Converting Raw Point Clouds into CAD Formats

You’ve read your overview, figured out how to collect data, and now that you have this data, what do you do with it?

As you learned in Chapter Two, Direct Dimensions breaks data collection into two common methods: Laser Scanning and Digitizing. We also categorize the processing of the collected data into two main categories: Digital Modeling and Reverse Engineering. In this chapter, we’ll tell you what you need to know about Digital Modeling.

Digital Modeling: the process of creating a computer model of an object that exactly replicates the form of the object. Laser scanners are used to capture the 3D data of the object, and this data is transferred to the computer where it is aligned, edited and finalized as a complete 3D model.

Polygonal Models and Dumb Solids

So, when does something fall into the category of Digital Modeling as opposed to Reverse Engineering? At DDI it generally depends on a couple of factors: shape (organic vs. geometric) and desired file output. As a general rule of thumb, organic shapes tend to fall into the Digital Modeling category, as do polygonal models (STL Files) and Rapid NURBS Dumb Solids.

A Polygonal Model is a faceted (or tessellated) model consisting of many triangles. Facets are formed by connecting points within the point cloud. STL files can be used for visualization, rapid prototyping, design, milling, and analysis software.

A Rapid NURBS ‘Dumb’ Solid (usually in IGS format) starts with the polygonal model. NURBS surfaces are wrapped over the polygonal wireframe. This wrapped surface model is smoother than a polygonal model. The NURBS model can be brought into parametric modellers such as SolidWorks (albeit with no parametric history – which is why we call it dumb).

The bridge between Digital Modeling and Reverse Engineering is the hybrid Model. A Hybrid model is a polygonal model that has been converted in a rapid NURBS surface model and then also uses traditional solid modelling techniques. It is commonly used when basic geometric features, such as holes & edges, blend with complex organic contours, such as a machined casting.

Do Reverse Engineering and Digital Modeling ever Overlap?

In addition to Hybrid Models, there are instances when it is appropriate to use both Digital Modeling and Reverse Engineering techniques. For example, when collecting data of a large object (such as a plane) for Reverse Engineering, it is necessary to use a laser scanner to capture the massive amounts of surface data. The data output from a laser scanner is a point cloud, but point clouds cannot be brought into any CAD packages. Before the data can be transferred into CAD it must be digitally modelled into either a polygonal model or a Rapid NURBS dumb solid.

The Digital Modeling Advantage

There can be a fine line between Digital Modeling and Reverse Engineering and sometimes both methods can be a valid solution to 3D problems. Some advantages of Digital Modeling are:

- Digital Modeling generally offers a faster and more cost-effective solution.

- It presents a great solution for creating solid models when an object has organic contours.

- Offers excellent dimensional accuracy and can be utilized for comparative analysis.

- While it is true that Rapid NURBS Dumb Solid models do not have parametric history, they can be utilized as a base for design work and Boolean functions are possible.

- Unlike raw point clouds, Digital Models can be visualized in rendering software as a solid object, which is great for seeing the overall shape and contour of the model.

Getting Started

In Chapter Two we discussed data collection and various brands of scanners and digitizers that we use on a daily basis. Don’t worry! We won’t leave you hanging on what software packages we recommend for digital modelling. We use the following packages every day at DDI (in alphabetical order):

- Geomagic Shape Studio: Polygonal and NURBS modelling and point cloud to CAD comparison. Geomagic can automatically generate an accurate digital model from any physical part.

- PolyWorks Modeler: Polygonal modelling and point cloud to CAD comparison. PolyWorks can process large point clouds over 100 million points and easily integrates with all standard digitizers and articulating arms.

- Rapidform: Third generation point processing software for creating native parametric “design-intent” CAD models directly from scan data. At Direct Dimensions, we often use Rapidform in Hybrid Modeling but it also has a great Rapid NURBS function.

Tackling Reverse Engineering

Now that you know a bit more about what we call Digital Modeling and why it can be a great option, you are ready to tackle Reverse Engineering in next post.

Engineering and digital modeling play crucial roles in various industries, ranging from architecture and construction to product design and manufacturing. Here’s some information on these topics:

Engineering: Engineering is the application of scientific and mathematical principles to design, develop, and analyze structures, machines, systems, and processes. It encompasses several disciplines, including civil, mechanical, electrical, chemical, and aerospace engineering, among others. Engineers utilize their expertise to solve complex problems and create innovative solutions.

Key areas within engineering include:

- Structural Engineering: Focuses on the design and analysis of structures to ensure they are safe, durable, and capable of withstanding loads and environmental conditions.

- Mechanical Engineering: Involves the design and development of mechanical systems and devices, such as engines, machines, and tools.

- Electrical Engineering: Deals with the study and application of electricity, electronics, and electromagnetism. It includes areas such as power generation and distribution, electronics, and telecommunications.

- Chemical Engineering: Concerned with the design and operation of chemical processes, including the production of chemicals, pharmaceuticals, fuels, and materials.

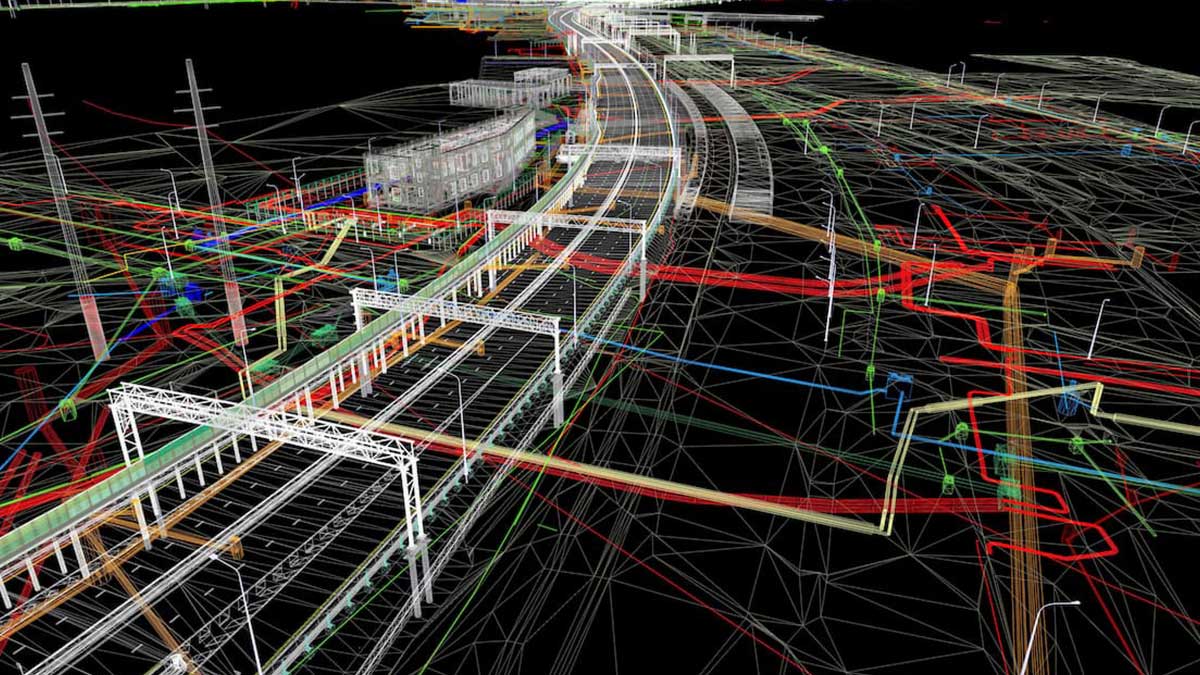

Digital Modeling: Digital modeling refers to the creation of virtual 3D representations of physical objects, structures, or systems using computer software. It enables engineers, designers, and architects to visualize and simulate their concepts before moving to physical production, thus saving time and resources. Some key aspects of digital modeling include:

- Computer-Aided Design (CAD): CAD software allows engineers and designers to create precise 2D and 3D models of products or structures. It offers tools for modeling, simulation, analysis, and documentation.

- Finite Element Analysis (FEA): FEA is a numerical technique used to analyze the behavior of structures or systems under various conditions. It helps engineers assess factors like stress, strain, and deformation to ensure the design’s integrity.

- Computational Fluid Dynamics (CFD): CFD is a simulation technique used to analyze fluid flow and heat transfer. It finds applications in areas such as aerodynamics, HVAC system design, and fluid flow optimization.

- Building Information Modeling (BIM): BIM is a collaborative approach to digital modeling specifically used in architecture, engineering, and construction. It integrates various aspects of a building project, including design, construction, and operation, into a centralized digital model.

Digital modeling tools enable engineers to iterate designs, detect potential issues, and optimize performance without physical prototyping. They enhance productivity, facilitate communication between team members, and support data-driven decision-making throughout the engineering process.

Contact Australian Design & Drafting Services for more information..

What is the digital modeling?

Digital modeling refers to the process of creating virtual representations of physical objects or systems using computer software. It is commonly used across various industries such as architecture, engineering, product design, animation, and video game development. Digital models can range from simple 2D sketches to complex 3D simulations.

In digital modeling, designers or artists use specialized software tools to construct, manipulate, and visualize digital representations of real-world objects or abstract concepts. These models can be highly detailed and accurate, allowing designers to explore different designs, simulate behaviors, and test various scenarios before committing to physical prototypes or production.

Digital modeling often involves techniques such as:

3D Modeling: Creating three-dimensional representations of objects or scenes. This can involve modeling individual components, sculpting shapes, or using procedural techniques to generate complex geometry.

Rendering: Generating realistic images or animations of digital models by simulating lighting, materials, and textures. Rendering can help visualize how a design will appear in different environments or under various conditions.

Simulation: Using digital models to simulate physical behaviors such as motion, stress, fluid dynamics, or electromagnetic interactions. This allows designers to analyze the performance of their designs and identify potential issues or optimizations.

Animation: Bringing digital models to life through movement and interaction. Animation techniques can be used for entertainment purposes, visualization of processes, or demonstration of concepts.

Virtual Reality (VR) and Augmented Reality (AR): Integrating digital models into immersive virtual or augmented environments. This enables users to interact with and experience digital content in a more immersive and engaging way.

What is meant by digital fabrication?

Digital fabrication refers to the process of using computer-controlled machinery and software to create physical objects from digital designs. It encompasses various technologies such as 3D printing, CNC (Computer Numerical Control) machining, laser cutting, and robotic assembly.

In digital fabrication, the design of an object is typically created using computer-aided design (CAD) software, which allows precise control over the dimensions, shapes, and other parameters of the object. This digital design is then translated into instructions for the fabrication equipment, which follows them to construct the physical object layer by layer, cut out shapes from materials, or perform other necessary actions.

Digital fabrication enables the rapid prototyping of designs, customization of products, and efficient manufacturing processes, as it eliminates many of the traditional constraints associated with conventional manufacturing methods. It is widely used in various industries, including aerospace, automotive, architecture, healthcare, and consumer goods.