The architect developed a stunning 3D printing models

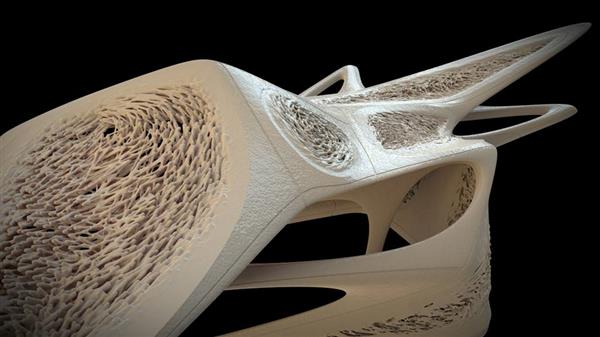

We have seen examples that prove that CAD design would be combined with 3D printing and produce fantastic artworks. It’s like a Turkish architect named Daghan Cam, and it depends on the software creation of art projects. It helps in computer simulation technology, primarily based on advanced algorithms. The robot creates an image processing training with a highly artistic 3D printed structure.

Architect developed a stunning 3D printing models

Daghan Cam is a pretty different architect. He founded his namesake architectural design company is based in London and Istanbul. At the University of London Bartlett School of Architecture faculty. Before this, he worked with famous architect Zaha Hadid, who worked and taught worldwide. In 2012, he receive an honorary Master of Architecture Degree with Distinction. Overall, Daghan Cam is a computational design, mechanical engineering and large-scale 3D printing specialist areas.

From his architectural design, one can read keywords. One can see from the chart of the design model. It’s the essence design for futuristic and the Sydney Opera House. It is combined with the Milan Design Week to offer wide attention. Cam developed a GPU computing technology and algorithms combined to create fantastic and impressive models. The so-called GPU computing provides an app that calculates the part by heavy-handed GPU processing. It offers the remaining program in the CPU that is on the method. The method achieves unprecedented application performance.

The 3D printing effects comes with its unique programming through image processing robots. The team spent several years using a CUDA parallel programming model using NVIDIA GPU coded to develop these robots.

Specifically, Cam design week offers an architectural model that use Quadro K6000 graphics and Tesla K40 GPU accelerators to support low accomplished superior computing power. The devices make the algorithm more sufficient to support such a gorgeous 3D shape creation. The Boston Corporation and Belgium 3D print vendors Materialize use the world’s largest stereolithography 3D printer. It prints the overall model time. You might ask that it’s a modern aesthetic that has become an actual building? As a senior architect, the answer is that it uses the least number of materials to reduce construction costs and add structural integrity.

After the great success of Milan, the Bartlett School of Architecture supports the application of technology to its wider range of projects. The large-scale 3D print manufacturing technology and robotics optimize deep learning algorithms for real-time image processing and robotics.

You need to develop a robot construction technology to effectively build these structures with its own decisions. Some of them still rely on NVIDIA cuDNN and its deep neural network library. Industrial manufacturing robots are mainly used for training.

Finally, Cam explains: “It’s just a prototype or artwork that can be used in the construction industry. It aims to explore the creative fidelity conversion process from intention-to information processing.” It is used as 3D printing innovation to use in the construction industry.

What is a 3D printing model?

A 3D printing model, also known as a digital model or a 3D model, is a virtual representation of a physical object created using computer-aided design (CAD) software or acquired through 3D scanning techniques. These models are typically stored in digital file formats such as STL (stereolithography) or OBJ (object) files.

The 3D printing model contains all the necessary geometric information required to produce the object layer by layer using a 3D printer. This information includes the shape, dimensions, and often intricate details of the object.

Once a 3D printing model is created or obtained, it can be sent to a 3D printer, which interprets the digital information and constructs the physical object by depositing or solidifying material layer by layer according to the specifications outlined in the model.

How do I print a 3D model?

Printing a 3D model involves several steps, but here’s a basic guide to get you started:

Choose or Create a 3D Model: You can either design your own 3D model using CAD software like Tinkercad, Fusion 360, or Blender, or you can download a pre-made model from various online repositories like Thingiverse, MyMiniFactory, or GrabCAD.

Prepare the Model: If necessary, use slicing software to prepare the model for printing. Slicing software takes the 3D model and generates the toolpath instructions (G-code) that the 3D printer needs to create the object layer by layer. Popular slicing software includes Cura, Slic3r, and PrusaSlicer.

Load the Model into Slicing Software: Import your 3D model into the slicing software. Adjust settings such as layer height, infill density, and print speed according to your preferences and the capabilities of your printer.

Slice the Model: Use the slicing software to generate the G-code instructions for your specific 3D printer. This process divides the model into layers and calculates the paths the printer’s nozzle or laser will follow to create each layer.

Transfer G-code to Printer: Save the sliced G-code file to an SD card or connect your computer directly to the 3D printer if it supports USB connectivity. Transfer the G-code file to the printer.

Prepare the Printer: Ensure that your 3D printer is properly calibrated, and the print bed is clean and level. Load the filament (or resin, in the case of resin printers) into the printer according to the manufacturer’s instructions.

Start Printing: Use the printer’s interface to select the G-code file you transferred earlier. Start the printing process, and the printer will begin creating your object layer by layer.

Monitor the Print: Keep an eye on the print throughout the process to ensure everything is proceeding smoothly. Address any issues that arise, such as filament jams or adhesion problems.

Remove the Print: Once the print is complete, carefully remove it from the print bed. Depending on the type of printer and material used, you may need to use tools like a scraper or spatula to assist in removing the object.

Post-Processing (Optional): Depending on your preferences and the requirements of your print, you may need to perform post-processing tasks such as sanding, painting, or assembly to achieve the desired final result.