Effective communication is the foundation of a successful civil engineering project. One of the most critical tools for conveying design intent, project scope, and technical details to clients is through civil engineering drawings. These drawings serve as a universal language that clients, contractors, and engineers can understand, even if they don’t have a technical background. Improving how you use civil engineering drawings to communicate with clients can greatly enhance the clarity, efficiency, and outcome of your projects.

Civil Engineering Drawings

In this blog, we will explore practical ways to use civil engineering drawings to improve communication and ensure that your clients are fully informed at every stage of the project.

1. Simplify Complex Information for Client Understanding

Clients often lack the technical expertise that engineers possess, so simplifying complex civil engineering drawings without losing essential information is crucial. By using clear labeling, easy-to-read legends, and straightforward annotations, you can help your clients understand the drawings without feeling overwhelmed by jargon or overly detailed technical information.

Best Practices:

- Use simple and intuitive symbols for key features.

- Provide a legend or glossary to explain any necessary technical terms.

- Highlight the most important elements of the design, such as load-bearing structures or critical utilities, so that clients can easily identify them.

2. Incorporate Visual Aids and 3D Models

While traditional 2D civil engineering drawings are important, adding visual aids like 3D models can significantly improve client understanding. Clients often have a hard time interpreting flat drawings, especially when it comes to imagining how a design will look in reality. By supplementing your 2D plans with 3D models, you can offer a more immersive and intuitive way for clients to visualize the final project.

How It Helps:

- 3D models provide a real-world perspective of the project.

- Clients can see how different elements fit together in a tangible way.

- You can walk clients through different design phases or areas of the project virtually, offering better insights and engagement.

3. Ensure Clarity in Revisions and Updates

Civil engineering projects often require changes during the design phase, which means revisions to the drawings. Ensuring clear communication with clients during these updates is essential to avoid misunderstandings. Keeping your drawings well-organized and documenting all revisions ensures that the client remains up to date with any changes that occur throughout the project.

Tips for Clear Communication in Revisions:

- Use a version control system to track updates and ensure the client is looking at the most current set of drawings.

- Clearly mark revisions in a different color or with revision clouds, so the client can easily spot the changes.

- Accompany revised drawings with a brief summary or explanation of the changes, ensuring the client understands the impact on the project.

4. Use Consistent Drawing Standards

Standardizing your civil engineering drawings helps establish a consistent way of communicating across different projects and with various clients. When your clients become familiar with your drawing style and format, they will have an easier time navigating and understanding future projects. This consistency also reduces confusion and ensures that no vital details are overlooked.

Elements to Standardize:

- Line weights and styles

- Text fonts and sizes

- Title blocks and annotations

- Layers for different types of information (structural, electrical, mechanical)

Establishing and adhering to these standards in all your projects increases professionalism and reduces the chances of miscommunication.

5. Focus on Accurate and Detailed Annotations

Annotations are a key component of civil engineering drawings, offering clients additional explanations of specific design features. Ensuring your drawings have detailed, accurate annotations can make the difference between a client understanding the project and missing out on crucial details.

Best Practices for Annotations:

- Use concise but informative text to describe important design elements.

- Avoid over-explaining; stick to what the client needs to know, such as key measurements, materials, and construction techniques.

- Place annotations close to the elements they refer to, to avoid confusion or misinterpretation.

6. Provide Digital Access to Civil Engineering Drawings

In the digital age, clients appreciate the ability to access project drawings from anywhere, at any time. Offering a civil engineering drawings service that includes digital delivery ensures that your clients can review project designs at their convenience. Additionally, digital drawings allow for easy updates and sharing, making collaboration smoother.

Digital Solutions to Consider:

- Use cloud-based platforms for sharing drawings, ensuring clients always have access to the latest versions.

- Provide high-resolution PDFs or CAD files that clients can review and zoom into for detail.

- Allow clients to leave comments or feedback directly on digital drawings, improving the flow of communication and reducing delays.

7. Schedule Regular Review Meetings

No matter how clear the civil engineering drawings are, face-to-face or virtual meetings are still invaluable for reinforcing communication. Regular review meetings with clients help clarify any points of confusion and ensure that they are aligned with the project’s direction. It also gives you the opportunity to walk clients through the drawings in real-time, providing immediate clarification for any questions or concerns they may have.

Meeting Best Practices:

- Schedule review sessions after major design milestones.

- Encourage clients to ask questions during these meetings and clarify any uncertainties they have about the drawings.

- Use this time to explain any complex aspects of the design that might not be obvious from the drawings alone.

8. Tailor the Drawing Presentation to Your Audience

Clients differ in their technical understanding and involvement in the project. Some clients may prefer high-level overviews, while others may want more detailed information. Tailoring your civil engineering drawings service to meet the needs and preferences of each client ensures better communication and satisfaction.

Steps for Tailoring Your Drawings:

- Identify the technical level of your client and adjust your communication style accordingly.

- Provide simplified or summary drawings alongside detailed ones, depending on client preference.

- Offer to explain certain technical aspects in more detail if a client seems unsure.

Conclusion

Improving communication with clients using civil engineering drawings requires careful consideration of how these drawings are presented and understood. By simplifying complex information, incorporating 3D models, ensuring clarity in revisions, maintaining drawing standards, and tailoring your presentation to the client, you can enhance client communication and project success. Offering a robust civil engineering drawings service that caters to these needs will set your firm apart as a client-focused, reliable partner in engineering design.

What is AutoCAD for civil engineering?

AutoCAD is a widely used software application that plays a vital role in civil engineering. It is primarily used for computer-aided design (CAD) and drafting, allowing civil engineers to create, modify, analyze, and optimize detailed technical drawings and designs for infrastructure and construction projects. AutoCAD’s versatility makes it a cornerstone for the planning and design of roads, bridges, buildings, water systems, and other civil engineering projects.

Key Uses of AutoCAD in Civil Engineering:

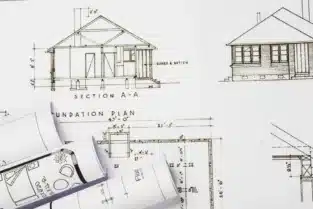

Drafting and Drawing Creation: AutoCAD is used to develop 2D and 3D drawings of civil engineering structures. Engineers can create plans, sections, elevations, and detailed layouts with high precision, helping communicate complex project information effectively.

3D Modelling: AutoCAD supports 3D modeling, which enables civil engineers to visualize how the final project will look. This is especially useful for large-scale projects like highways, tunnels, and urban infrastructure.

Site Planning and Design: For tasks like terrain modeling, site planning, and grading, AutoCAD provides engineers with tools to design roads, plot land areas, and analyze topography to ensure accurate and efficient site layouts.

Surveying and Mapping: AutoCAD integrates with surveying equipment, allowing civil engineers to import real-world data such as GPS coordinates, topographical data, and elevation points. This helps in creating accurate site maps and layout plans.

Do civil engineers draw plans?

Yes, civil engineers do draw plans, but this task is often carried out in collaboration with drafting technicians or CAD (computer-aided design) specialists. Civil engineers are responsible for the design and planning of infrastructure projects like roads, bridges, buildings, and water systems. To communicate their design ideas and ensure the proper execution of projects, they create detailed civil engineering drawings or plans.

Types of Plans Civil Engineers Create:

Site Plans: These drawings show the overall layout of a project site, including property boundaries, building locations, access roads, utilities, and landscaping. Site plans are essential for coordinating the placement of all physical components of a project.

Structural Plans: Civil engineers create structural drawings that detail the design of load-bearing elements like beams, columns, and foundations. These plans ensure that buildings, bridges, and other structures can safely withstand the loads they will face.

Grading and Drainage Plans: For land development and roadway projects, engineers design grading plans that show how the ground should be sloped for proper drainage. They also create drainage plans that include water flow management through pipes, culverts, and storm drains.

Utility Plans: These show the layout of essential utilities, including water supply, sewage systems, electrical lines, and telecommunications infrastructure. Civil engineers ensure that utilities are safely and efficiently routed throughout the project area.