It is no secret that managing Gigabytes of CAD data can be tough. Especially if you’re a new comer to a company that contains years of legacy data, you’ll probably be spending at least 2 hours a day on non-essential task, which is sorting out your files.

Solidworks Cad

What’s more, every department in a company (or dare I say every employee in a company), has their own way of sorting their files. Yes, a company may enforce a rule that any files checked into the server of the company follows a certain nomenclature, but who is going to enforce it?

Poor Data Management leads to many issues such as:

- Poor Decisions based on faulty or poor information

- Duplicated efforts because one users did not know that the work he is doing was already done by someone else and it was in the company’s data storage

- Lost of sales because customer’s cant get the information in time and leaves in frustration

- Lost of productivity as employees disturbs other employees for data that is already there but can’t find them

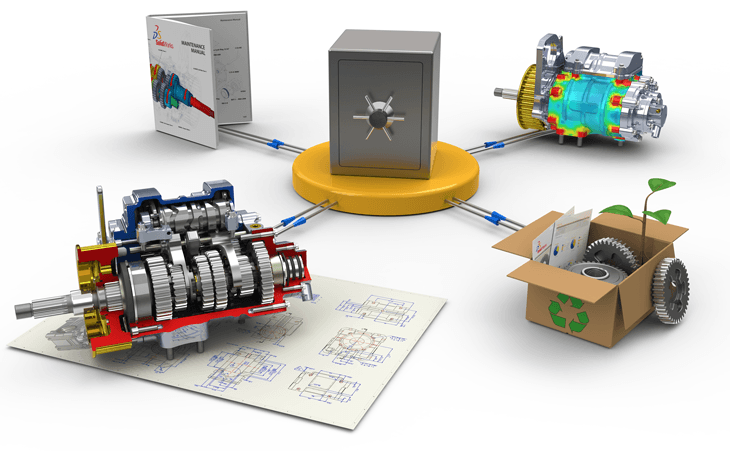

This is where a data management needs to be more than just a security center. It needs to be an intelligent vault. Introducing an intelligent PDM system, called SOLIDWORKS Product Data Management (PDM).

Nothing screams horror than sifting through an assembly with 1000s of parts just so that you pull it out replace with another. Another concern would also be to pinpoint where a particular standard part is used (Important if you need to replace a part thought to be standard with a revised version).

The default Microsoft search function may not be able to help you find you the parts you want as search function are based on how the OS indexes the files. With SOLIDWORKS PDM, all your CAD files are promptly indexed to make the search function more powerful and accurate. With the ability to give you where the files has been used and the history of the file, you can quickly and efficiently get the information you need!

If you are in an organisation whereby a few engineers work on a same project, you would most likely fall in the trap of working on a file in which someone else is working on at the same time. At the end of the day when it comes to putting it all together, nothing fits! Back to the drawing board….

Solidworks Cad Data Management

PDM controls the flow of all the documents, making sure each users knows the status of the file. If one person is working on a file, others may still view it, but not work on it until the initial user is done. Think of PDM as your friendly traffic police, making sure the flow of documents keeps moving without a hiccup.

Sometimes when a particular step goes idle, due to:

- Awaiting confirmation on the green light

- Awaiting confirmation that a correction is needed

- Awaiting for other departments to make a move

The user may also forget about his/her own movement in the project, and they are not aware of the status of the steps mentioned above.

With PDM, the process workflow defined in the PDM system keeps you updated about what steps are currently in progress and who is in charge. Built in is also the Notification Capability, which reminds the person-in-charge to keep the process going, so that no time is wasted!

The biggest concern about any data management solution is whether:

- Is it easy to manage?

- Do I need to hire an IT person to constantly look over it?

Be assured that the PDM solution will keep your data safe, organised and compliant.

One of the biggest roadblocks to adopting a data management systems is the fear that users may not get used to the system, which locks them out from the pool of data. Well that is not the case with PDM. With its tight integration with Windows, accessing files is as easy as using Windows explorer, opening folders to access the files. With its structured way of checking in/out of files, you will be assured that any files being opened or entered the vault is following company protocol.

It’s a step-by-step method which keeps all your files organised and populated with essential date.

File history is always difficult to track unless the right discipline is instilled in the user. By default, most users when it comes to editing an old file will just save the new version over it, completely destroying the older version of the file. What happens is that:

- Nobody knows what changes were made

- Nobody knows who made the changes

- And if the new version is not acceptable and need to revert back, its not possible! (Time wasted in recreating the old version)

So why not let PDM do that with you? It keeps track of the entire history of your files, AUTOMATICALLY! Let engineers do the designing, and PDM on the file management.

SOLIDWORKS Enterprise PDM includes:

> File management: centralised file vaulting capabilities to manage and control electronic intellectual property and product design data

> Revision management: track changes, maintain a complete revision history of a design’s evolution, and avoid the errors of manual approaches

> Bill of materials (BOM) management: a range of tools for making BOM information management more efficient, enabling you to export BOM data in multiple ways to use in downstream applications and systems

> Distributed collaboration: keep people connected, up to date, and working on the same set of data, regardless of their location

> Regulatory compliance: helps you comply with government regulatory requirements or industry standards for controlled development processes and product documentation

> Design reuse: create a framework for quickly locating and reusing or repurposing existing design data

> Engineering change management: significantly reduce the time needed to complete your design approval and engineering change order (ECO) processes with the automated electronic workflow system

> Secure file vaulting: securely control access to sensitive or proprietary product information

> Enterprise scalability: easily connect the design data needs of your entire enterprise, whether for just a few users in a single location or hundreds of contributors working in multiple locations around the world

If you would like to know more about PDM, CAD Data Management please feel free to contact us at +61 731 493 547 or email info@astcad.com.au, and our EPDM experts would be happy to help!

Australian Design & Drafting provides quality solidworks drafting service around Brisbane, Sydney, Melbourne, Perth, GoldCoast. We also provide affordable contract Solidworks drafter, Solidworks designer with short notice!..

What is CAD data management?

CAD data management refers to the process of organizing, storing, and controlling computer-aided design (CAD) files and related data throughout their lifecycle. This includes managing various types of CAD files, such as 2D drawings, 3D models, assemblies, and associated documents.

The goals of CAD data management typically include:

Organization: Ensuring that CAD files are stored in a logical and structured manner so that they can be easily located and accessed when needed.

Version Control: Tracking different versions of CAD files to avoid confusion and ensure that the latest version is always being used.

Access Control: Controlling who can access, view, edit, and delete CAD files to maintain data security and prevent unauthorized changes.

Collaboration: Facilitating collaboration among team members by providing tools for sharing CAD files, tracking changes, and managing concurrent design activities.

Data Integrity: Ensuring the accuracy, consistency, and completeness of CAD data throughout its lifecycle, including during creation, modification, and archiving.

Integration: Integrating CAD data management with other systems and processes, such as product lifecycle management (PLM), enterprise resource planning (ERP), and document management systems, to streamline workflows and improve efficiency.

What is solidworks product data management?

SolidWorks Product Data Management (PDM) is a software solution provided by Dassault Systèmes SolidWorks Corporation for managing SolidWorks CAD files and other related design data. It is designed to streamline the process of managing design and engineering data throughout its lifecycle, from initial creation to final production.

SolidWorks PDM offers a range of features and capabilities, including:

File Management: Organizing SolidWorks CAD files, assemblies, drawings, and other documents in a centralized repository, making it easy to locate, access, and share data.

Version Control: Tracking different versions of files and managing revisions to ensure that the correct and up-to-date versions are always being used.

Revision Control: Managing revisions to files, including assigning revision numbers, tracking changes, and maintaining a history of revisions for audit purposes.

Workflow Management: Defining and automating workflows for design processes, such as review and approval workflows, to ensure that tasks are completed efficiently and according to established procedures.

Access Control: Controlling access to files and data, including defining user permissions and access rights to ensure data security and prevent unauthorized changes.

Collaboration: Facilitating collaboration among team members by providing tools for sharing files, communicating feedback, and coordinating design activities.

Integration: Integrating with other SolidWorks products, such as SolidWorks CAD software, as well as with third-party applications and systems, to streamline data exchange and improve interoperability.