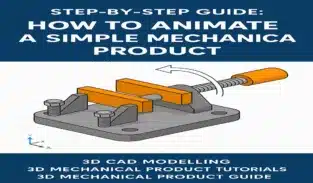

Sheet metal design is a vital skill in mechanical and industrial engineering, enabling the creation of durable and functional parts used in products ranging from electronics to automotive and aerospace systems. For CAD beginners, understanding how to approach sheet metal design for fabrication can make the difference between a concept that works in theory and one that performs reliably in the real world.

In this tutorial, we’ll walk you through the key steps of designing for sheet metal fabrication using CAD tools. We’ll also provide helpful tips to avoid common pitfalls and ensure your designs are both manufacturable and cost-effective.

What Is Sheet Metal Design?

Sheet metal design involves creating flat 2D or 3D models that can be fabricated into parts by processes like bending, cutting, punching, and welding. Unlike standard 3D modeling, sheet metal design requires you to account for factors like bend allowances, material behavior, and tool constraints.

CAD software like SolidWorks, AutoCAD, and Fusion 360 often includes dedicated sheet metal modules, making it easier to unfold designs and prepare them for manufacturing.

Step-by-Step Beginner’s Guide to Sheet Metal Design

1. Choose the Right Material

Before you start designing, understand the properties of your sheet metal material. Common materials include:

- Mild steel – affordable and easy to form

- Stainless steel – corrosion-resistant but harder to bend

- Aluminum – lightweight and corrosion-resistant

- Copper and brass – used in decorative and electrical applications

Each material has different thicknesses, minimum bend radii, and strength characteristics, all of which affect your design.

2. Start with a Base Feature

In CAD, a base flange/tab is typically the starting point. This flat profile acts as the foundation for your design.

- Begin with a 2D sketch on the top plane.

- Extrude it to the desired thickness of your sheet.

- Use the Sheet Metal toolset to convert it into a sheet metal part (if not already using a dedicated sheet metal template).

3. Add Bends and Flanges

Using the CAD software’s bend or flange tools, add the necessary folds and edges to your design.

Key bend considerations:

- Maintain a minimum bend radius (typically equal to the sheet thickness).

- Avoid bending too close to holes or edges, as this may lead to cracking or deformation.

- Use uniform bend directions wherever possible to simplify the manufacturing process.

4. Consider Bend Allowance and K-Factor

When metal bends, it stretches and compresses. This needs to be accounted for in your flat pattern layout using bend allowance and K-factor.

- Bend Allowance: The arc length of the bend, which must be added to the flat length.

- K-Factor: A ratio that defines how material stretches during bending (commonly between 0.3 to 0.5 for most materials).

Modern CAD software can calculate this automatically when you input the material and bend radius.

5. Create Cutouts and Holes with Proper Spacing

Holes, slots, and cutouts are common in sheet metal parts, but their placement is crucial.

- Keep holes at least 2x the material thickness away from bends.

- Ensure minimum hole diameter is not smaller than the thickness of the material to avoid deformation.

- Use standard hole sizes wherever possible for tooling efficiency.

6. Unfold and Flatten the Design

Once your model is complete, use your CAD software to generate the flat pattern.

This allows you to:

- Export DXF files for laser cutting or CNC punching.

- Validate the manufacturability of your part.

- Check for interference or overlap in bends or flanges.

7. Add Reliefs to Prevent Tearing

When bending corners or edges, bend reliefs help avoid tearing or warping.

- Use rectangular or obround reliefs where necessary.

- Most CAD tools offer preset relief options you can apply automatically.

8. Review for Manufacturability

Before finalizing your design:

- Review for minimum bend radii.

- Ensure standard tooling can produce the part.

- Minimize the number of bends and tooling operations where possible.

Sending your design to a fabricator for feedback can help optimize it further.

Best CAD Tools for Sheet Metal Design

- SolidWorks Sheet Metal Module – Highly intuitive and widely used in industry.

- AutoCAD Mechanical – Great for 2D layouts and DXF file exports.

- Fusion 360 – Good for beginners and hobbyists, with built-in flat pattern support.

- Onshape – Cloud-based and great for collaboration.

Conclusion

Mastering sheet metal design is a valuable skill for any aspiring CAD designer. By understanding the basics—material selection, bending rules, allowances, and proper CAD workflow—you can create parts that are not only functional but also easy and cost-effective to manufacture.

As you grow more confident with your CAD software, you’ll be able to create more complex designs, improve production efficiency, and reduce waste in your fabrication projects.

What is the minimum bend radius in sheet metal design?

The minimum bend radius typically equals the material thickness but may vary based on material type. Always check manufacturer guidelines.

Why is bend allowance important in sheet metal design?

Bend allowance accounts for the stretch that occurs when bending. Without it, flat patterns won’t be accurate.

How do I prevent tearing near bends?

Use bend reliefs and avoid placing holes or slots too close to bends.

Can I use regular 3D CAD tools for sheet metal design?

Yes, but it’s better to use tools with dedicated sheet metal modules to automate flattening and calculations.

What file format should I export for fabrication?

Most fabricators prefer DXF files for flat patterns and 2D cutting.