Autodesk Introduces Whisky Drinks for AutoCAD and CAD Drinks for Engineers – Helping Them Plot Their Own Cocktails. Now Autodesk users can download their own copy of CAD drinks, and learn to mix cocktails with precision.

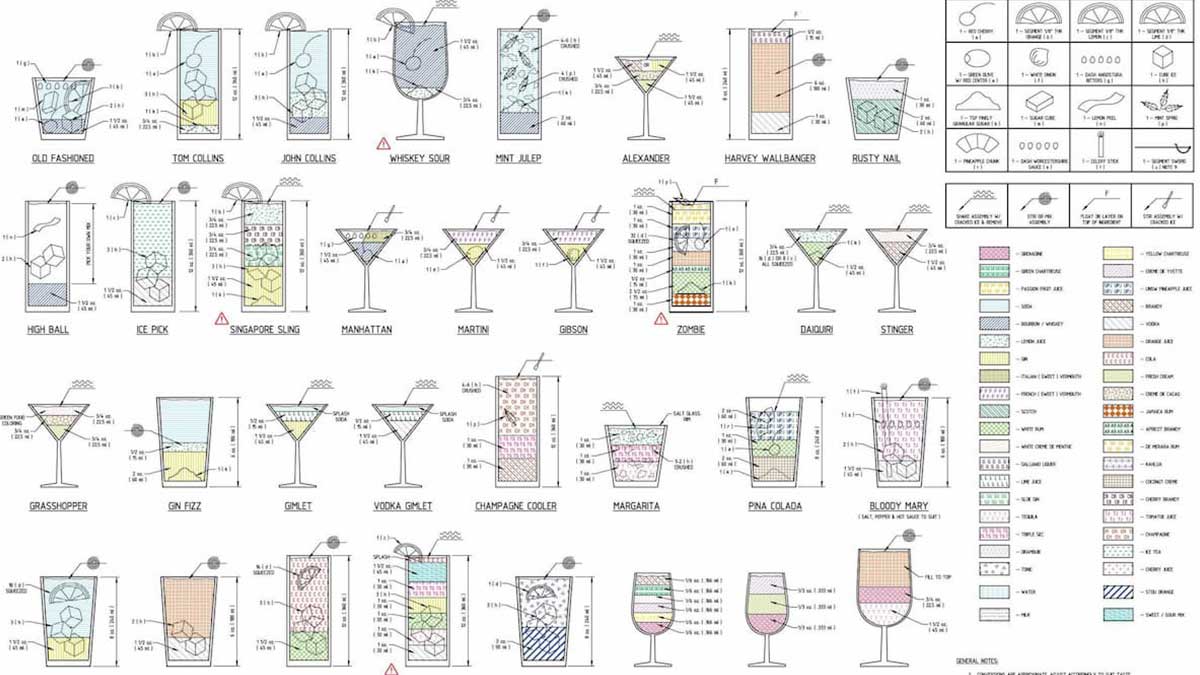

The DWG files contain all the information about the technique of mixing your drinks – simply by shaking them or by stirring with/without cracked ice. The schematics also suggest what glass to use, which ingredients go first and lists all the details of what to put in your glass and how, drawn right there – orange segment, pineapple chunk, onions, cherry, mint leaves, ice cubes, finely granulated sugar and the list goes on, all have a different recognizable graphics.

The drafts are drawn to scale in elevation, here alcoholic and non alcoholic drinks are color coded and rendered and the files are available in downloadable DWG file formats. The info graphics are prepared to appeal to an architect/ engineers brain and are replete with instructions for mixing and consumption of the drinks.

CAD drinks promises fun hour for architects and engineers as they meet after work, and design their cocktails just like they design buildings and machines. Designed by an engineer Shaan Herley, the chart codes more than 70 cocktails in their classic form right from the traditional Martini, to the popular Pina Colada.

Download Whiskey Drinks AutoCAD DWG File

Engineer’s CAD Drinks for industries

It seems like you are looking for information about CAD (Computer-Aided Design) software used in the context of designing drinks for industries. However, the concept of “CAD Drinks” might be a bit unclear. Let me try to provide some information based on the given context.

In the food and beverage industry, including the beverage industry, CAD software is commonly used for various purposes, such as designing packaging, manufacturing equipment, and even planning layout and workflow in processing plants. Here are some potential applications of CAD in the drink industry:

- Packaging Design: CAD software can be used to create 2D and 3D models of beverage containers, such as bottles, cans, and tetra packs. Engineers and designers can use these models to optimize the shape, size, and functionality of the packaging.

- Equipment Design: CAD is utilized to design machinery and equipment used in the production and processing of beverages. This includes components like mixers, pumps, conveyors, and filling machines. Designers can model and simulate these machines to ensure efficient and safe operation.

- Factory Layout: CAD software can assist in planning and designing the layout of a beverage manufacturing facility. Engineers can create detailed floor plans that optimize space usage and workflow efficiency.

- Process Simulation: CAD tools with additional capabilities for process simulation can help engineers evaluate and optimize the beverage production processes. This may include heat transfer simulations for pasteurization or CFD (Computational Fluid Dynamics) for mixing and flow analysis.

- Label and Branding Design: CAD software can be used to create label designs for beverage bottles or packaging. Designers can visualize and iterate on label designs before production.

- Quality Control and Testing: CAD can be used to create test fixtures and molds for quality control testing of beverage products.

It’s important to note that while CAD software is widely used in various industries, specific applications may vary depending on the unique requirements and processes of each industry and company.

Computer-Aided Design (CAD) has become an indispensable tool in the beverage industry, providing engineers, designers, and manufacturers with a wide range of applications to streamline and optimize their processes. From conceptualizing the initial design to final production, CAD software plays a vital role in enhancing product development, improving efficiency, and ensuring quality in the beverage manufacturing process.

One of the primary areas where CAD is extensively utilized is in packaging design. Engineers and designers can create intricate 3D models of beverage containers, exploring various shapes, sizes, and materials to find the most functional and visually appealing packaging solutions. These digital prototypes enable rapid iteration, cost-saving, and a reduction in material waste during the physical prototyping stage.

Moreover, CAD software aids in the development of machinery and equipment used in beverage production. Engineers can design complex processing equipment, such as blenders, filtration systems, and carbonation units, with precision and accuracy. By simulating the equipment’s performance in the CAD environment, potential issues can be identified and rectified before they become costly problems during actual production.

In large-scale beverage manufacturing plants, factory layout planning is critical for optimal workflow and resource management. CAD tools enable engineers to create comprehensive floor plans, visualizing the placement of machinery, production lines, storage areas, and employee workstations. This ensures that the plant’s layout maximizes space utilization and minimizes bottlenecks, leading to increased productivity and reduced downtime.

What type of engineers use CAD?

Several types of engineers use Computer-Aided Design (CAD) software in their work, including:

Mechanical Engineers: They use CAD to design mechanical systems, machinery, components, and products.

Civil Engineers: CAD helps them design infrastructure projects such as roads, bridges, dams, and buildings.

Electrical Engineers: CAD is used in the design of electrical systems, circuits, and components.

Aerospace Engineers: CAD is vital for designing aircraft, spacecraft, and related components.

Architectural Engineers: CAD assists in designing architectural structures, including buildings and interior spaces.

Automotive Engineers: CAD is used extensively in designing vehicles, their components, and systems.

Environmental Engineers: CAD aids in designing environmental systems and solutions, such as wastewater treatment plants and pollution control devices.

CAD software allows engineers from various disciplines to create detailed digital models of their designs, facilitating visualization, analysis, and collaboration throughout the design process.

Do engineering students use CAD?

Yes, engineering students often use CAD software as part of their academic curriculum. Many engineering programs include courses specifically dedicated to teaching CAD skills. These courses aim to familiarize students with CAD software and its applications in their respective fields of study.

Using CAD software allows engineering students to:

Gain practical skills: CAD software is widely used in industry, so learning it during their studies prepares students for their future careers.

Visualize concepts: CAD enables students to create digital models of engineering designs, helping them visualize complex concepts and understand how different components interact.

Design projects: Engineering students often have design projects as part of their coursework, and CAD software provides them with the tools to create detailed and accurate designs.

Collaborate with peers: CAD software allows students to collaborate with their classmates on group projects by sharing digital models and working on them together.