Construction projects are the keys to the creation of a modern world. They need immense planning and architectural design to create the most efficient and robust structures.

WHAT IS STRUCTURAL STEEL DETAILING?

Structural steel detailing is a part of drawing and model development. The contractors and fabricators must hold it in high regard while working with residential and commercial construction projects. Now that you might wonder what structural steel detailing stands for and why it is essential, here is all you need to know about it.

Structural steel detailing is the method of creating drawings and designs for steel components of structural projects. The steel components include steel columns, steel joists, trusses, handrails, metal decking, stairs, etc.

Structural steel detailing of these components ensures the strength and integrity of structures. On failing to undergo structural steel detailing, the construction projects might prove inefficient and pose numerous threats to life and property.

Hence, engineers, steel fabricators, contractors, and architects use structural steel detailing to make reliable and durable steel components to erect structures.

What are the types of structural steel detailing?

Two types of structural steel detailing are involved in the construction industry. The drawings used in the process are divided into erection and shop drawings.

- Erection drawings: erection drawings are essential components of structural steel detailing. They involve the dimensional and geographical planning and positioning of the steel components of structures. It helps install the steel components and the external works required on them.

- Shop drawings: shop drawings deal with further detailing of the steel components. It involves illustrating columns, joints, and steel beams, considering the components’ material specifications, size, and dimensions. Structural detailing steel shop drawings help in the assembly of the steel components.

What is the importance of structural steel detailing?

Structural steel detailing is significant in the construction industry. Numerous reasons support the statement. It provides a well-designed plan for construction involving steel components. It not only helps contractors and engineers erect a versatile structure but also prevents accidents that could arise due to miscalculations in the size and dimensions of the components. It also links the engineers, contractors, fabricators, and architects involved at different project stages to keep them on the same page.

How does the computer-aided design make structural steel detailing efficient?

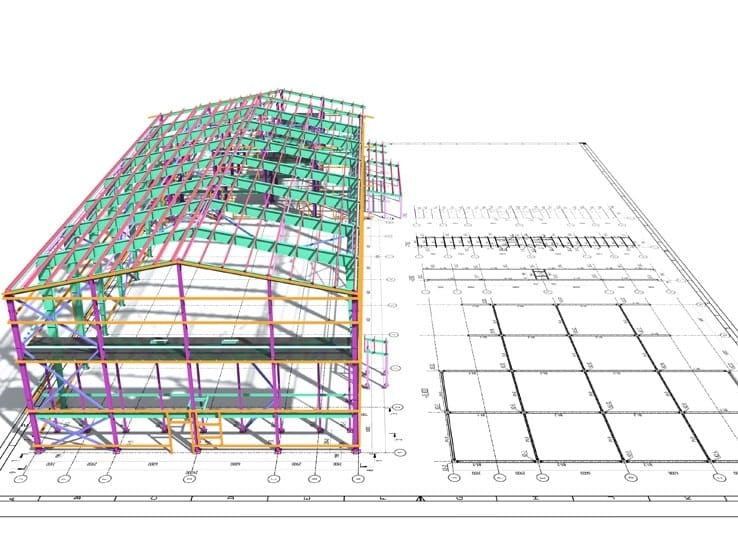

Computer-aided design helps automate the designing and drawing of various steel components. It provides facilities for both 2D and 3D drawings with a top-notch presentation. Moreover, the measurements and calculations are precise and accurate due to the least human error. Hence, ultimately it reduces manual effort and time used in construction projects.

In fact, we use premium software like TEKLA, Solidworks and inventor to make these designs. It helps us attain perfection and deliver quality work to our customers.

Structural steel detailing for Industries

Structural steel detailing is a crucial process in the construction and manufacturing industries, involving the creation of detailed drawings and documents that guide the fabrication and erection of steel structures. These structures can include buildings, bridges, industrial plants, warehouses, and more. The goal of structural steel detailing is to provide accurate and comprehensive information to ensure the successful construction of the project. Here’s an overview of the process and its key components:

- Initial Information Gathering: The detailing process begins with the collection of essential project information, such as architectural and engineering drawings, design specifications, and project scope. This information serves as the foundation for the detailing work.

- Detailing Software and Tools: Structural steel detailing is typically carried out using specialized computer-aided design (CAD) software such as AutoCAD, Tekla Structures, or Advance Steel. These tools allow detailers to create accurate 2D and 3D representations of the steel structures.

- Creating Drawings: Detailers create a variety of drawings, including:

- Erection Drawings: These provide guidance for the assembly and installation of steel components on the construction site. They include details on the placement of each steel piece, connection methods, and other critical information.

- Shop Drawings: These drawings are used by steel fabricators to manufacture the individual steel components. They include dimensions, material specifications, welding details, and more.

- Connection Details: Detailers illustrate how different steel components are connected, specifying the type of connections, welding details, bolts, and other fasteners.

- Material Specifications: Detailers specify the types of materials to be used, including the grade of steel, coatings, and other relevant information. This ensures that the final structure meets design and safety requirements.

- Dimensioning and Tolerances: Accurate dimensioning is crucial to ensure that the fabricated components fit together properly. Detailers apply industry-standard tolerances to accommodate variations in the manufacturing process.

- Clash Detection: 3D modeling software allows detailers to identify potential clashes or interferences between steel components, as well as with other building systems (e.g., mechanical, electrical, plumbing). This helps prevent construction issues.

- Bill of Materials (BOM): A detailed BOM lists all the steel components required for the project, including quantities, sizes, and specifications. This information is used for procurement and fabrication.

- Quality Control: Detailed drawings undergo thorough reviews to ensure accuracy and compliance with design specifications and industry standards.

- Collaboration: Detailers work closely with architects, engineers, contractors, and fabricators to address any design or construction challenges and to make necessary adjustments.

- Final Deliverables: The final deliverables include a comprehensive set of drawings, documents, and data files, which are used by fabricators, erectors, and construction teams to build the steel structure accurately and safely.

In the context of industries, such as manufacturing plants, oil and gas facilities, and industrial warehouses, structural steel detailing becomes even more critical due to the complex and heavy-duty nature of the structures involved. Proper detailing ensures that the industrial facility is safe, durable, and efficient in its operations.

Conclusion

Steel is a versatile element used in the construction of vast structures and buildings, both commercial and residential. However, structural detailing is essential to make the best use of steel components to erect structures. Structural steel detailing comes to your rescue here. It can be used for creating both erection and shop drawings. Moreover, CAD adds life to structural steel drawings with utmost accuracy and precision. Hence, structural steel detailing is the key to unlocking construction projects now.