Are you planning to take a dive into the construction industry? If yes, and you are an artist, the structural steel shop industry can be the best fit for you. Structural steel shop drawings are in high demand in the construction market and play a crucial role in constructing steel structures.

However, making a well-organized structural steel shop drawing can be daunting. So, we have given you a guide to structural steel shop drawings to help you develop the best one.

Understand structural steel shop drawings

Purpose: Structural steel shop drawings form a roadmap for contractors, erectors, and fabricators. It acts as a guide towards appropriate dimensions, connections, and specifications of the steel components to be employed in the building or the structure.

Hence, the purpose of structural steel shop drawings is to communicate strongly between the design team and the fabrication or erection team. Else how, who would give life to your design into physical steel components.

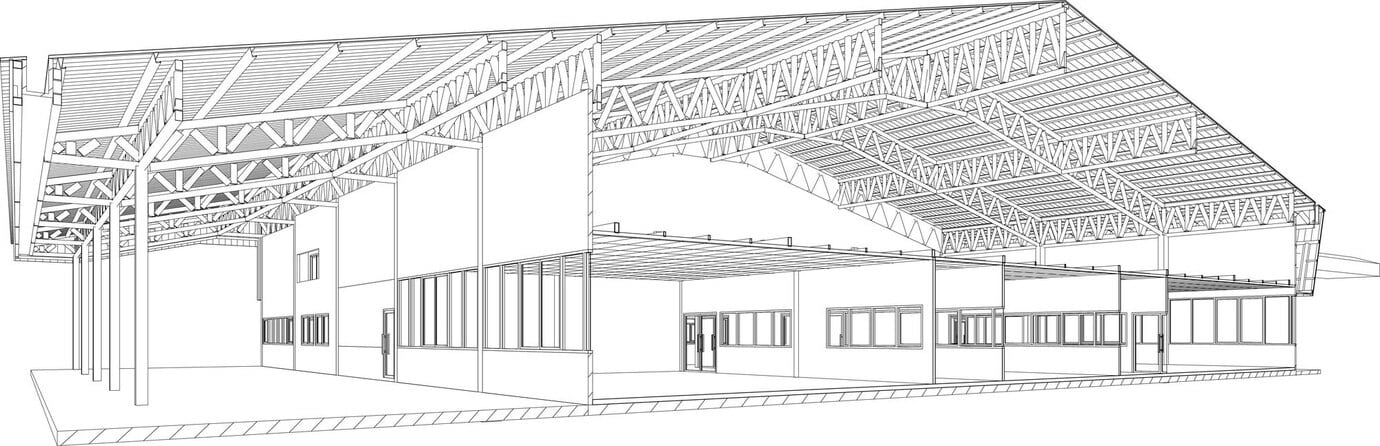

Components: You must know the basic components used in the construction industry to inculcate them in your drawings. Beams, columns, trusses, braces, connections, anchor belts, etc., are essential components of structural steel shop drawings.

Standards and codes: Abiding by the regulations and standards set by the construction industry is an important factor, and it must reflect in the structural steel shop drawings.

The standards are set keeping in mind the integrity of the structures. Hence, you must know the local building codes and industry compliances before approaching your drawing.

Key elements in structural steel shop drawings

Now that you know what purpose a structural steel shop drawing serves, you must equip yourself with the key elements to be included.

General notes: Adding general notes to structural steel shop drawings facilitates communication between the design and the construction team. It conveys important information about the project, materials, fabrication, quality standards, and other special instructions, thus forming a key element in structural steel shop drawings.

Elevation and section views give your steel shop drawings a structural view. Elevation and section views show the relationships and connections between the vertical and horizontal arrangement of the steel components.

Plan views: Besides the horizontal and vertical arrangement of steel structures, your drawings must have a plan view. It refers to how various steel elements are located, including their sizes and dimensions.

Details and connections: Now comes the part where you connect different steel structure elements to ensure proper assembly. Different details showing connections between the steel components are bolts, welds, and fasteners.

Bill of materials: Last but not least, you must include the bill of materials associated with your structural steel shop drawings. It assists the resource management team in providing the constructors with the right quantity of materials with the proper size and specifications, thus streamlining the overall project.

Creating structural steel shop drawings

It is time to finally get your hands dirty and create structural steel shop drawings. However, there are some points you must keep in mind to come up with a structural steel shop drawing that serves the purpose well.

Collaboration: Remember that you can not create a structural steel shop drawing alone. A healthy collaboration with other teams of the construction project is essential. Hence, you must ensure you are on the same page with the design team, including the fabricators and erectors.

Design intent interpretation: Your drawings must convey the design intent to other departments. This includes the fabricators and erectors, as they will implement the design.

Coordinating with other trades: Coordinating with other trades is as important as collaborating with the construction team. It must be planned considering other trades, such as mechanical, plumbing, electrical, etc. This helps you avoid clashes and integrate the plan swiftly.

Accuracy and detail: Paying attention to details is familiar; you must implement them in your structural steel shop drawings. It ensures the accuracy and precision of your drawings, incorporating the tolerances, measurements, and clear labelling of various components.

Reviewing structural steel shop drawings

Once you finish your drawing, you must review it before you let it out. You must verify several factors to ensure the structural steel shop drawing maintains the integrity of structures and buildings.

Compliance: When your structural steel shop drawing is ready with all your dedication and effort, you want it to be safe from being thrown in the trash for not complying with the legal standards. Hence, reviewing your drawing and checking if it abides by all the specifications, codes, and standards is always best.

Constructability: Your structural drawings are only useful if they can be implemented practically. Hence, you must review it for constructability, considering the factors such as access, sequencing, and practicality during fabrication and erection.

Coordination: As mentioned in the previous section, coordination with other trades is necessary. So, if there are any clashes or interferences, they should be addressed to maintain the integrity of the structure.

Accuracy and completeness: Lastly, ensuring your structural steel shop drawing is complete, accurate, and in proper flow with the other project requirements is necessary.

Structural steel shop drawings are detailed drawings prepared by structural steel fabricators based on the structural design drawings provided by the structural engineer. These drawings provide specific information about the fabrication and installation of steel components in a construction project. Here are some key points about structural steel shop drawings:

- Purpose: The main purpose of structural steel shop drawings is to provide precise details and instructions to the fabricators regarding the production of steel elements, such as beams, columns, trusses, connections, and other components. These drawings act as a roadmap for fabricators to ensure accurate manufacturing and assembly.

- Content: Shop drawings typically include a range of information, such as dimensions, material specifications, member sizes, welding details, connection types, bolt sizes, and other relevant data. They may also include assembly instructions, erection sequencing, and any additional requirements specific to the project.

- Compliance: Structural steel shop drawings must comply with the design intent of the structural engineer’s drawings, applicable codes and standards, and any project-specific requirements. They are reviewed and approved by the engineer or other relevant stakeholders to ensure accuracy and adherence to the design.

- Coordination: Shop drawings facilitate coordination between different trades involved in the construction project. They provide valuable information to architects, engineers, contractors, and other stakeholders, enabling them to visualize the steel elements and plan their work accordingly. Shop drawings also help identify clashes or conflicts with other building components, allowing for timely resolutions.

- Fabrication Process: Fabricators use the shop drawings to procure the necessary steel materials, cut and shape the components, assemble them, and prepare them for delivery to the construction site. The drawings act as a guide throughout the fabrication process, ensuring that the finished products align with the design intent.

- Detailing Software: Structural steel shop drawings are typically created using specialized computer-aided design (CAD) software, such as AutoCAD or Tekla Structures. These software tools allow for precise modeling of steel components, generation of detailed drawings, and the creation of accurate bills of materials.

It’s important to note that the responsibility for the accuracy and completeness of shop drawings lies with the fabricator, while the structural engineer remains responsible for the overall design and structural integrity of the project. Effective communication and collaboration between the engineer, fabricator, and other project stakeholders are crucial for the successful production and installation of structural steel components.

Conclusion

Structural steel shop drawings act as the bible for construction projects, containing all essential elements to ensure proper fabrication and erection of the steel structures. However, there are many factors you must consider while making a steel shop drawing to give rise to a grand structure with a streamlined project. Hence, you can follow this guide on a great creative journey.

What are structural steel shop drawings?

Structural steel shop drawings are detailed drawings created by steel fabricators or drafters to guide the fabrication and installation of structural steel components in construction projects. These drawings provide precise information about the dimensions, shapes, materials, and connections of each steel element, such as beams, columns, braces, and trusses.

Key components typically included in structural steel shop drawings are:

Elevation Drawings: Show the front, side, or end views of the steel members, indicating their size, shape, and location.

Plan Drawings: Provide a top-down view of the steel structure, detailing the layout of beams, columns, and other elements.

Detail Drawings: Focus on specific connections, joints, or other intricate parts of the steel structure, providing detailed information for fabrication and installation.

Material Lists: Include lists of materials needed for fabrication, such as types and sizes of steel sections, bolts, welds, and other components.

Dimensional Information: Precisely specify dimensions, tolerances, and other important measurements to ensure proper fit and alignment during fabrication and construction.

Welding Symbols: Indicate the location, type, and size of welds required to join steel members together.

What is steel structure drawing?

A steel structure drawing is a detailed technical illustration or diagram that depicts the design and specifications of a steel structure. These drawings are typically created by architects, structural engineers, or draftsmen and serve as a blueprint for constructing steel buildings, bridges, towers, or other structures.

Steel structure drawings include various elements such as:

Overall Layout: This provides an overview of the entire structure, showing its dimensions, placement, and orientation.

Foundation Details: These drawings depict the foundation design, including the type of foundation, its dimensions, reinforcement details, and connection points with the steel structure.

Framework: The framework drawings show the arrangement and configuration of steel beams, columns, braces, and other structural elements. This includes details such as member sizes, connections, and welding specifications.

Connections: Detailed drawings of connections between structural members, including welds, bolts, or other fastening methods, are crucial to ensure the stability and strength of the structure.

Stairs, Platforms, and Accesses: If applicable, drawings for stairs, platforms, ladders, and other access components are included to facilitate movement within the structure.

Material Specifications: Specifications for the type and grade of steel, as well as any other materials used in the structure, are often included in these drawings.

Loads and Forces: Information about the expected loads, forces, and stresses that the structure will need to withstand is also documented, guiding the design and construction process.