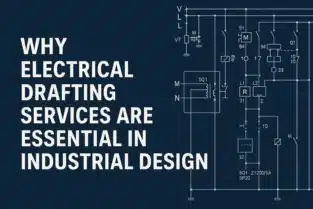

In the fast-paced world of industrial design, the role of electrical drafting services has become more vital than ever. As industries continue to integrate advanced technologies into their manufacturing and operations, the need for accurate, efficient, and standards-compliant electrical designs is growing rapidly. Electrical drafting plays a key role in ensuring that industrial systems are functional, safe, and scalable from the planning stage to final execution.

In this blog, we will explore why electrical drafting services are a fundamental component of industrial design, and how they help engineers, manufacturers, and project managers maintain high standards in every stage of development.

What Are Electrical Drafting Services?

Electrical drafting services involve the creation of detailed technical drawings and documentation for electrical systems. These drawings include wiring diagrams, circuit layouts, panel schedules, conduit layouts, and power distribution systems. They are created using CAD (Computer-Aided Design) software and follow industry standards such as IEC, NEC, or ANSI.

Professionals in this field transform basic design concepts into accurate digital blueprints that electricians, engineers, and construction teams rely on for implementation.

The Role of Electrical Drafting in Industrial Design

1. Accurate Representation of Electrical Systems

Industrial design often involves large-scale electrical systems with complex interconnections between machines, control systems, and power sources. Electrical drafting services provide precise diagrams that detail every component, wire, and connection. This level of accuracy minimizes guesswork and ensures smooth execution during installation.

2. Compliance with Industry Standards

Industrial electrical systems must comply with strict safety and regulatory standards. Drafting professionals understand national and international codes and incorporate them into their designs. Whether it’s the National Electrical Code (NEC) in the United States or the International Electrotechnical Commission (IEC) standards globally, compliance is ensured through professional drafting.

3. Improved Project Planning and Communication

Electrical drafting documents serve as a universal language between designers, engineers, contractors, and clients. These clear and standardized drawings enhance collaboration and reduce misunderstandings during planning, installation, and maintenance.

4. Time and Cost Efficiency

By utilizing electrical drafting services, companies can save time and reduce costs. Well-drafted electrical plans prevent errors during construction, avoid material wastage, and reduce downtime during maintenance. Early detection of design flaws through drafting can prevent costly rework later in the project.

5. Integration with Mechanical and Structural Systems

In industrial design, electrical systems do not function in isolation. They must be integrated with mechanical and structural components. Electrical drafting services ensure that power supply, grounding, and control systems are correctly coordinated with other disciplines to avoid conflicts during installation.

6. Support for Automation and Smart Technologies

Modern industrial environments are increasingly automated. From programmable logic controllers (PLCs) to IoT-enabled sensors, electrical systems must be compatible with digital technologies. Electrical drafting helps visualize these integrations clearly, allowing for seamless implementation of smart systems.

Industries That Benefit from Electrical Drafting Services

Several industrial sectors rely heavily on electrical drafting services, including:

- Manufacturing Plants – For power distribution, automation, and control panels.

- Oil and Gas Facilities – For hazardous area electrical systems and instrumentation.

- Construction and Infrastructure – For electrical layouts in industrial buildings.

- Water Treatment Plants – For control systems and power management.

- Energy and Renewable Sectors – For solar, wind, and electrical substation designs.

Key Deliverables in Electrical Drafting Services

A comprehensive electrical drafting package typically includes:

- Single-line diagrams

- Wiring diagrams and schematics

- Power distribution layouts

- Panel schedules

- Lighting and outlet plans

- Grounding and earthing plans

- Conduit and cable tray layouts

- Bill of materials (BOM)

These documents are crucial for installation, inspection, and future maintenance.

The Rise of CAD and BIM in Electrical Drafting

Today’s electrical drafting services rely heavily on advanced tools like AutoCAD Electrical, Revit MEP, and SolidWorks Electrical. These tools allow for 2D and 3D representations of systems, clash detection with other services, and integration with Building Information Modeling (BIM).

By using these technologies, electrical drafters can create intelligent, data-rich drawings that improve accuracy and adaptability in evolving project environments.

Why Outsourcing Electrical Drafting Services Makes Sense

Many industries choose to outsource their drafting needs to specialized providers. Here’s why:

- Access to skilled professionals without the cost of full-time staff.

- Quick turnaround time for urgent projects.

- Cost-effective solutions that reduce overhead.

- Scalability for handling both small and large-scale projects.

Outsourcing ensures that companies focus on core activities while drafting experts handle technical documentation with precision.

Conclusion

Electrical drafting services are not just technical documentation—they are the backbone of safe, compliant, and efficient industrial design. From concept to execution, electrical drafts bring clarity, accuracy, and standardization to every project. With the complexity of modern industrial systems, having professionally created electrical drawings is no longer optional—it is essential.

Whether you’re setting up a new manufacturing plant, automating an existing facility, or planning a major infrastructure upgrade, investing in reliable electrical drafting services can dramatically enhance project outcomes.

What are electrical drafting services?

Electrical drafting services involve creating detailed technical drawings and schematics for electrical systems. These drawings include layouts for power distribution, lighting systems, wiring diagrams, panel schedules, and circuiting, which are essential in planning and implementing electrical infrastructure in industrial design.

Why are electrical drafting services important in industrial projects?

In industrial design, precision is critical. Electrical drafting ensures accuracy, safety, compliance with electrical codes, and efficient use of resources. These services support the coordination between engineers, contractors, and manufacturers to avoid costly errors and rework.

What industries benefit most from electrical drafting services?

Industries such as manufacturing, oil and gas, automotive, aerospace, pharmaceuticals, and construction heavily rely on electrical drafting to design safe and effective electrical systems for plants, factories, and production facilities.

How do electrical drafting services contribute to safety?

Electrical drafting provides exact blueprints for system installation and maintenance, minimizing the risk of electrical faults, overloads, and fire hazards. Clear documentation ensures proper insulation, grounding, and circuit protection are in place.

What types of drawings are included in electrical drafting services?

Typical drawings include:

Power and lighting layouts

Cable and wiring diagrams

Single-line and multi-line diagrams

Control panel layouts

Schematic diagrams

Load schedules and panel board details

How does electrical drafting improve project efficiency?

Accurate drafting streamlines communication between project stakeholders, prevents design clashes, enables faster permitting, and accelerates construction timelines. It also allows early detection of issues, reducing delays and costs.

Can electrical drafting help with regulatory compliance?

Yes. Electrical drafting services ensure designs follow local and international standards such as NEC, IEC, or IEEE. This compliance is crucial for securing permits and passing inspections in industrial setups.

Is CAD software used in electrical drafting?

Absolutely. Modern electrical drafting heavily relies on CAD software like AutoCAD Electrical, Revit, or EPLAN to create precise and editable drawings, enhancing accuracy, integration, and documentation.

What’s the difference between electrical drafting and electrical design?

Electrical design involves engineering decisions such as load calculation, equipment selection, and system layout planning. Electrical drafting translates those decisions into detailed drawings used for implementation, installation, and maintenance.

Why outsource electrical drafting services?

Outsourcing offers access to skilled drafters, cost savings, quicker turnaround, and the latest software tools. It allows industrial firms to focus on core operations while ensuring high-quality, code-compliant electrical documentation.

What is electrical drafting and why is it important in industrial design?

Electrical drafting is the process of creating precise technical drawings and documentation for electrical systems. In industrial design, electrical drafting ensures that all electrical layouts, components, and systems are correctly designed and documented. It helps in visualizing the project before implementation, saving time, cost, and preventing errors during construction.

How does electrical drafting contribute to industrial efficiency?

Electrical drafting improves efficiency by clearly detailing where each component goes and how systems are interconnected. This minimizes confusion during installation and maintenance. It streamlines collaboration between engineers, architects, and technicians, reducing downtime and eliminating expensive rework in industrial environments.

3. What are the main components of electrical drafting in industrial design?

In industrial settings, electrical drafting includes:

Electrical layouts and wiring diagrams

Lighting plans

Power distribution layouts

Control systems schematics

Panel board schedules

Load analysis and circuiting plans

These components help engineers ensure the electrical infrastructure aligns with industrial needs and safety regulations.