IGES and STEPFILES both are “neutral file formats”. They are compatible with using different 3D packages. The IGES (Initial Graphics Exchange Specification) is the oldest developed in the mid ’70s used to solve compatibility issues between different software packages. Let’s discuss about each of them in brief:

STEP (Standard for the Exchange of Product data) created in the ’80s and uses ISO as an improvement on IGES. It’s most widespread format in IGES and can contain basic 2D or 3D data. It is more versatile and contains additional data using material information and tolerances.

For most design engineers, the scenario looks familiar: Let’s say, Person 1, the lead designer of company X, require to send a CAD model to Person 2, the design engineer for company Y. Person 1 designed the part and Person 2 works in Pro Engineer. Person 1’s file can’t be opened in person 2’s software, therefore, it become simple to transfer a part file and become a problem.

The issue of non-interchangeable proprietary file formats for CAD data have work for decades. The software companies promote the use of modelling packages and ensure that only their package can open a file that created in their software. Unfortunately, all major 3D modelling software company can communicate between them is an issue.

Also, a solution exists in the form of neutral file formats where one canpass between different modelling software packages. One can use a neutral file format to pass CAD mode and then open it and work with it as required. The most common variants of all neutral file formats are the IGES and STEP formats. User recognise these formats by understanding the file name that ends with. iges, .igs, .stp, or .step.

THE HISTORY OF NEUTRAL FILE FORMATS

Talking about mid-seventies, the United States government realised that it had an issue. With using the unique proprietary CAD programs adds different contractors, millions of dollars and countless hours in it. They wasted the tedious process for sharing and converting data between all the systems. One can imagine how many times the scenario has played out on a large project such as an aircraft carrier or missile delivery system using hundreds of suppliers. Moving on with Air Force launched project in conjunction with Boeing.

There are large industry partners that create a neutral file format. The result was IGES (Initial Graphics Exchange Specification).It comes with flexible file format that can code drawing, 3d geometry, and add critical CAD data in a format can be shared between major CAD systems. The US Department of Defence require IGES format that is used for all weapons that has been adopted in other industries as well.

STEP (Standard for the Exchange of Product data) was created in the eighties along with an improvement on the IGES standard by ISO (the International Standards Organization). The goal creates global standard based on awide range of CAD-related data types. It adds complexity that undertake years of development and still continuously upgrade it. It offers largest ISO’s standards.

DIFFERENCE BETWEEN IGES AND STEPIGES uses widespread standard, that supports all major CAD systems worldwide.

An IGES file contains basic CAD information including 2D and 3D geometry such as surfaces, curves, and wireframes.

- It comes with presentation elements including drafting elements like lines and annotations.

- It offers electronic and pipe schematic elements along with finite element modelling.

- It comes with language and product definition data.

STEP comes with newer standard whereas IGES is not widespread. There are major CAD programs that is well-recognise as STEP and it’s steadily grown as their standard improves.

STEP documents contain the same product definition information as IGES, with the following additions such as Topology, Tolerances, Material properties and various other complex product data.

PRACTICAL CONSIDERATIONS

In several cases there are solid models or drawings shared with either file format that work fine. It comes with compatibility that is safest to start with IGES. It comes in most common format that is most likely to work by receiving party’s software. However, a designer considers the data to be shared with ease. If the file contains more product definition (for example, geometric dimensioning and tolerancing data, material properties, etc), then STEP would be a better choice.

It is not uncommon for supplier to trouble work with one format. Whereas it requests its alternative by depending on your software. It became familiar in most situations. We are the best Australian Design & Drafting Services company to provide excellent CAD conversions for IGES and STEP file to native file format. Contact Us to get more information.

What is the difference between IGES and STEP files?

IGES (Initial Graphics Exchange Specification) and STEP (Standard for the Exchange of Product model data) are both standard file formats used for exchanging 3D CAD (Computer-Aided Design) data between different CAD systems. Here are the main differences between them:

Format and Structure:

IGES: IGES files are based on a neutral file format that represents geometric data (such as points, curves, surfaces) and also includes information about the structure of the CAD model (such as hierarchy and assembly relationships).

STEP: STEP files are more comprehensive and structured compared to IGES. They can include geometric data, as well as product and manufacturing information (PMI), such as tolerances, annotations, materials, and other properties.

Complexity and Capability:

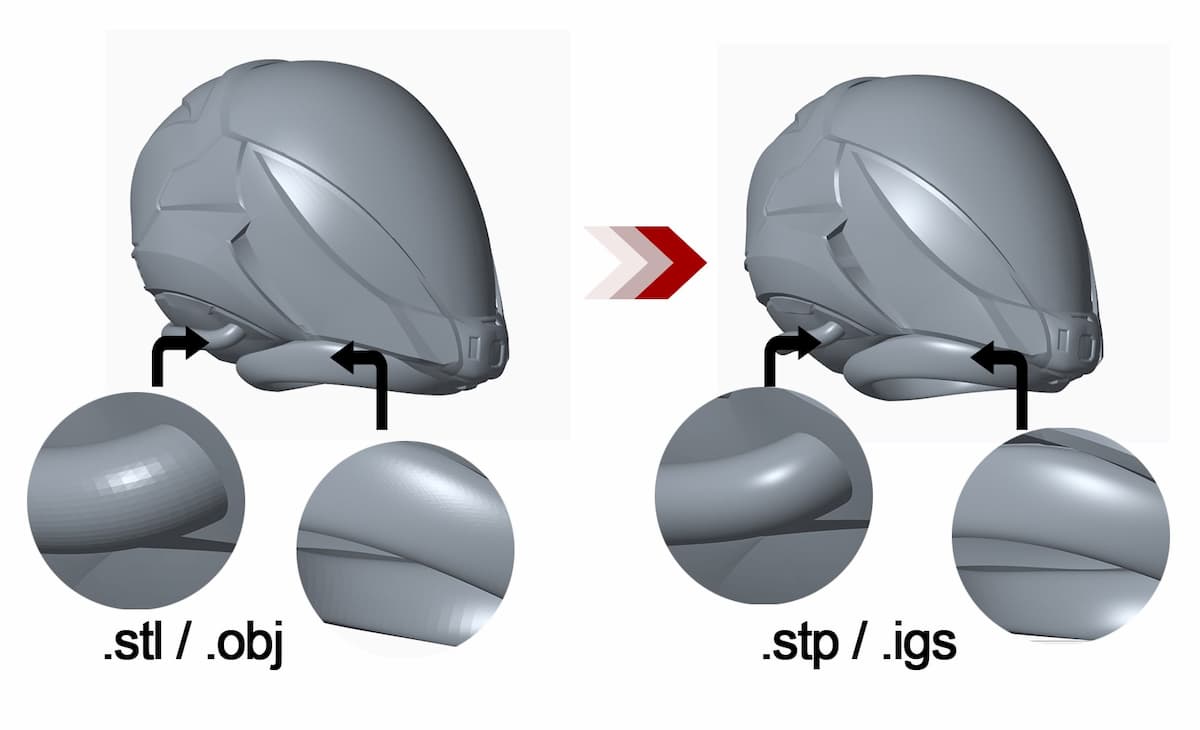

IGES: IGES is an older format and is less capable of representing complex CAD data compared to STEP. It may have limitations in representing certain types of geometry and features accurately.

STEP: STEP is a more modern and versatile format that can handle complex CAD data more effectively. It supports a wider range of geometric entities and features, making it suitable for more advanced CAD applications.

Industry Adoption:

IGES: IGES has been widely used since the 1980s and is still supported by many CAD systems. However, its usage has declined over time as STEP became more prevalent.

STEP: STEP has become the de facto standard for exchanging CAD data in many industries, including aerospace, automotive, and manufacturing. It is supported by most CAD software vendors and is preferred for its advanced capabilities and comprehensive data exchange.

File Size and Efficiency:

IGES: IGES files may be smaller in size compared to STEP files because they may not include as much metadata and detailed information.

STEP: STEP files can be larger in size due to the inclusion of additional information beyond just geometry. However, this additional information can be valuable for downstream processes such as manufacturing and simulation.

What is an IGES file?

An IGES (Initial Graphics Exchange Specification) file is a standard file format used for exchanging 3D CAD (Computer-Aided Design) data between different CAD systems. It was developed in the 1970s and has been widely used since then for interoperability between various CAD software packages.

IGES files are based on a neutral file format that represents geometric data, such as points, curves, surfaces, and solid models. Additionally, IGES files can also include information about the structure of the CAD model, such as hierarchy, assembly relationships, and basic attributes like colors and layers.

The purpose of IGES files is to facilitate the exchange of CAD data between different software systems without losing important geometric or structural information. This makes it easier for users to collaborate and share CAD models across different platforms.

However, it’s important to note that IGES is an older format and may have limitations in representing certain types of geometry and features accurately, especially compared to more modern formats like STEP (Standard for the Exchange of Product model data). Despite this, IGES remains in use, particularly in legacy systems and for simpler CAD models.