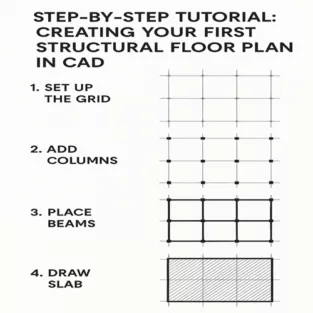

Creating a structural floor plan in CAD might sound like rocket science at first, but trust me—it’s totally doable with the right steps. If you’re diving into structural design and drafting services for the first time, this guide is your go-to resource. Let’s break it down and build your skills, one step at a time!

What is a Structural Floor Plan?

Definition and Purpose

A structural floor plan shows the bones of a building. It focuses on how the building holds itself up—beams, columns, slabs, load-bearing walls, and foundations.

Differences from Architectural Plans

While architectural plans focus on spaces, aesthetics, and user experience, structural plans deal with physics. No pretty tiles or lighting layouts here—just strength and stability.

Understanding the Basics Before You Start

Load-Bearing Elements

You need to know what parts of your design carry the most weight—columns, beams, and structural walls.

Beam and Column Layout

These are the framework of your building—placing them wrong could lead to structural failures.

Slabs and Reinforcements

Slabs are the horizontal components (like floors and ceilings), and they need reinforcement to prevent bending and breaking.

Step 1 – Setting Up Your Workspace

Units and Scales

Start by setting your units (metric or imperial) and scale according to the local standards.

Grid Settings and Templates

Grids help in aligning elements properly. Use templates for consistent results—especially handy when working with large projects.

Step 2 – Import or Draw the Base Layout

Using Architectural Plans as a Reference

Usually, structural floor plans are built over existing architectural plans. Import them to guide your drawing.

Drawing Walls and Structural Elements

Begin sketching the walls that will bear loads. Use line or polyline tools for precise placement.

Step 3 – Placing Columns and Beams

Identifying Column Positions

Columns typically align with corners or intersections of load-bearing walls. Place them symmetrically when possible.

Aligning Beams with Columns

Beams connect the columns and support the slab. Make sure the spacing and alignment are clean and logical.

Step 4 – Designing Slabs

Types of Slabs

- One-way slabs

- Two-way slabs

- Flat slabs

Detailing Slab Reinforcement

Use hatch or line patterns to show rebar layout, including spacing and thickness.

Step 5 – Adding Dimensions and Annotations

Dimensioning Best Practices

Don’t clutter your plan. Use consistent units and spacing. Group related dimensions together.

Labeling Structural Elements

Clearly label each element—beams (B1, B2), columns (C1, C2), and so on. This makes referencing easy during construction.

Step 6 – Checking and Validating Your Plan

Cross-Checking Alignment

Make sure everything lines up—columns, beams, walls. Misalignments can cause on-site issues.

Clash Detection and Load Path Review

Check for elements overlapping improperly and review how loads are transferred through the structure.

Step 7 – Exporting and Printing

File Formats

Export in DWG for CAD, PDF for sharing, and DXF for CNC work.

Plotting and Sharing with Teams

Use proper title blocks and scales before printing. Coordinate with architects and MEP teams.

Tips for Accuracy and Efficiency

Layer Management

Use different layers for beams, columns, slabs, etc., with color coding. It’ll save you from a ton of confusion later.

Using Blocks and Templates

Reuse components like column blocks or dimension styles. It’s a huge time-saver.

Tips for Accuracy and Efficiency

Layer Management

Use different layers for beams, columns, slabs, etc., with color coding. It’ll save you from a ton of confusion later.

Using Blocks and Templates

Reuse components like column blocks or dimension styles. It’s a huge time-saver.

Benefits of Using Structural Design and Drafting Services

Time-Saving

These services streamline your workflow by providing ready-to-use floor plans.

Expert Guidance and Precision

They know all the codes, tricks, and traps. When in doubt, it’s smart to outsource.

Common Mistakes to Avoid

Skipping Structural Details

Leaving out reinforcements or slab types is a recipe for disaster. Always be thorough.

Not Coordinating with Other Disciplines

Your structural plan should sync with architectural, plumbing, and electrical plans. Miscommunication here can be costly.

Conclusion

And there you have it—a complete step-by-step tutorial on creating your first structural floor plan in CAD. Whether you’re a beginner or brushing up your skills, these fundamentals will get you started on the right foot. Don’t rush the process, and remember: accuracy today saves time (and money) tomorrow.

What software is best for structural floor planning in CAD?

AutoCAD is a great starting point, but Revit and Tekla are better for advanced structural drafting.

Do I need architectural plans before making a structural plan?

Yes, architectural plans guide the layout of structural elements like columns and beams.

How long does it take to create a basic structural floor plan?

If you’re new, it might take a few hours. With practice or using Structural Design and Drafting Services, it’s much faster.

Can I design slabs without reinforcement details?

Technically yes, but it’s not recommended. Reinforcement is critical for slab performance and safety.

Why use Structural Design and Drafting Services?

They bring in expert knowledge, ensure compliance with standards, and deliver accurate, ready-to-use plans.