TWO-DIMENSIONAL (2D) DRAWINGS

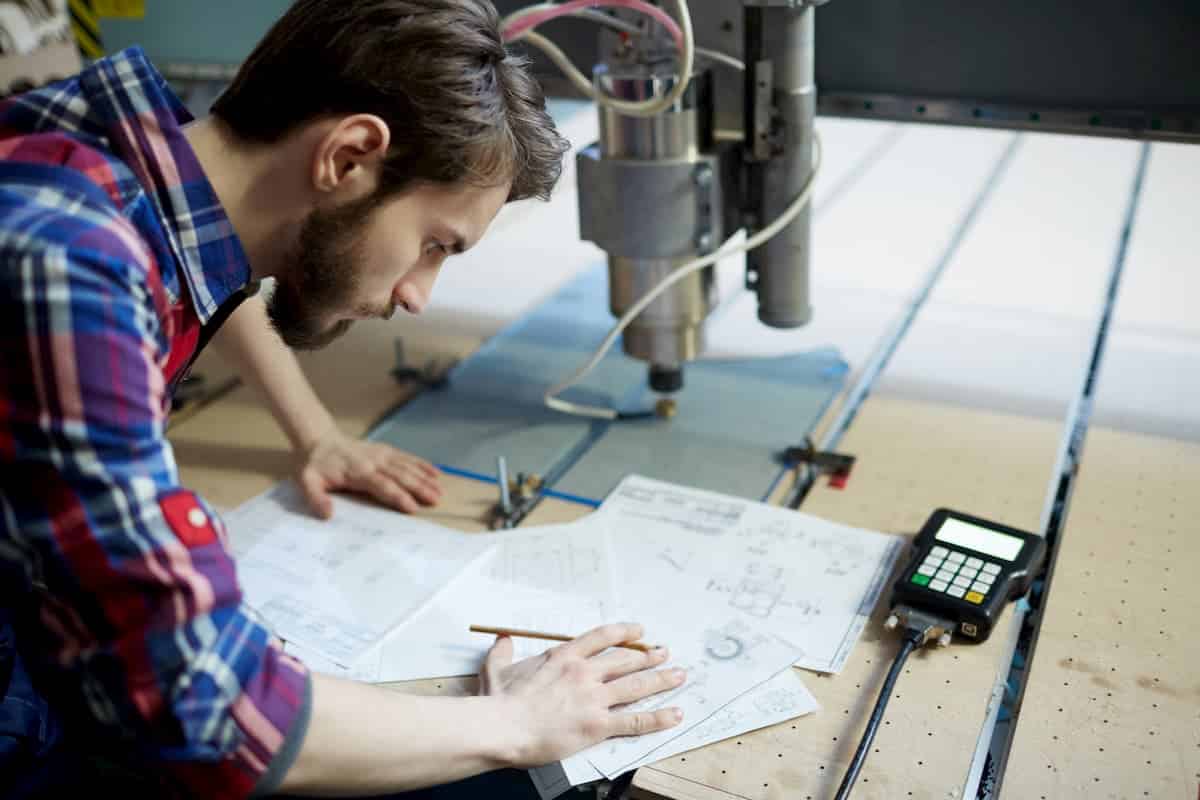

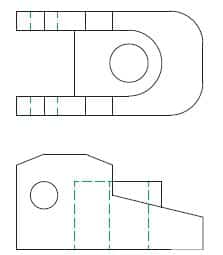

2D & 3D Drawings – The abbreviation for two-dimensional drawing is 2-D. It describes the view that comes with using height, width and length. Or it can be length and length dimensions. It comes with two-dimensional drawings that are established using design and drafting format. They commonly used for all engineering and architectural industries that relates to the disciplines with ease.

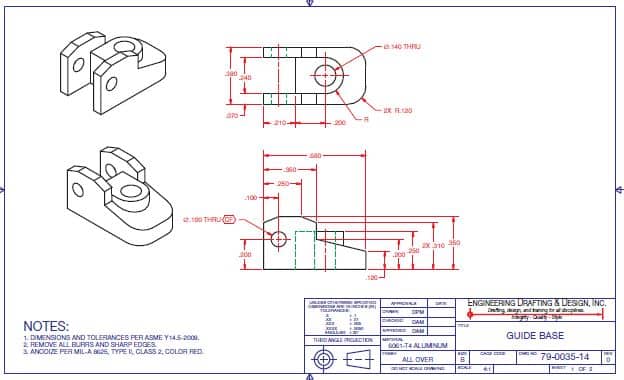

The two 2-D views represent the geometry of an aircraft part. It uses two views that come together and provide height, width, and length dimensions. The views mostly appear in the flat format and are rotated at 90 degrees from each other.

It comes with a complete 2-D drawing that include notes, dimensions, and text that describes view details and features. 2D drawings are the conventional and need to use method for communicating a project. Along with this, it uses an effective 2-D drawing accurately with describing design intent and product requirements. It covers the shape, size, and characteristics of all materials, features, finishes, and manufacturing methods.

A 2D drawing comes with typical documents that add project data for individuals and companies that are involved in the project. It covers relevant dates, design and approvals based on revision history. The 2D drawings offer computer numerical control (CNC) machine code. When compared with 3D surface and solid models, 2D drawings use few options to present and visualise the ideas. and limited ability to analyze and test product design. In addition, 2D drawings sometimes can be difficult to understand, if the reader is unfamiliar with interpreting 2D drawings.

THREE-DIMENSIONAL (3D) DRAWINGS

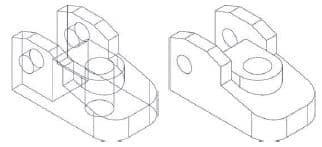

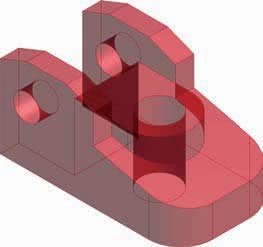

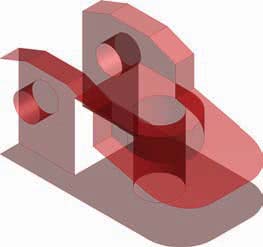

The abbreviation for three-dimensional is 3-D. It describes an object that have a height, a width, and depth dimensions. A wire-frame model offers the most basic 3-D CAD model, and contains data about object vertices and edges. The word vertices are plural when used for vertex. It points the edges that intersect. The wireframe is a term that describe the appearance of the model if they are constructed using wires.

Talking about three-dimensional surface, then it’s used as solid modelling placed in wireframe modelling in the CAD industry. The wireframe models come with a limited models use because they lack mass and surfaces. Without using the surfaces, the wireframe models are most difficult to visualise. It comes with creating an uncertain design intent. It does not require a true representation of a product, and lack volume.

Difference Between 2D 3D Drawings

Few tools come with an ability to change or hide the format of the lines fall through object features. It improves visualisation and create a 3-D representation way, along with a view for a 2-D drawing. However, the display can cause confusion. Especially when user view the complex objects. Without using the mass or the volume, the wireframe models come with a limited ability to analyse and test products.

Difference Between 2D 3D Drawings

A wireframe model comes with a small file size that offer fast display regeneration, store edge and vertex data. Whereas, the Wireframe models serve as a basis to construct 3-D surface and solid models. It provides the geometry for 2-D drawings. One can rotate and repurposing a wireframe model by producing the 2-D views. The Wireframe models uses 3D CNC machine code with ease.

THREE-DIMENSIONAL (3D) SURFACE MODELS

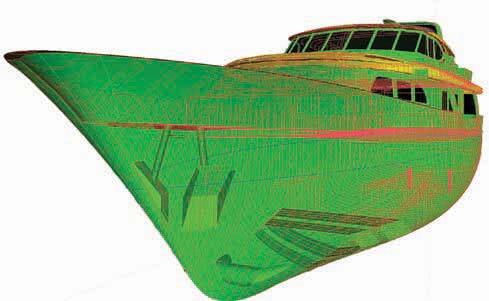

A surface model use data about object vertices, edges, and surfaces. It comes with an outer boundary object that connects to vertices and edges. The surfaces display shade, color, reflection, and texture that helps to improve visualisation. Surfaces reduce uncertainty about design intent and offer a true representation of a product. Surface modelling provides the ability to create complex curves and forms.

3D surface modelling is commonly used for CAD industry, particularly used for conceptual design and industrial design to construct certain shapes. A surface model has zero thickness, lacks mass, and do not enclose a volume. The Surface models allow uses basic calculations that includes surface area and volume, but without mass. It comes with limited ability to analyse and test physical and inertial properties. With time the most common users of surface models are designers that primarily concerned with the external shape and appearance of a product.

The hull design is a common application for surface modelling. The automobile body panel is another example of a product that needs to have an accurate surface. It covers animations, video games, virtual reality programs, and other programs that use similar requirements to form complex surfaces, especially when solids are unnecessary and file size is generally smaller than solid model files.

Surface models serve as a basis to construct 3-D solid models, and provide the geometry for 2-D drawings. It can rotate and repurpose a surface model to produce the 2-D views and display realistic surfaces on the 3-D representation.

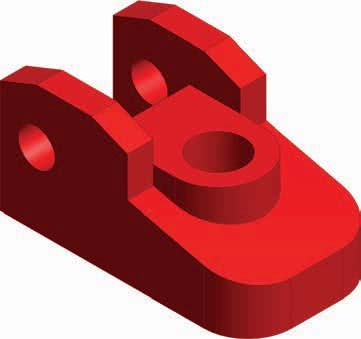

THREE-DIMENSIONAL (3D) SOLID MODELS

3A solid model is one of the most complex CAD formats that contains data about object edges, vertices, surfaces, and mass. Talking about Solid models, it’s most common 3-D CAD format used in the current CAD industry. It encloses a volume and has mass that allows designers and engineers to analyze the exterior and interior object characteristics. In contrast to a 2-D drawing, it offers a note that specifies the material assigned to a product.

2D and 3D Drawings

It comes with using 3-D surface model that displays a representation of material on surfaces. It assigns material to a solid model for analysing and testing physical and inertial properties. As a result, a solid model acts as a digital prototype of a product. It provides the geometry for 2-D drawings. We are best Australian Design & Drafting Services company to offer excellent CAD Design and Drafting. Contact Us to clear your doubts.

What is 2D drawing and 3D drawing?

2D drawing and 3D drawing are two different methods used to represent objects or scenes in visual art, design, and engineering.

2D Drawing:

In 2D drawing, objects are represented using only two dimensions: length and width. These drawings are typically created on a flat surface, such as a piece of paper or a computer screen.

Examples of 2D drawing include sketches, blueprints, floor plans, and technical drawings.

2D drawings are often used in fields such as graphic design, architecture, engineering, and illustration.

They provide a simple and clear representation of objects but lack the depth and perspective that 3D drawings offer.

3D Drawing:

In 3D drawing, objects are represented using three dimensions: length, width, and height. These drawings create the illusion of depth and perspective, making objects appear more realistic.

3D drawings are created using specialized software or by sculpting physical models.

Examples of 3D drawing include computer-generated imagery (CGI), architectural renderings, product designs, and character animations.

3D drawings are widely used in industries such as animation, video games, film production, industrial design, and virtual reality.

They allow for more detailed and immersive representations of objects, making them ideal for visualization and simulation purposes.

What is 2D vs 3D diagram?

A 2D diagram represents objects or concepts in two dimensions, typically on a flat surface such as a piece of paper or a computer screen. It uses length and width to depict objects, but lacks depth. Examples of 2D diagrams include floor plans, maps, blueprints, and graphs.

On the other hand, a 3D diagram represents objects or concepts in three dimensions, incorporating length, width, and height. It provides a more realistic depiction of objects by adding depth, making them appear more lifelike and tangible. Examples of 3D diagrams include architectural renderings, computer-generated models, and medical imaging scans like MRI or CT scans.

In summary, while both 2D and 3D diagrams serve to visually represent information, 2D diagrams are limited to two dimensions, while 3D diagrams add depth to create a more immersive and realistic representation.