AUSTRALIAN TECHNICAL DRAWING STANDARD

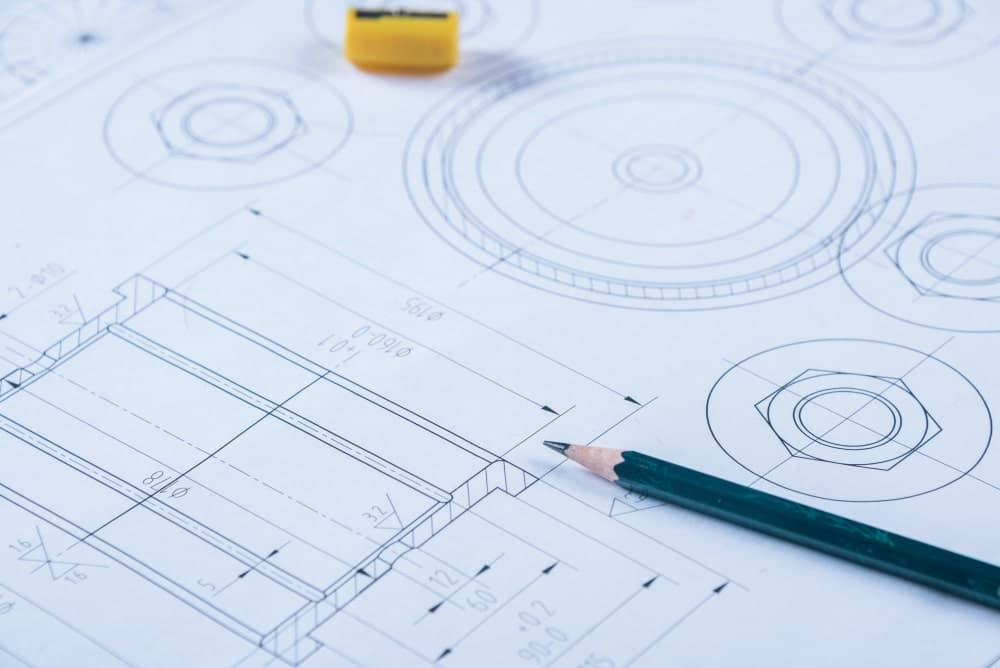

Technical drawing standards, also known as drafting standards or engineering drawing standards, are a set of rules and conventions that guide the creation, representation, and interpretation of technical drawings. These standards ensure consistency, clarity, and accuracy in the communication of technical information between engineers, designers, manufacturers, and other stakeholders involved in the production of products, structures, or systems.

AUSTRALIAN TECHNICAL DRAWING STANDARD

Several organizations and authorities worldwide have established technical drawing standards to facilitate efficient communication and understanding across industries. Some of the most commonly followed standards include:

- ISO (International Organization for Standardization) Standards: ISO 128 is an international standard for the general principles of presentation in technical drawings, covering topics like line types, dimensioning, and geometrical tolerances.

- ASME (American Society of Mechanical Engineers) Y14 Standards: Y14 standards are widely used in the United States for engineering drawings. The ASME Y14.5 standard, for instance, focuses on geometric dimensioning and tolerancing (GD&T).

- DIN (Deutsches Institut für Normung – German Institute for Standardization): DIN standards are popular in Germany and have had a significant impact on international technical drawing standards.

- ANSI (American National Standards Institute) Standards: ANSI provides various standards related to engineering drawings, including ANSI Y14.5 for GD&T.

- JIS (Japanese Industrial Standards): JIS standards are widely adopted in Japan and have influenced international technical drawing practices.

Technical drawing standards cover a wide range of elements, including:

- Line types and line weights

- Projection methods (e.g., orthographic projection, isometric projection)

- Dimensioning and tolerancing

- Title blocks and borders

- Symbols and abbreviations

- Geometric construction

- Material and surface finish representation

Benefits of technical drawing standards

Adhering to these standards ensures that technical drawings are clear, consistent, and universally understandable, regardless of the individual or team that creates or interprets them. This is particularly crucial in engineering and manufacturing, where precise specifications and measurements are vital for successful production and assembly. By following established technical drawing standards, professionals can avoid misinterpretation and errors, saving time and reducing costly mistakes in the design and manufacturing processes.

The use of technical drawing standards provides numerous benefits across various industries and disciplines. Some of the key advantages include:

- Clarity and Consistency: Technical drawing standards ensure a consistent and uniform approach to representing information on drawings. This clarity helps all stakeholders understand the design intent without confusion or misinterpretation, reducing errors and rework.

- Effective Communication: Standardized technical drawings facilitate effective communication between different teams, departments, and organizations. Engineers, designers, manufacturers, and suppliers can easily exchange information, resulting in smoother collaboration and project execution.

- Interoperability: Following established drawing standards promotes interoperability between different computer-aided design (CAD) systems and software. This compatibility allows data exchange across platforms, enhancing workflow efficiency and reducing compatibility issues.

- Streamlined Manufacturing: Clear and standardized technical drawings make it easier for manufacturers to understand the design requirements and produce components accurately. This reduces manufacturing errors and helps achieve consistent quality in the final product.

- Cost Savings: By minimizing errors, rework, and misunderstandings, technical drawing standards contribute to cost savings in the design and manufacturing processes. The reduction in waste and inefficiencies leads to improved project outcomes and increased productivity.

- Compliance and Regulation: Many industries, such as aerospace, automotive, and medical devices, have specific regulatory requirements for design documentation. Adhering to technical drawing standards ensures compliance with industry regulations and facilitates the approval process.

- Geometric Dimensioning and Tolerancing (GD&T): Technical drawing standards, such as ASME Y14.5 and ISO 1101, provide guidelines for GD&T, which enables precise and consistent specification of tolerances. GD&T enhances the functional communication of part requirements, allowing for more efficient manufacturing and assembly.

- Design Reuse: Standardized technical drawings make it easier to reuse and modify existing designs for similar projects. This speeds up the design process and promotes a more efficient use of resources.

- Training and Education: Technical drawing standards provide a structured framework for teaching and learning engineering drawing. They serve as a basis for training new engineers, drafters, and designers, ensuring a common understanding of best practices.

- Global Collaboration: International organizations and projects benefit from using widely accepted technical drawing standards, as they facilitate collaboration between teams from different countries, cultures, and languages.

Technical drawing services for industries involve creating accurate and detailed drawings, diagrams, and plans that are essential for the design, manufacturing, and construction of industrial products and processes. These drawings serve as a common language for engineers, architects, and other professionals involved in the industry to communicate and understand complex ideas.

Here are some key aspects of technical drawing services for industries:

- CAD (Computer-Aided Design): Technical drawings are typically created using specialized software known as Computer-Aided Design (CAD). CAD software allows precise and efficient creation, editing, and modification of drawings.

- 2D and 3D Drawings: Technical drawings can be presented in both two-dimensional (2D) and three-dimensional (3D) formats. 2D drawings are used for detailed representations of individual parts, while 3D models offer a more comprehensive view of the entire product or system.

- Engineering Drawings: These drawings are fundamental in industries like mechanical, electrical, civil, and architectural. They provide information about dimensions, tolerances, materials, and assembly instructions.

- Prototyping and Manufacturing: Technical drawings are used as blueprints for prototyping and manufacturing processes. They ensure that the product is built correctly, adhering to specifications.

- Architectural Drawings: In the construction industry, architectural drawings depict the layout, dimensions, and details of buildings and structures.

- Electrical and Electronic Drawings: These drawings illustrate the wiring, circuitry, and layout of electrical and electronic systems.

- Civil Engineering Drawings: Used in infrastructure projects, civil engineering drawings show details of roads, bridges, pipelines, and other civil structures.

- Product Design: Technical drawings play a crucial role in designing products, whether it’s consumer goods, machinery, or industrial equipment.

- Accuracy and Standards: Technical drawings must be highly accurate and adhere to specific industry standards and conventions to ensure compatibility and ease of interpretation.

- Collaboration and Communication: Technical drawings enable effective communication between different stakeholders, including engineers, designers, manufacturers, and clients.

- Updates and Revisions: As projects progress and evolve, technical drawings may require updates and revisions to reflect changes accurately.

In summary, technical drawing standards play a crucial role in enhancing communication, reducing errors, and promoting efficiency in the design and manufacturing processes. They form the foundation for clear, precise, and universally understood engineering drawings, benefiting industries and professionals across the world.