D Modeling: Creating detailed 3D models of the plant equipment, piping, structures, and instrumentation using PDMS software.

- Clash Detection and Interference Checking: Using PDMS to identify clashes or interferences between different plant components during the design phase prevents costly issues during construction.

- Materials Management: Integrating PDMS with material management systems to ensure accurate materials, inventory, and procurement tracking throughout the project.

- Data Management: Implementing data management strategies and workflows to maintain data integrity, version control, and information sharing across project teams.

- As-Built Documentation: Creating accurate as-built documentation based on the finalized plant design, facilitating efficient plant operation and maintenance.

- Integration with Other Systems: Integrating PDMS with other engineering software tools and systems, such as Computer-Aided Design (CAD) software, Enterprise Resource Planning (ERP) systems, and Project Management tools.

- Maintenance and Support: Providing ongoing maintenance, technical support, and updates to ensure the PDMS system continues to function effectively.

The services offered may vary depending on the specific requirements of each industry and project. PDMS systems play a crucial role in improving efficiency, reducing costs, and enhancing collaboration in complex plant design and construction projects.