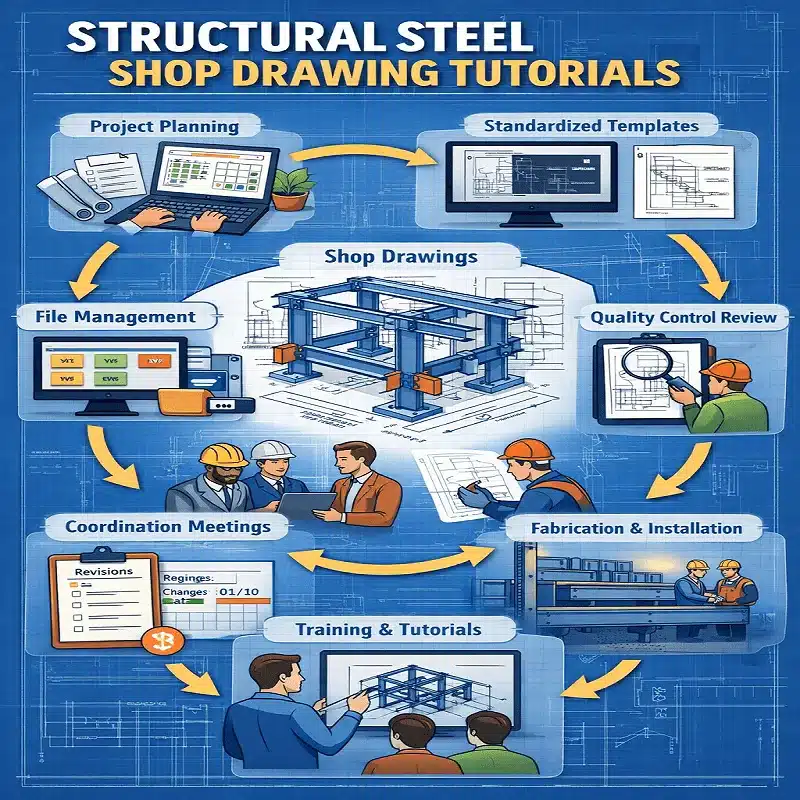

Structural steel shop drawings are essential in the construction and fabrication process. They serve as a bridge between design and construction, ensuring that structural components are accurately fabricated and installed. However, managing these projects efficiently can be challenging due to the complexity and volume of information involved. Proper organization not only saves time but also reduces errors, improves communication, and ensures project deadlines are met. In this blog, we will explore practical tips for organizing structural steel shop drawing projects efficiently, with a focus on STRUCTURAL STEEL SHOP DRAWING Tutorials for beginners and professionals alike.

1. Understand the Project Scope

Before starting a structural steel shop drawing project, it’s crucial to have a clear understanding of the project scope. This includes reviewing architectural and structural plans, specifications, and client requirements. Understanding the type of steel components, connections, and materials used will help you plan the drawing process more effectively.

Using STRUCTURAL STEEL SHOP DRAWING Tutorials, beginners can learn how to break down complex structural plans into manageable segments, making the project less overwhelming and more systematic.

2. Develop a Project Plan

A well-structured project plan is the foundation of efficient project organization. Start by creating a detailed timeline that includes milestones such as initial drafts, client reviews, and final approvals. Assign responsibilities to team members, especially in larger projects, to ensure each segment of the project is covered.

Project management software can be extremely helpful. Tools like Autodesk BIM 360, Procore, or even Excel sheets can track progress, deadlines, and revisions effectively. STRUCTURAL STEEL SHOP DRAWING Tutorials often recommend creating a checklist for each stage of the project, ensuring no step is missed.

3. Standardize Drawing Templates and Formats

Consistency is key when dealing with multiple shop drawings. Using standardized templates for title blocks, scales, and symbols ensures clarity and reduces the likelihood of errors. Standardized templates make it easier for team members to understand and follow drawings, even if they join the project midway.

Many STRUCTURAL STEEL SHOP DRAWING Tutorials emphasize the importance of using CAD standards for line types, layer names, and dimension styles. This not only streamlines the workflow but also facilitates smoother collaboration between designers, engineers, and fabricators.

4. Organize Digital Files Systematically

With the increasing reliance on digital tools, organizing your CAD files is as important as the drawings themselves. Maintain a clear folder structure, separating drawings by type, stage, or project segment. Include version control in file names to avoid confusion over revisions.

For example:

- ProjectName_DrawingType_V1.dwg

- ProjectName_DrawingType_V2.dwg

This ensures everyone on the team is working on the latest version. Many STRUCTURAL STEEL SHOP DRAWING Tutorials provide guidance on setting up efficient file management systems that reduce duplication and save time during revisions.

5. Prioritize Communication and Collaboration

Efficient structural steel shop drawing projects rely heavily on communication. Regular meetings, progress updates, and feedback sessions help identify issues early and prevent costly mistakes. Use cloud-based platforms to share drawings and comments in real time, which keeps all stakeholders informed.

Collaborating closely with fabricators is essential. Sometimes, minor adjustments in drawings can lead to significant cost savings and faster fabrication. Tutorials on STRUCTURAL STEEL SHOP DRAWING often stress the importance of clear communication channels between designers, engineers, and fabricators.

6. Review and Quality Check

Even with a well-organized system, errors can occur. Implement a thorough review process for all shop drawings before submission. This should include cross-checking dimensions, materials, connection details, and notes against project specifications.

Using a peer review system, where another engineer or designer verifies the drawings, can catch mistakes that might be overlooked. Many STRUCTURAL STEEL SHOP DRAWING Tutorials recommend a step-by-step review checklist to maintain quality and consistency.

7. Keep Track of Revisions

Revisions are a natural part of structural steel shop drawing projects. It’s crucial to maintain a revision log that records all changes, who made them, and when. This ensures accountability and makes it easier to trace back decisions if discrepancies arise.

Proper tracking of revisions also allows for accurate updates to fabrication and installation teams, preventing costly delays or rework. Tutorials in STRUCTURAL STEEL SHOP DRAWING often highlight the importance of maintaining detailed revision histories for efficient project management.

8. Implement Training and Continuous Learning

Structural steel detailing and shop drawing standards evolve over time. Invest in training your team with the latest STRUCTURAL STEEL SHOP DRAWING Tutorials, workshops, and software updates. Continuous learning helps improve efficiency, reduces errors, and ensures the team is aware of industry best practices.

Conclusion

Organizing structural steel shop drawing projects efficiently requires a combination of planning, standardization, digital organization, communication, and quality control. By following these tips and leveraging STRUCTURAL STEEL SHOP DRAWING Tutorials, both beginners and experienced professionals can streamline their workflow, reduce errors, and ensure timely project completion. Investing time in proper organization not only improves productivity but also ensures the successful execution of steel fabrication projects.

FAQ

What are structural steel shop drawings?

Structural steel shop drawings are detailed, fabricated-ready drawings showing the dimensions, materials, and assembly instructions for steel components. They are used by fabricators and construction teams to ensure accurate fabrication and installation.

Why is organizing shop drawings important?

Efficient organization reduces errors, saves time, ensures consistency, improves communication, and facilitates smoother project management.

How can beginners learn structural steel shop drawing efficiently?

Beginners can follow STRUCTURAL STEEL SHOP DRAWING Tutorials, which provide step-by-step guidance, templates, and examples to help understand best practices and workflows.

What software is commonly used for structural steel shop drawings?

Popular software includes AutoCAD, Tekla Structures, Revit, and SolidWorks. These tools allow precise detailing, modeling, and collaboration.

How should revisions be tracked?

Maintain a revision log detailing the version, date, changes made, and responsible team member. Use standardized file naming conventions for clarity.