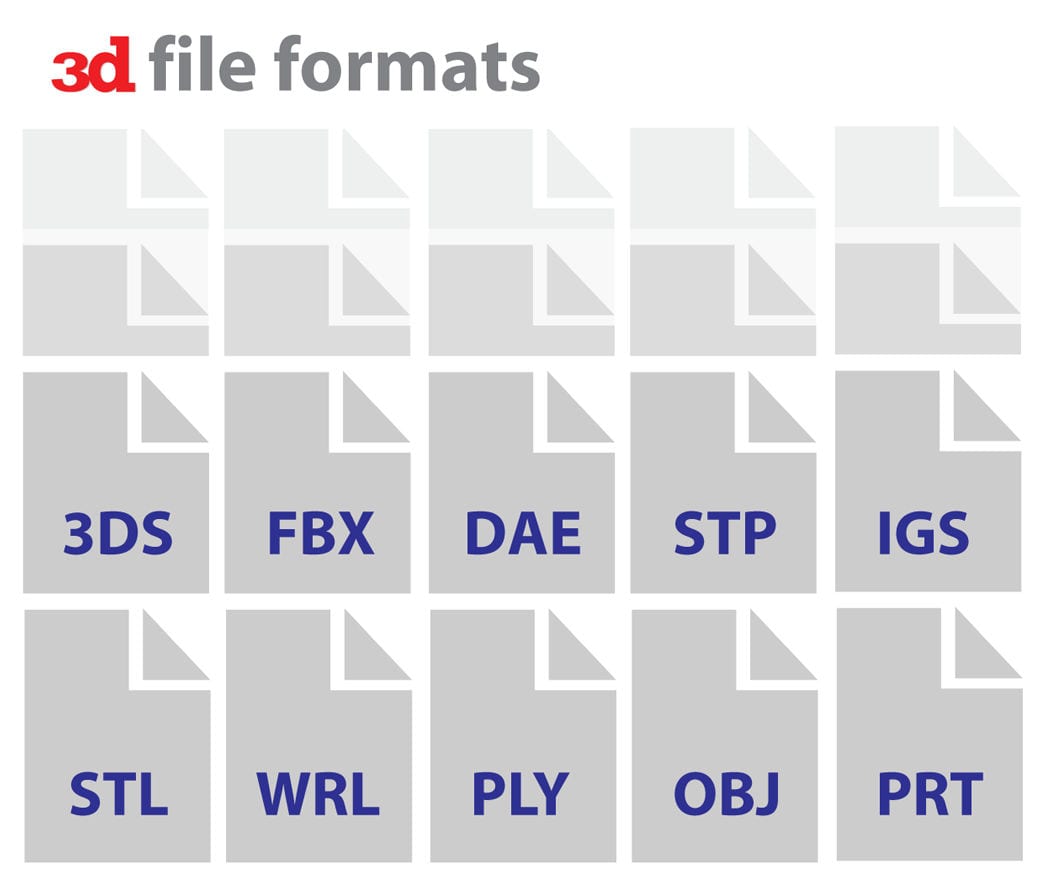

3D Scanning Digital Model Formats – The Many Flavors of 3D CAD.

We would like to take a little pause here and discuss things you can do with a CAD model. It led to questions like how to use the OBJ file and how it’s different from an STL? Can an IGES and a STEP file be used for the same thing? We call the “Flavours” of CAD that provide the shortlist to help clear some details.

VARIOUS CAD FLAVORS:

- DWG – This is a native AutoCAD drawing file

- ASCII (or ASC) – an X, Y, Z point cloud file in ASCII text format.

- IGES – “Initial Graphics Exchange Specification” – a neutral format for exchanging CAD data between many different software programs

- DXF – “Drawing Interchange File” – a neutral version of a DWG file

- OBJ – an open data format that represents the vertices of polygons

- SLDPRT – a native CAD format for SolidWorks

- PRT – a native CAD formatfor Pro/ENGINEER and NX

- STEP – “Standard for the Exchange of Product model data” (ISO 10303), an advanced neutral format for exchanging CAD data between many software programs.

- STL – “Standard Tessellation Language” – a polygonal model format similar to OBJ and several others

- WRL (VRML) – “Virtual Reality Modelling Language,” a polygonal file similar to OBJ, STL and several others and can include colour

- X_T – a semi-neutral CAD format

- Wikipedia maintains a list of CAD file formats that interest List of File Formats adding Computer-aided design.

NEUTRAL FORMATS:

- From the above 0..list, one can notice neutral CAD formats that come with specifically IGES and STEP formats. The two formats create a neutral exchange of 3D CAD data across different CAD packages.

- IGES created in 1979 along with the group of users, and it supports the Department of Defence (DoD) and NIST with exchanging data with ease. Since the late ’80s’80s, the DoD has offered Digital Project Manufacturing Data (PMI) with deliverables in IGES format.

- STEP offer ISO standard released in 1994 with becoming a “successor” to IGES. At the same time, using it with not replace the IGES format.

EXTRA FLAVORS:

While the above examples, it comes with the standard across CAD packages. It uses industries like Architecture. 3D modelling mainly uses computer graphics with their packages and file types. We like to think of these as extra flavours, like CAD dessert.

3D Graphics – 3D graphics formats generally work based on the package. Few popular graphics programs come with 3D +Studio Max, Lightwave and Maya. Few popular gaming companies, including Blizzard Entertainment and other film studios, often develop their in-house formats. However, many consumer 3D graphics packages can import OBJ files.

3D Scanning Digital Model Formats

3D Modelling for Architecture: It comes with a new modelling style for facilities, such as buildings and processing plants, which are developing rapidly. The CAD software contains a relational database component to store metadata for the design entities, such as the style and make of windows or doors or the schedule of the I-beams and piping. The new class of software called BIM mainly uses building information modelling to combine facilities management into the database concept.

By checking the above examples, it’s just a tiny taste that comes with the “flavours” of CAD. But they are the most common files used. Hopefully, this will help to get a better understanding. If you have any queries, ask for a 3D service provider and contact us at info@astcad.com.au.

What is the 3D Scanning Service?

3D scanning service is a process of capturing the physical shape and appearance of real-world objects or environments and converting them into digital 3D models. It involves using specialized hardware such as 3D scanners to collect data points from the surface of an object or a scene. These data points are then processed using software to generate a detailed 3D representation that can be manipulated, analyzed, or used for various applications.

The applications of 3D scanning services are diverse and span across industries such as manufacturing, engineering, architecture, healthcare, entertainment, and cultural heritage preservation. Some common uses include:

Reverse engineering: Creating digital models of existing physical objects for design modification, replication, or analysis.

Quality control: Inspecting manufactured parts for defects or deviations from specifications.

Digital archiving: Preserving historical artifacts, artworks, or archaeological findings in a digital format.

Virtual reality and augmented reality: Generating 3D assets for immersive experiences and simulations.

Customization: Tailoring products or services based on individual body scans or measurements.

Forensic analysis: Documenting crime scenes or accidents for investigation and reconstruction purposes.

What are the different types of 3D scanning?

There are several different types of 3D scanning technologies, each with its own advantages, limitations, and applications. Here are some of the main types:

Laser Triangulation (Active): This method involves projecting a laser onto the object being scanned and using a camera to capture the deformation of the laser line as it interacts with the surface. By triangulating the position of the laser points, a 3D model can be generated. It’s commonly used for high-precision scanning of small to medium-sized objects.

Structured Light (Active): Similar to laser triangulation, structured light scanning projects a pattern of light onto the object and uses cameras to capture how the pattern deforms on the surface. By analyzing these deformations, the scanner can determine the object’s shape and texture. It’s often used for capturing detailed surface textures and colors.

Time-of-Flight (Active): Time-of-flight scanners emit bursts of light and measure the time it takes for the light to return to the sensor, calculating the distance to each point on the surface. This method is effective for scanning large objects or environments and is commonly used in applications such as architectural scanning or topographic mapping.

Photogrammetry (Passive): Photogrammetry involves taking multiple photographs of an object or scene from different angles and using software to analyze the images and reconstruct the 3D geometry. It’s a versatile and cost-effective method that can be used with standard cameras, drones, or even smartphones. However, it requires good lighting conditions and may struggle with reflective or transparent surfaces.

Contact (Touch Probe): Contact scanning involves physically probing the surface of an object with a mechanical or electronic probe. The probe measures the position of points on the surface and sends the data to a computer for reconstruction. This method is highly accurate but may be slower and more invasive than non-contact methods.

X-ray and CT scanning: X-ray and computed tomography (CT) scanning are used for capturing the internal structure of objects, such as medical imaging or inspecting the integrity of manufactured parts. These methods are particularly useful for non-destructive testing and inspection.