What is the Structural Engineering in High-Rise Buildings?

Structural engineering in high-rise buildings involves the application of engineering principles and expertise to design, analyze, and ensure the safety and stability of the building’s structural systems. High-rise buildings are characterized by their significant height, which introduces various challenges that need to be addressed in the design and construction phases. Here are some key aspects of structural engineering in high-rise buildings:

1. Load Analysis: Structural engineers begin by examining the various loads that a high-rise building may encounter, such as dead loads (the building’s own weight), live loads (the weight of occupants and equipment), wind loads, seismic loads, and temperature fluctuations. Designing a sturdy and secure structure requires an understanding of how these loads interact and affect the building.

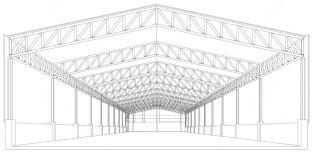

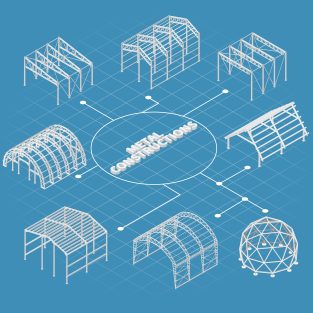

2. Structural Systems: Structural engineers select the best structural systems based on the architectural design and the particular needs of the structure. Reinforced concrete, structural steel, composite systems, and occasionally cutting-edge materials like carbon fiber-reinforced polymers are examples of common systems. These systems are chosen based on their longevity, load-bearing ability, and other pertinent characteristics.

3. Lateral Load Resistance: Wind and seismic activity can generate lateral forces to impinge on high-rise structures. To counteract these forces and avoid excessive swaying or structural damage, structural engineers build systems that resist lateral loads. Shear walls, bracing, moment frames, and tuned mass dampers are a few examples of these systems.

4. Foundation Design: A high-rise building’s foundation must be planned to securely disperse the weight of the structure to the earth. To choose the best foundation type, structural engineers take into account settlement analysis, bearing capability, and soil conditions. The heavy vertical loads are frequently supported by deep foundations like piles or caissons.

5. Wind Engineering: Wind can cause significant vibrations and movements in tall structures. Civil engineers work with wind engineering experts to conduct wind tunnel tests and computer simulations to understand how wind loads affect buildings. Next, appropriate countermeasures such as aerodynamic shapes and dampers are designed to mitigate these effects.

6 Seismic engineering: High-rise buildings located in seismic zones must be designed to withstand the movement of the ground during an earthquake. Structural engineers perform seismic analyzes to assess a building’s response to different levels of seismic activity. Design structures with sufficient ductility and strength to absorb and dissipate seismic energy.

7. Vertical Transportation: Structural engineers collaborate with architects and elevator consultants to integrate vertical transportation systems efficiently. They allocate space for elevators and escalators while considering their weight, movement, and impact on the building’s structure.

8. Construction methods: The construction of high-rise buildings often requires special construction methods such as slip formwork, snap formwork and prefabrication. Civil engineers ensure that these construction techniques are safely implemented and that the structural integrity of the building is maintained throughout the construction process.

9. Material Selection and Sustainability: Civil engineers evaluate material options not only for load-bearing capacity, but also for environmental impact and sustainability. In high-rise construction, it is important to choose materials with a high strength-to-weight ratio and a low carbon footprint.

10. Work with Architects: Civil engineers work closely with architects to ensure that the aesthetic and functional aspects of the building are consistent with the structural design. They find ways to incorporate structural elements into their architectural vision while maintaining safety and stability.

Importance of Structural Engineering in High-Rise Buildings

Structural engineering plays a crucial role in the design, construction, and safety of high-rise buildings. High-rise buildings are defined by their significant height, which brings about unique challenges and considerations that require specialized structural expertise. Here’s why structural engineering is of paramount importance in high-rise building projects:

1. Safety and stability: High-rise buildings are subjected to a variety of loads, including: B. Dead load (weight of the building itself), live load (stress on occupants and equipment), wind load, seismic load, temperature change. Structural engineers analyze these loads to ensure the stability and safety of buildings under various conditions. They design structural systems that can withstand these forces and maintain the integrity of the building.

2. Vertical and Lateral Loads: High-rise buildings are subject to both vertical and lateral loads. The latter is particularly pronounced due to wind and seismic forces. Structural engineers design lateral load-bearing systems such as shear walls, stiffeners, and moment frames to counteract the shaking and twisting that can occur in tall buildings.

3. Material Selection: Civil engineers must carefully select building materials that can withstand the various loads and environmental conditions of high-rise buildings. These materials include reinforced concrete, structural steel, composite systems, and advanced materials such as carbon fiber reinforced polymers. Correct selection of materials contributes to the durability and safety of the building.

4. Foundation Design: The foundation of a skyscraper should be designed so that the enormous weight of the structure is evenly distributed over the ground. The choice of foundation type (eg deep foundations such as piles or caissons versus shallow foundations) depends on the soil conditions of the site and the characteristics of the building. Civil engineers analyze soil surveys and perform geotechnical studies to determine appropriate foundation designs.

5 Wind and Seismic Considerations: High-rise buildings are particularly vulnerable to wind-induced vibrations and earthquakes. Structural engineers perform wind tunnel tests and seismic analyzes to understand how these forces affect buildings. Then design damping systems, tuned mass dampers, and other mitigation measures to control vibrations and prevent structural damage.

6. Vertical Transportation: High-rise buildings require efficient vertical transportation systems, including elevators and escalators. Civil engineers work with architects and elevator consultants to allocate space for the system, taking into account the system’s weight, movement, and impact on the building structure.

7. Space Efficiency: Every centimeter of space matters in a skyscraper. Civil engineers work closely with architects to optimize building floor plans while ensuring structural integrity. This includes designing innovative column and beam arrangements that create free space and minimize damage to functional areas.

8 Construction methods: The construction of high-rise buildings often requires complex construction methods such as slip formwork, snap formwork and prefabrication. Civil engineers ensure that these construction methods are safe to implement and that the building can withstand the stresses encountered during construction.

9. Integration of aesthetics and function: Skyscrapers are often iconic structures that contribute to a city’s skyline. Civil engineers work with architects to seamlessly integrate structural elements into a building’s aesthetic and functional design. It’s about finding innovative ways to bring architectural visions to life while maintaining structural integrity.

In summary, structural engineering is very important in the design and construction of skyscrapers to ensure safety, stability, durability and functionality. The unique challenges of high-rise buildings require expertise to manage the complexities associated with integrating vertical and lateral loads, foundation design, wind and seismic forces, and architectural and functional requirements.

What a structural engineer does?

A structural engineer specializes in designing, analyzing, and ensuring the stability, strength, and durability of buildings, bridges, towers, dams, and other structures. Their primary responsibilities include:

Designing structures: They create detailed plans and specifications for structures based on factors like load, materials, and environmental conditions.

Analyzing loads: They calculate and assess the loads that a structure will encounter during its lifespan, including factors like wind, earthquakes, and traffic.

Selecting materials: Structural engineers choose appropriate materials such as steel, concrete, wood, or composite materials based on factors like strength, cost, and availability.

Ensuring safety: They ensure that structures meet safety standards and codes to protect occupants and the public from hazards.

Collaborating with architects and construction teams: They work closely with architects, contractors, and other professionals throughout the design and construction process to ensure that the structure meets the intended design while remaining structurally sound.

Inspecting existing structures: Structural engineers assess the condition of existing structures, identifying any weaknesses or defects and recommending repairs or modifications to ensure safety and longevity.

Using computer-aided design (CAD) software: They utilize specialized software to model structures and analyze their behavior under various conditions.

What is the difference between a civil engineer and a structural engineer?

Civil engineering is a broad field that encompasses various disciplines, including structural engineering. While both civil engineers and structural engineers work in the construction industry and deal with designing and constructing buildings and infrastructure, there are some key differences between the two roles:

Scope: Civil engineering is a broad field that deals with the design, construction, and maintenance of infrastructure projects such as roads, bridges, dams, airports, and buildings. Structural engineering, on the other hand, is a subset of civil engineering that specifically focuses on the design and analysis of structures to ensure they can withstand loads and environmental stresses.

Focus: Civil engineers work on a wide range of projects, including transportation systems, water supply and drainage systems, environmental engineering, and geotechnical engineering. Structural engineers specialize in analyzing and designing the structural elements of buildings and other structures to ensure they are safe, stable, and durable.

Expertise: Civil engineers typically have a broader skill set and knowledge base that includes elements of structural engineering along with other disciplines such as transportation, environmental, and geotechnical engineering. Structural engineers have specialized expertise in structural analysis, design, and construction materials.

Responsibilities: Civil engineers are involved in the planning, design, construction, and maintenance of various types of infrastructure projects. They may oversee the work of structural engineers as well as professionals from other disciplines to ensure that projects meet design specifications, safety standards, and regulatory requirements. Structural engineers are primarily responsible for analyzing the structural integrity of buildings and other structures, determining appropriate construction materials and methods, and ensuring that structures comply with building codes and regulations.