reverse engineering using pro-e-modeling scanning techniques

Innovation is our strength

CASE STUDY – Mechanical Engineering Design and Drafting Services

REVERSE ENGINEERING USING Pro-E-Modeling & Scanning TECHNIQUES

Engineering Design & Drafting | CAE Services: CFD & FEA | Reverse Engineering | Rapid Prototyping | Product Design | Value Engineering | PLM Services | Technical Documentation

Case Study Highlights

REVERSE ENGINEERING USING Pro-E-Modeling & Scanning

TECHNIQUES

The Client

- Industry: Automotive Parts Manufacturer

- Location: Australia

The Objective:

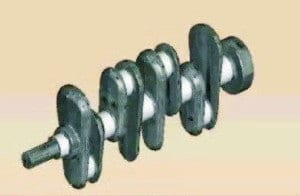

- Reverse engineer the crankshaft and identify the accurate dimensions needed for manufacturing.

The Solution:

- The point cloud data captured was converted into polylines & this data was then imported to Pro/E. With the data, a Pro/E model was created, which was used to carry out further analysis of the design & create production-ready drawings once the necessary modifications were carried out.

The Challenges:

- The client was facing the challenge of providing a crankshaft to one of its clients, for which the inventory had been exhausted & no more production was carried out by the OEM.

- The original design of the crankshaft was not available.

- To complete the engine assembly, the original design of the crankshaft was reproduced using reverse engineering techniques.

Reverse engineering benefits in obtaining useful design information about components becoming obsolete and having little information available to re-manufacture. It is a vital tool to study the component design in layers of information and identify the effort required to recreate the same.

A leading auto parts manufacturer in Australia needed to reverse engineer the crankshaft, which was designed to be utilized in vintage cars. Due to the unavailability of design information, manufacturing the crankshaft required suitable production-ready drawings.

The Solution:

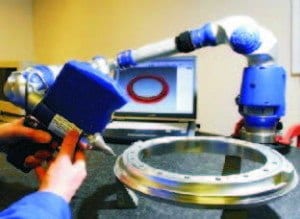

- The problem was dealt with by Australian Design and Drafting Services’s three-step process of Reverse Engineering: Data digitisation Integration-3D CAD Modeling. To accurately reproduce the design of the crankshaft, all the dimensions were first digitized using manual laser scanning & CMM measurement techniques.

Benefits:

- The Reverse Engineering techniques using CAD/CAM enabled the client to accurately recreate the design of the required part for which inventory had been exhausted.

- This technique augmented the production process by producing production-ready drawings.

- Certain design modifications as per the requirement could be made to make the design more robust.

About Australian Design And Drafting Services

Australian Design and Drafting Services is a specialist firm providing engineering solutions to organizations across the globe. We have extensive experience in providing concept to manufacturing and post-manufacturing solutions to clients with a team of expert design engineers, CAD professionals and simulation analysts. We are based in Australia, serving 24×6, with a world-class infrastructure, hardware and software capabilities to address complex engineering problems with the least turnaround time.