AutoCAD conversion is essential for companies across various industries, providing a seamless way to transition between file types, improve accuracy, and enhance collaboration on complex projects. In this blog, we’ll cover the key aspects of AutoCAD conversion, its importance, common conversion types, and tips for optimizing the process.

Why AutoCAD Conversion Matters

AutoCAD conversion is the process of transforming design data into compatible formats, ensuring that all stakeholders—engineers, architects, and designers—can access and use the information effectively. Converting files into AutoCAD-compatible formats is essential in maintaining the accuracy and integrity of design data. Whether it’s legacy data or newer file formats, AutoCAD conversion enables organizations to work with historical records, share files with collaborators, and meet project requirements seamlessly.

Common Types of AutoCAD Conversions

- PDF to AutoCAD

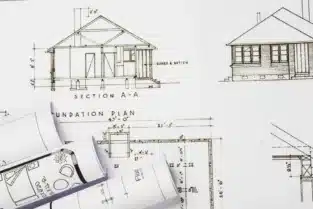

Converting PDFs to AutoCAD is among the most common needs in architecture and engineering. While PDFs provide a snapshot of design documents, converting them into DWG or DXF files allows for editing and modification in AutoCAD. This is especially useful for updating designs, creating as-built drawings, or making revisions. - Image to AutoCAD

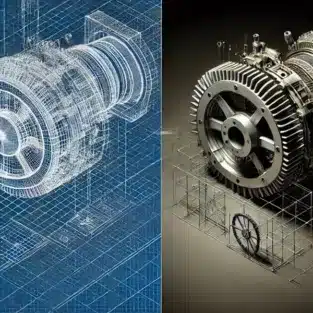

This process involves converting images (JPEG, PNG, TIFF) into vector-based AutoCAD files. Image conversion is valuable when working with scanned blueprints or hand-drawn sketches that need digital precision. Using tools such as raster-to-vector conversion software can make this process faster and more accurate. - 2D to 3D Conversion

Many industries are moving toward 3D modeling to create highly detailed and accurate designs. Converting 2D AutoCAD drawings into 3D models provides a more comprehensive view of projects, improving analysis, visualization, and accuracy in construction, manufacturing, and design. - Revit to AutoCAD

Revit is commonly used for BIM (Building Information Modeling) projects, but there may be situations where a Revit file needs to be converted to AutoCAD for use by team members who work within an AutoCAD environment. This conversion allows for easier cross-platform collaboration. - Point Cloud to AutoCAD

In industries where laser scanning and 3D measurements are essential, point cloud data can be converted into AutoCAD formats. This is particularly beneficial for renovation projects or when precise site measurements are required.

Key Benefits of AutoCAD Conversion

- Enhanced Collaboration

AutoCAD conversion ensures that data can be shared in a compatible format, enabling teams to collaborate effectively. Cross-disciplinary projects often involve stakeholders using different software platforms; converting files into AutoCAD-compatible formats ensures all team members have access to accurate information. - Data Preservation

Converting legacy data into AutoCAD formats allows businesses to maintain and preserve historical information, ensuring it’s available and usable in future projects. This is especially important for industries with regulatory requirements for archiving project data. - Improved Accuracy and Consistency

Manual re-drawing of designs from incompatible formats can lead to errors and inconsistencies. AutoCAD conversion minimizes this risk, ensuring that designs are transferred accurately and efficiently without any loss of detail. - Cost and Time Efficiency

Automating conversion processes reduces the need for manual rework and accelerates project timelines. Instead of redrawing or creating designs from scratch, conversions allow for immediate use and further development, resulting in significant time and cost savings.

Tips for Successful AutoCAD Conversion

- Use Specialized Conversion Tools

Numerous software tools are available to facilitate AutoCAD conversions. Using dedicated conversion software ensures higher accuracy and reduces the likelihood of errors. Tools such as AutoCAD itself, as well as third-party solutions, can efficiently handle various conversion formats, improving productivity and reliability. - Check for File Compatibility

Not all file types are directly compatible with AutoCAD. Before converting, verify the compatibility between the source and target file formats to ensure a smooth conversion. This may involve pre-processing or cleaning up files to ensure they translate accurately. - Optimize and Clean Up Files Post-Conversion

Once a file has been converted, it’s crucial to review and clean it up in AutoCAD. Conversion processes may introduce artifacts or misalignments; therefore, verifying dimensions, line work, and object integrity will ensure the converted file is usable and meets project standards. - Work with an Experienced Conversion Partner

If your company regularly handles large volumes of conversions or complex projects, consider partnering with an AutoCAD conversion service provider. Professionals with experience in CAD conversions bring expertise that can improve accuracy and efficiency, especially with challenging file types or large data sets. - Document the Process

Keeping a record of the conversion process, including any challenges or settings used, can be valuable for future conversions. This documentation helps standardize procedures, making the process more efficient and repeatable over time.

AutoCAD Conversion Services: Choosing the Right Provider

For companies looking to outsource AutoCAD conversions, selecting the right service provider is critical. Here are factors to consider:

- Experience and Expertise

Look for providers with proven expertise in AutoCAD conversion and a history of delivering high-quality, accurate conversions. A knowledgeable team will be able to handle complex file formats and provide solutions that fit your project needs. - Service Offerings and Capabilities

Not all conversion services offer the same capabilities. Check if the provider can handle the types of conversions you need, such as 2D to 3D, image to AutoCAD, or point cloud conversions. It’s beneficial to work with a provider who offers a range of services and flexibility. - Turnaround Time

In fast-paced industries, turnaround time is crucial. Make sure your service provider can meet your project deadlines and offer quick yet accurate conversions. - Quality Control

Quality control processes are essential in ensuring that converted files meet industry standards and project requirements. A reputable provider should have quality assurance measures in place, such as double-checking files for accuracy and consistency. - Data Security and Confidentiality

With sensitive project data involved, ensure your service provider follows strict data security protocols. Ask about their data handling and storage policies to confirm they can safely manage your files.

Conclusion

AutoCAD conversion is more than just transforming files; it’s about enhancing collaboration, preserving data integrity, and improving project efficiency. With the right tools, processes, and partnerships, AutoCAD conversion can streamline workflows and ensure that design data is accessible to everyone who needs it. Whether you’re converting PDF files, transitioning 2D drawings into 3D models, or working with legacy data, understanding the fundamentals of AutoCAD conversion helps companies achieve greater accuracy, save time, and reduce costs.

By following best practices and considering professional AutoCAD conversion services, your organization can maximize the benefits of seamless data compatibility across projects. In a world where design data is essential to project success, effective AutoCAD conversion is a powerful asset that keeps your team aligned and your projects on track.

How do I convert a drawing to CAD?

Converting a drawing to CAD involves taking a physical drawing, an image file, or a PDF, and translating it into a digital format that can be edited within CAD software, like AutoCAD. Here’s a step-by-step guide to help you with this process:

1. Digitize Your Drawing (If on Paper)

Scan the Drawing: If you have a hand-drawn or printed drawing, start by scanning it at a high resolution (300 DPI or higher) to capture all details. Save the scanned image as a PDF, JPEG, or TIFF.

Check the Image Quality: Ensure the scanned file is clear, without any smudges or distortions, as this will impact the quality of your CAD conversion.

2. Choose a CAD Conversion Method

You can convert a drawing to CAD either manually (by tracing) or automatically (using specialized software).

Method 1: Automatic Conversion Using Software

Use Raster-to-Vector Software: Software like AutoCAD (with its PDF import feature), Scan2CAD, or Adobe Illustrator can automatically convert images or PDFs to vector files.

Import into AutoCAD:Open AutoCAD, go to the “Insert” tab, and choose “Attach” to import your PDF or image.

Once attached, select the imported file and use AutoCAD’s “PDF Import” or similar feature to convert the lines into editable vector objects.

Clean Up the Conversion: After conversion, inspect the file for any inaccuracies, overlapping lines, or unneeded elements. Correct any errors and adjust line thicknesses or scales as needed.

How do I convert a CAD file?

Converting a CAD file usually means changing its format (for example, converting a DWG file to a DXF, PDF, STL, or other formats). This can be done directly in CAD software or with specialized conversion tools. Here’s a step-by-step guide to converting a CAD file effectively:

1. Identify the Target Format

Determine the format you need to convert your CAD file to, based on the software you or your collaborators will use. Common conversions include:

DWG to DXF: To maintain compatibility across various CAD programs.

DWG/DXF to PDF: For easy viewing and sharing with clients or stakeholders.

DWG/DXF to STL: For 3D printing.

DWG/DXF to STEP or IGES: For sharing with 3D modeling or CAM software.

2. Use the Built-In Export/Save As Feature in CAD Software

Most CAD programs, like AutoCAD, Fusion 360, and SolidWorks, have built-in options to export or save files in different formats.

AutoCAD:

Open the DWG or DXF file you want to convert.

Go to File > Save As or Export.

Choose the desired format from the dropdown (e.g., PDF, DXF, DWF, etc.).

Adjust any specific options related to the output format (e.g., line weights for PDFs, resolution for STL files).

Save the file in the new format.

Fusion 360:

Open the model or design.

Go to File > Export.

Select the file type you need (e.g., STEP, IGES, STL).

Choose additional settings for format-specific options.

Save or export the converted file.

SolidWorks:

Open the CAD file you want to convert.

Select Save As.

Choose the desired format, such as DXF, STEP, or IGES, from the dropdown menu.

Customize the export settings if needed, then save.