Computer-Aided Design (CAD) plays a crucial role in the design, development, and construction of industrial structures. CAD technology revolutionizes the traditional design process by enabling engineers, architects, and designers to create detailed and accurate digital representations of industrial structures. Here are some key aspects of CAD’s role in industrial structures:

The Role of Computer-Aided Design (CAD) in Industrial Structures

- Efficient Design Process: CAD software allows for the creation of detailed and intricate design elements quickly and accurately. Engineers can easily experiment with different design options, test various configurations, and make modifications without having to start from scratch, which significantly speeds up the design process.

- Precision and Accuracy: CAD tools enable precise measurements and accurate modeling, ensuring that every component of an industrial structure fits together seamlessly. This level of accuracy helps prevent design errors, clashes, and discrepancies that could arise during construction.

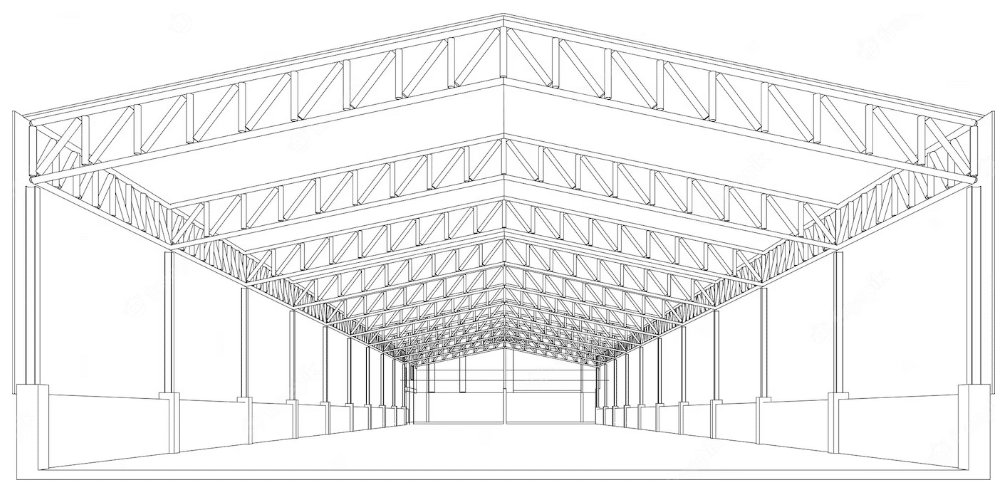

- Visualization and Communication: CAD provides realistic 3D visualizations and renderings of industrial structures. This helps stakeholders, including clients, architects, engineers, and construction teams, better understand the design intent, resulting in improved communication and reduced misunderstandings.

- Collaboration: CAD facilitates collaboration among various professionals involved in the design and construction process. Multiple team members can work on the same project simultaneously, sharing information and updates in real-time, which leads to more efficient teamwork.

- Simulations and Analysis: CAD software can simulate real-world conditions and perform structural, thermal, and fluid dynamics analyses. Engineers can evaluate how the industrial structure will behave under different loads, stress factors, and environmental conditions, ensuring its safety and functionality.

- Cost and Time Savings: Through CAD, designers can identify potential design flaws and issues before construction begins, reducing the likelihood of costly revisions and changes during the construction phase. This leads to significant time and cost savings in the long run.

- Documentation and Record-Keeping: CAD systems generate comprehensive documentation, including detailed drawings, specifications, and material lists. This documentation is essential for obtaining permits, approvals, and compliance with regulations.

- Adaptation and Iteration: CAD models can be easily modified and updated as the design evolves or new requirements emerge. This flexibility allows for iterative design processes and adaptation to changing project needs.

- Integration with Manufacturing: CAD models can be seamlessly integrated with computer-aided manufacturing (CAM) systems. This integration enables the efficient creation of prototypes and facilitates the transition from design to manufacturing.

- Legacy and Maintenance Support: CAD models serve as a digital record of the industrial structure’s design, making it easier to plan for maintenance, renovations, and modifications in the future.

In summary, CAD technology plays an indispensable role in the design and construction of industrial structures, offering benefits such as efficiency, accuracy, collaboration, visualization, and cost savings. Its integration into the industrial design process has transformed how professionals conceptualize, develop, and bring these structures to life.

Advantage of Industrial Structures

Industrial structures offer several advantages that contribute to the functioning and success of various industries. These advantages are a result of careful design, construction, and planning to meet specific industrial needs. Here are some key advantages of industrial structures:

Functional Space Utilization: Industrial structures are designed with a focus on maximizing usable space for manufacturing, storage, and other industrial activities. Efficient layout design helps optimize workflows, reduce material handling distances, and enhance overall operational efficiency.

Customization: Industrial structures can be tailored to meet specific industry requirements, whether it’s a factory, warehouse, power plant, or distribution center. Customization ensures that the facility’s layout, equipment, and infrastructure align with the production processes and operational needs.

Durability and Strength: Industrial structures are built to withstand heavy loads, harsh environmental conditions, and industrial operations. The use of durable materials and engineering expertise ensures that these structures can endure the rigors of industrial activities over an extended lifespan.

Safety and Compliance: Industrial structures adhere to stringent safety standards and regulations to ensure the well-being of workers, protection of assets, and compliance with industry-specific guidelines. This focus on safety minimizes accidents and hazards in the workplace.

Cost Efficiency: Well-designed industrial structures incorporate cost-saving measures through efficient use of materials, energy-efficient systems, and optimized layouts. Over time, these cost efficiencies contribute to improved profitability for businesses.

Scalability: Many industrial structures are designed with scalability in mind. As businesses grow and expand their operations, these structures can often be modified or expanded to accommodate increased production capacity or changing operational needs.

Technological Integration: Industrial structures are increasingly incorporating advanced technologies such as automation, robotics, and IoT (Internet of Things). These technologies enhance operational efficiency, reduce labor costs, and improve overall productivity.

Location and Accessibility: The strategic location of industrial structures near suppliers, transportation hubs, and target markets can reduce logistical challenges and transportation costs. Easy accessibility helps streamline supply chain operations.

Environmental Sustainability: Modern industrial structures are designed with environmental considerations in mind. Energy-efficient designs, renewable energy integration, waste reduction, and sustainable construction practices contribute to a reduced environmental footprint.

Aesthetic Considerations: While functionality is paramount, industrial structures are also designed with aesthetics in mind. An appealing and well-designed industrial facility can positively impact a company’s image, brand perception, and even employee morale.

Adaptability: Industrial structures can often be repurposed or adapted for different uses if business needs change. This adaptability can extend the useful life of a facility and provide flexibility for evolving industries.

Job Creation: The construction and operation of industrial structures contribute to job creation within local communities. These facilities require a diverse range of skilled professionals, from architects and engineers to maintenance staff and production workers.

What is industrial structure?

Industrial structure refers to the composition and organization of industries within an economy. It encompasses the types of industries present, their relative sizes, interconnections, and patterns of competition. Factors such as the number of firms, their market share, the degree of concentration, and the level of diversification all contribute to defining the industrial structure of an economy.

Key aspects of industrial structure include:

Industry Composition: The types of industries present in an economy, such as manufacturing, services, agriculture, etc.

Market Concentration: The extent to which a small number of firms dominate a particular industry or market segment. This can be measured by metrics like market share, concentration ratio, or the Herfindahl-Hirschman Index (HHI).

Degree of Competition: Whether industries are characterized by perfect competition, monopolistic competition, oligopoly, or monopoly. This affects pricing behavior, innovation, and efficiency within industries.

Vertical and Horizontal Integration: The extent to which firms within an industry are vertically integrated (controlling different stages of production) or horizontally integrated (consolidating similar stages of production).

Globalization and Trade: The level of international integration of industries, including the extent of imports, exports, and foreign direct investment.

Technological Dynamics: The role of technology in shaping industry structure, including innovation, automation, and digitalization.

Why are industrial structures important?

Industrial structures play a crucial role in the economy and society for several reasons:

Economic Growth: Industrial structures house factories and facilities where goods are manufactured and processed. These activities drive economic growth by creating jobs, generating income, and producing goods for domestic consumption and export.

Innovation and Technology: Industrial structures often serve as hubs for innovation and technological advancement. Research and development facilities located within these structures work on improving processes, developing new products, and advancing technology, which contributes to overall progress and competitiveness.

Infrastructure Development: Industrial structures are often part of larger industrial parks or zones, which require significant infrastructure development such as roads, utilities, and transportation networks. These investments improve connectivity and accessibility, benefiting both the industrial sector and surrounding communities.

Supply Chain Management: Industrial structures play a crucial role in supply chain management by providing storage and distribution facilities. They serve as logistical nodes where goods are stored, sorted, and transported, facilitating the movement of products from manufacturers to consumers.

Employment Opportunities: Industrial structures create employment opportunities, ranging from skilled manufacturing jobs to administrative positions. They provide livelihoods for workers and support families and communities.

Resource Utilization: Industrial structures enable the efficient utilization of resources by bringing together raw materials, labor, and capital in one location. This concentration allows for economies of scale and specialization, leading to increased productivity and efficiency.

Diversification of Economy: Industrial structures contribute to the diversification of the economy by supporting a wide range of industries, including manufacturing, energy production, transportation, and logistics. This diversity helps reduce dependence on any single sector and enhances resilience to economic shocks.

Environmental Impact: While historically industrial structures have been associated with pollution and environmental degradation, modern industrial practices increasingly focus on sustainability and eco-friendliness. Industrial structures can incorporate green technologies and practices to minimize their environmental footprint and promote sustainable development.