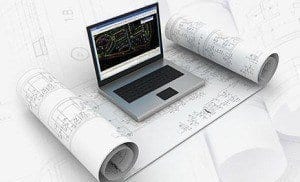

Rapid Prototyping offer advanced ability to design and fabricate models. Along with using proof-of-principle prototypes. Whereas in some cases, it uses functional components. Also, it adds well-established Additive Processes, whereby plastic parts are mostly built layer by layer directly from a 3D CAD model. Some of the standard techniques include:

Selective Laser Sintering (SLS)

Direct Metal Laser Sintering (DMLS)

Fused Deposition Modelling (FDM)

The Polyjet Process

Computer Numeric Control (CNC) machinery mainly uses a well-known subtractive process and uses machines, billets and other desired parts. Whereas on the other hand, it uses rapid prototyping processes that cover Injection Moulding and Casting. It uses master moulds that inject cast plastic or any other urethane parts.

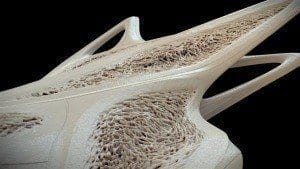

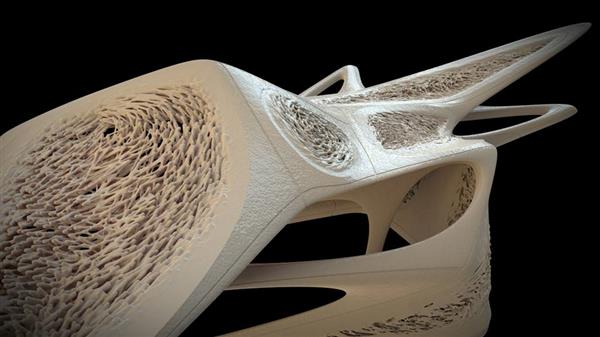

Several methods, techniques, and approaches are used that add rapid prototyping parts. It includes components that are developed each year. Some of the most exciting developments are shown below:

(CAD Innovations in Rapid Prototyping) FORD’S F3T RAPID STAMPING PROCESS

Ford Motor Company mainly uses sheet metal parts that assemble vehicles and develop world-renowned sheet metal fabrication. The process that takes a new design from a CAD model to a prototype can be time-consuming.

The latency increases the design iteration time, makes it highly cumbersome and excellent off prototypes and test-fit new designs. Recently, ford created a new rapid process, which they call the Ford Freeform Fabrication Technology (F3T). It’s a part of a three-year, $7.04 M, U.S. The department of Energy-funded effort mainly uses next-generation manufacturing and energy-efficient processes. The new short-run stamping technology offers low costs with fewer delivery times for low-quantity run sheet metal parts.

The process mostly begins with a CAD model, which creates a Computer Numeric Control (CNC) tool path and works similar to the path. It is used by a 3D printer with generating the part. It directs position with keeping in-depth dual-arm robot. It holds tools in both arms as the process sheets into shape. Additionally, it allows prototypes and small production that run cost-effectively with shorter lead times. The customization comes with viable design cost iterations, and it offers drastically reduced change. The short-run stamping process is used with bigger applications in various industries.

(CAD Innovations in Rapid Prototyping) LARGE-SCALE 3D PRINTERS

It’s a kind of exciting area of innovation used in rapid prototyping. It uses 3D printers for building models and working prototypes which were impossible until now. The 3D printers are capable of printing vehicles and provide tiny houses. The researchers at the Oak Ridge National Laboratory and Cincinnati Incorporated developed a printer capable of using Additive Processes by building the Stratis Car. The machine, named Big Area Additive Manufacturing (BAAM), makes a volume of 7′ x 13′ x 3′ along with a deposition rate of 40 lbs/hr against BAAM’s rate of 40 lbs/hr. The system supports to combines 3D printing along with CNC routing with the largest high-quality 3D printing. Also, the second generation of this technology, referred to as Bertha, feature a volume of 8′ x 20′ x 6′ and a 100 lbs/hr deposition rate.

The other researchers develop technologies that revolutionize the housing industry by using Additive Manufacturing and building structures. Massimo Moretti devoted his time by applying 3D printer technologies and providing rapid prototype solutions. It caters to the housing crisis in developing countries across the world.

Additionally, the project is known for the World’s Advanced Saving Project (WASP). It mimics the construction method of the Mud Dauber Wasp building its nest. The primary goal of the technology is to build houses that add no cost by using materials. They are readily available on-site in third-world countries.

The complete system is designed with two people that assemble a 3D printer within 2 hours. The researchers at Winsun New Materials allow China to spend USD 3.2M over 12 years by developing an enormous 3D printer.

The printer measures a whopping 6.6m tall, 10m wide and 150m long. The houses print layer by layer using a mixture of cement and glass fibres. It helps to create a solid composite structure. Recently, Winsun proved that it built ten houses of 200 square meters in size using recycled construction and industrial waste in less than a few hours at the cost of only $4,800 each.

3D PRINTED JET ENGINES

The scope of 3D printing has been confined to housing. It has extended to jet engines, which are extremely difficult to build, including many intricate parts machined from many features with high tolerances for a seamless assembly.

The researchers at the Monash Centre comes with an Additive Manufacturing. Australia has produced the first 3D printed jet engine. It is based on an auxiliary powered gas turbine engine from Safran, a French aerospace firm. The Monash Centre mainly uses Concept Laser’s X line 1000R 3D printer. A state-of-the-art industrial printer fabricates components from metal powder by using sizes up to 60cm x 40cm x 50cm.

Whatever your proof-of-principle prototype requires. It is a suitable rapid prototype method that exists by adding CAD model and material/finish selection that the Software delivers. STP files enable customers by bringing ideas to life. We at Australian Design and Drafting help individuals and companies alike in this endeavour. The possibilities come endless as the technology becomes more viable and extends large sheet metals.