WHAT ARE THE DIFFERENT CADD FORMATS

CADD FORMATS

There are several different CADD formats. The most recognized CADD formats include 2D drawings and 3D wireframe, surface, and solid models. In general, 2-D drawings and 3-D solid models are the most common CADD formats currently used in the industry. Three-dimensional surface models are also widely used, but often for specific applications. Three-dimensional wireframe models are rare in the current industry. Software specifies the CADD format, which usually focuses on a certain process such as 2-D drawing or 3-D solid modeling.

However, some systems offer tools for working in a variety of formats or the ability to use drawing or model content created in a different format. For example, you can often develop a 2D drawing from 3D model geometry or build a 3-D solid model from 3-D surface model geometry. A software add-on or separate application is sometimes required to work with multiple CADD formats.

Beyond the Basics: A Granular Look at CADD Formats

While the article rightly mentions 2D drawings and 3D models (wireframe, surface, solid) as the primary CADD formats, let’s delve deeper into their characteristics:

- 2D Drawings: The workhorse of many industries, 2D drawings offer a familiar and efficient way to represent designs. They excel in:

- Manufacturing & Construction: Standard format for conveying precise dimensions and details.

- Simple Designs: Ideal for quick projects that don’t require significant revisions.

- Annotation & Communication: Effective for adding notes, dimensions, and other project-critical information.

- 3D Wireframe Models: These skeletal representations depict designs using lines and curves to connect points in 3D space. While less common today, they can be useful for:

- Conceptualization & Early Design Stages: Providing a basic framework for visualizing initial design ideas.

- Rapid Prototyping: Laying the groundwork for creating physical models.

- 3D Surface Models: A step up from wireframes, these models capture a design’s outer “skin” using mathematically defined surfaces. They find application in:

- Organic Shapes & Complex Geometry: Representing curved and freeform elements effectively.

- Visualization & Aesthetics: Creating realistic renderings for presentations or marketing purposes.

- 3D Solid Models: The crown jewel of CADD formats, solid models represent a design as a complete, volumetric entity. This allows for:

- Advanced Analysis & Simulation: Performing stress analysis, calculating weight and volume, and simulating real-world behavior.

- Detailed Design & Manufacturing: Creating highly accurate models for downstream processes like CNC machining or 3D printing.

- Collaboration & Assembly: Facilitating seamless integration of different design components.

Understanding these distinctions empowers you to choose the right format for the job.

CHOOSING A CADD FORMAT

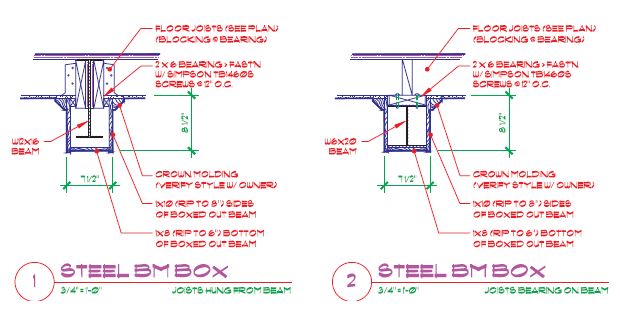

Several factors influence CADD software and format selection. Design and drafting practices and specific project requirements are primary considerations. Two-dimensional drawings are often required because they are the standard format in manufacturing and construction.

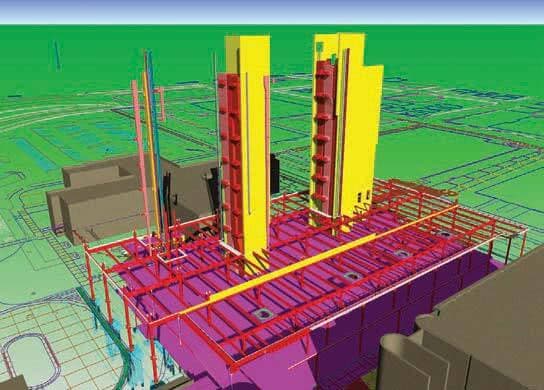

The figure shows a 2-D structural detail required for building construction. In addition, 2-D drawing is effective for a project that is quick to design, does not require extensive revision, and does not require advanced visualization, simulation, and analysis. Three-dimensional solid modelling is a better solution when a complex project requires extensive revision and when advanced visualization, simulation, and analysis are required. A 3-D representation of a design can help overcome visualization problems and produce a realistic, testable product model.

The figure shows a multidiscipline 3D model of a building providing structural, electrical, HVAC, and piping layouts. A combination of CADD formats and software may prove most effective for a project when applied correctly. Bringing the advantages of each CADD format together maximizes product design flexibility and effectiveness.

Collaboration and communication during a project also influence CADD software and format selection. Everyone involved in a project must be able to use a common CADD format or be able to convert data to a usable format easily. Costs are another important factor to consider when choosing a CADD software and format. For example, advanced 3-D solid modelling software is generally more expensive than 2-D drafting software. Operating a new or different CADD system also requires training and time to learn. Training is an expense and takes time from projects that produce income. A more capable CAD format, such as 3D solid modeling, is extremely cost-effective for some users, especially over time, but others will never benefit from the initial costs of the software and training. Several additional factors also influence selecting CADD software and format, including choosing a product and a format that is a known industry standard for project requirements, software stability and usability, the availability and effectiveness of support and training, and personal preference.

Beyond the List: Advanced CADD Format Considerations

The realm of CADD formats extends beyond the basic types mentioned earlier. Here’s a glimpse into some specialized options:

- Neutral Formats (DXF, STEP): These formats allow data exchange between different CAD software programs, promoting interoperability.

- Point Cloud Data: Captured from 3D scanners, point clouds represent objects as a collection of data points, providing a highly detailed representation of physical objects that can be integrated into CAD models.

- Additive Manufacturing Formats (STL, AMF): Used for 3D printing, these formats translate CAD models into a format compatible with 3D printers for physical fabrication.

Understanding these advanced formats expands your design toolbox, allowing you to leverage the power of CADD for a wider range of applications.

Conclusion

CADD formats are more than just file extensions; they are the building blocks of your design workflow. By understanding their nuances and selecting the right format for your project needs, you can optimize your design process, enhance collaboration, and ultimately achieve superior design outcomes.

Australian Design & Drafting Services provides excellent service for CAD Design and Drafting. Contact Us for more info.