Are you interested in designing mechanical systems and creating detailed technical drawings? If so, a career as a Mechanical Drafter might be the perfect fit for you. Mechanical drafters play a critical role in the design process, transforming concepts and ideas into clear, precise technical drawings used by engineers and manufacturers. In this step-by-step guide, we will walk you through how to pursue a career as a Mechanical Drafter, from educational requirements to job responsibilities and career growth.

What is a Mechanical Drafter?

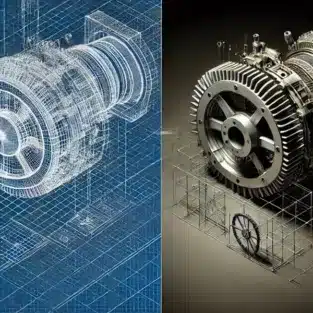

A Mechanical Drafter is a professional who uses computer-aided design (CAD) software to create detailed technical drawings for machinery, tools, and mechanical components. These drawings are used by engineers, manufacturers, and construction teams to build and assemble mechanical systems. Mechanical drafters typically work in industries like manufacturing, automotive, aerospace, construction, and engineering firms.

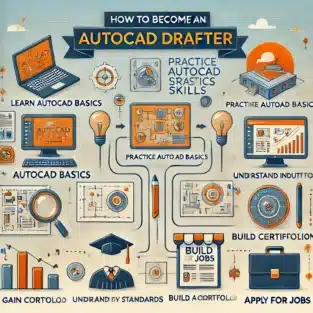

Step 1: Understand the Role of a Mechanical Drafter

Before jumping into any career, it’s crucial to understand the scope and expectations of the role. As a Mechanical Drafter, your job will involve:

- Creating technical drawings for mechanical systems, machines, and parts

- Translating concepts and ideas into detailed blueprints

- Using CAD software (like AutoCAD, SolidWorks, or Revit) to generate designs

- Working closely with engineers and designers to ensure accuracy and functionality

- Reviewing drafts and making revisions based on feedback from clients and project leads

- Understanding materials and manufacturing processes to ensure the feasibility of designs

The work you do as a Mechanical Drafter directly impacts the efficiency, quality, and success of mechanical projects. It’s essential to have a strong attention to detail and an understanding of mechanical engineering principles.

Step 2: Get the Right Education and Training

To start your journey as a Mechanical Drafter, the first step is obtaining the necessary education and training. While some entry-level positions might not require a formal degree, having a relevant educational background will give you a competitive edge.

- High School Diploma: Your journey starts with a high school diploma or GED. Focus on subjects like mathematics, physics, computer science, and design technology, as these will help build a solid foundation for drafting skills.

- Associate Degree in Drafting or Mechanical Design: A more specialized educational path is to pursue an associate degree in drafting or mechanical design. Many community colleges and technical schools offer programs that cover both traditional drafting techniques and modern CAD tools. During these programs, you’ll learn:

- CAD software

- Engineering principles

- Technical drawing conventions

- Mechanical design and materials science

- 3D modeling and simulation

- Certification: While not always required, earning certifications from recognized organizations like the American Design Drafting Association (ADDA) or Autodesk can improve your job prospects. These certifications validate your skills and knowledge in CAD software and drafting standards, which is important when competing for Mechanical Drafter Jobs.

Step 3: Gain Practical Experience

As with most technical careers, hands-on experience is key to becoming proficient as a Mechanical Drafter. After completing your education, consider internships, apprenticeships, or entry-level jobs in the drafting and design field to gain practical experience.

Internships allow you to work under experienced professionals, giving you insight into real-world applications of the tools and techniques you’ve learned. This experience helps you build a portfolio, which is essential when applying for Mechanical Drafter Jobs.

Many aspiring drafters also seek part-time or freelance work to build their resumes. This can help you enhance your skills, network with industry professionals, and even begin to offer Mechanical Drafter Services on a contract basis.

Step 4: Master CAD Software

One of the most important skills for a Mechanical Drafter is proficiency with CAD software. Many modern drafting tasks are done using computer-aided design tools, which are essential for creating accurate, detailed blueprints and designs. The most popular CAD programs include:

- AutoCAD: Widely used for drafting and designing 2D and 3D drawings.

- SolidWorks: Popular in engineering and mechanical design for creating 3D models.

- Revit: Used in the architectural, engineering, and construction industries.

- Inventor: A more advanced CAD program for 3D design and mechanical engineering.

Mastering these tools will allow you to create more precise and efficient designs, enhancing your employability as a Mechanical Drafter.

Step 5: Build a Portfolio

A strong portfolio is crucial for any designer or drafter. It showcases your skills, creativity, and the range of projects you can handle. As you gain experience, whether through internships, freelance work, or on-the-job projects, start compiling your best work into a professional portfolio.

Include a variety of project types, such as technical drawings for machinery, parts, or mechanical systems. Highlight the complexity and scope of your designs and emphasize your problem-solving abilities. A well-curated portfolio can make a significant difference when applying for jobs or offering Mechanical Drafter Services independently.

Step 6: Apply for Mechanical Drafter Jobs

Once you’ve completed your education, gained experience, and built your portfolio, you are ready to start applying for Mechanical Drafter Jobs. Start by researching companies that hire mechanical drafters, such as manufacturing firms, engineering companies, and architectural firms. Popular job search platforms like LinkedIn, Indeed, and Glassdoor can help you discover open positions.

When applying for jobs, tailor your resume and cover letter to highlight your relevant skills, experience, and certifications. Be prepared to provide samples of your work from your portfolio and demonstrate your proficiency with CAD tools.

Step 7: Advance Your Career

As with any career, there are plenty of opportunities for growth in the field of mechanical drafting. Here are some ways you can advance your career as a Mechanical Drafter:

- Specialize: Consider specializing in a specific area, such as automotive, aerospace, or robotics, to increase your value in the job market.

- Pursue Higher Education: You may choose to pursue a bachelor’s degree in mechanical engineering or a related field to transition into more advanced roles like mechanical design engineer.

- Stay Updated with New Technologies: The world of mechanical drafting is constantly evolving with advancements in technology and CAD software. Stay up-to-date with new tools and trends in the industry.

By continually learning and gaining experience, you can move up the career ladder to roles like Lead Drafter, Project Manager, or even start your own drafting service.

Conclusion

Becoming a Mechanical Drafter is an exciting and rewarding career path that offers a variety of job opportunities and growth potential. With the right education, hands-on experience, and proficiency in CAD software, you can pursue a successful career in this field. Whether you’re looking to work with engineering teams, join manufacturing firms, or offer independent Mechanical Drafter Services, this profession provides numerous pathways to success. If you’re ready to turn your design skills into a professional career, now is the time to start pursuing your dream of becoming a Mechanical Drafter.