Structural steel detailing is an essential aspect of modern construction, offering precision and clarity that ensures a smooth transition from design to execution. With complex construction projects requiring detailed planning and coordination, structural steel detailing acts as a bridge between the architect’s vision and the on-ground execution. Let’s delve into how structural steel detailing enhances efficiency and accuracy in construction projects.

What is Structural Steel Detailing?

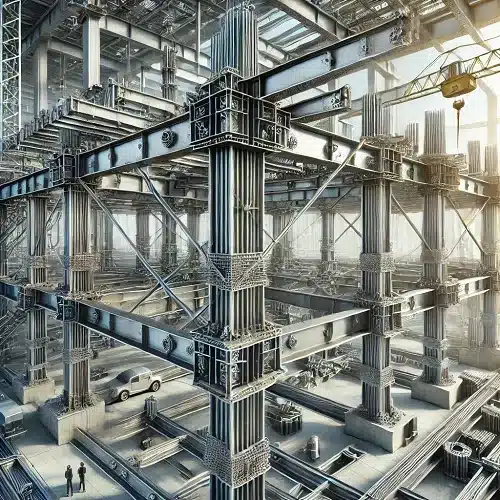

Structural steel detailing is a specialized discipline that involves the creation of detailed drawings and plans for the fabrication and erection of steel frameworks. These detailed blueprints include specifications such as dimensions, material grades, welding details, and connection methods. They provide a comprehensive guide for fabricators and contractors to assemble steel structures accurately.

The detailing process relies on advanced tools like CAD (Computer-Aided Design) software and BIM (Building Information Modeling) technology to produce precise 2D and 3D drawings. This ensures that all project stakeholders, including engineers, architects, and fabricators, are on the same page.

Key Ways Structural Steel Detailing Streamlines Construction Projects

1. Enhanced Precision in Design and Fabrication

One of the primary benefits of structural steel detailing is the accuracy it offers. Every detail, from the size of a bolt to the type of weld, is meticulously planned. This eliminates ambiguities, reduces errors, and ensures that components fit seamlessly during assembly.

For example, precise detailing minimizes the chances of rework or material wastage, saving both time and resources. Fabricators can rely on these detailed drawings to create components that meet exact specifications.

2. Improved Communication Among Stakeholders

Structural steel detailing serves as a common language for architects, engineers, contractors, and fabricators. The detailed drawings and plans ensure that everyone involved in the project understands the design intent and execution strategy.

This improved communication reduces the risk of misunderstandings and delays. When all stakeholders work from the same detailed plan, the construction process becomes smoother and more efficient.

3. Faster Project Turnaround

Time is a critical factor in construction projects. Structural steel detailing accelerates project timelines by ensuring that the fabrication and erection processes are well-organized. Fabricators can begin their work with confidence, knowing that the detailed drawings provide a clear roadmap.

Moreover, the use of advanced software in detailing allows for quick adjustments and updates to designs, keeping the project on track even when unexpected changes occur.

4. Enhanced Safety and Compliance

Structural steel detailing ensures that all components meet safety and compliance standards. Detailing professionals take into account load requirements, stress points, and material capabilities to design structures that are both safe and durable.

This level of attention to detail helps prevent structural failures and ensures compliance with local building codes and industry standards. By prioritizing safety during the detailing phase, the risks associated with construction projects are significantly reduced.

5. Cost Efficiency Through Reduced Errors

Errors in construction can lead to costly delays and rework. Structural steel detailing minimizes these risks by providing a detailed and accurate representation of the project. The early identification of potential issues, such as clashes or design inconsistencies, ensures they can be resolved before construction begins.

Additionally, precise material specifications and quantities help in accurate procurement, reducing wastage and unnecessary expenses. This cost-saving aspect is particularly valuable in large-scale construction projects.

6. Seamless Integration with Modern Technologies

Structural steel detailing integrates seamlessly with modern construction technologies like BIM and prefabrication. By creating 3D models, detailers can simulate the assembly process, identify clashes, and optimize the design for efficiency.

This technology-driven approach allows for prefabricated steel components to be delivered to the site ready for assembly, further reducing construction timelines and costs.

Applications of Structural Steel Detailing in Construction Projects

Structural steel detailing is used in a variety of construction projects, including:

- High-Rise Buildings: Ensures the stability and strength of complex steel frameworks.

- Bridges: Provides precise details for large-scale, load-bearing structures.

- Industrial Facilities: Supports the design of heavy-duty frameworks for machinery and equipment.

- Commercial Complexes: Facilitates aesthetically pleasing yet structurally sound designs.

Why Choose Professional Structural Steel Detailing Services?

Partnering with professional structural steel detailing services ensures access to skilled experts who understand the nuances of the process. These professionals utilize cutting-edge software to deliver high-quality, accurate drawings that streamline every phase of construction.

At ASTCAD, we specialize in providing top-notch structural steel detailing services tailored to meet the unique requirements of your projects. From complex industrial structures to intricate architectural designs, our team is equipped to handle it all with precision and efficiency.

Conclusion

Structural steel detailing is an indispensable tool in modern construction, ensuring precision, efficiency, and safety. By streamlining communication, reducing errors, and accelerating timelines, it helps construction professionals deliver projects on time and within budget.

If you’re looking to optimize your construction process, investing in professional structural steel detailing services is a step in the right direction. Contact ASTCAD today to learn more about how we can assist with your next project!