How CAD Technology benefits from Dynamic Modeling

Alexander Pope, in the 17th century, coined the phrase “A little knowledge is a dangerous thing”. This phrase holds true in many cases, because a small amount of knowledge could lead to overconfidence. An overconfident person is likely to make decisions hastily without taking all facts into account.

What does this phrase have to do with Computer Aided Design? A CAD engineer who is trained primarily to use CAD software tools, but who lacks sound theoretical training, fits this phrase in many respects. Such a CAD engineer who has successfully solved many routine design problems with CAD tools could become overconfident in his/her design skills.The time will come when this overconfident engineer, who lacks adequate theoretical training, models a non-routine problem incorrectly and misinterprets the results. Consequently, an incorrect design for a product is implemented. Unless the design error is caught and fixed, the launched product will be an accident waiting to happen. Failure of a poorly-designed product could cost a company a lot of time, money, and loss of reputation.

Many CAD and engineering organizations are aware of such dangers, and they include Dynamic Modeling into their product design cycles. Doing so provides “checks and balances” before a design materializes into a product.

This article examines the roles that Dynamic Modeling plays in CAD-driven product design.

Specifically, the article tries to answer these questions:

- What is Dynamic Modeling, and is it needed for all product designs?

- Are all CAD engineers qualified to perform CAD enabled dynamic modeling?

- What are the benefits of Dynamic Modeling?

- How is Dynamic Modeling being used?

What Is Dynamic Modeling and Is It Needed for all Product Designs?

Dynamic modeling simulates the behavior of an object over time. In engineering, dynamic models are described in terms of causal loops or feedback and control systems.

The causal loop captures the structural makeup or components that comprise a complex system or product, and the interactions between them. Computer models are built to simulate how the system responds to time-varying states and external loads, and how the system responds over time.

Dynamic modeling is not restricted to time-variant behavior of physical structures, but it is also used for artificial intelligence, economics, psychology, political science, and many other disciplines.

Not all products require dynamic modeling. For example, stationary objects such as statues are not subjected often to time varying externals loads such as wind forces or earthquakes. Therefore, static models suffice for determining their structural integrity.

Examples of good candidates for dynamic modeling are:

- Bridges, which experience variable loadings, wind forces, and perhaps earthquakes.

- Offshore oil production platforms, which are subjected to ocean waves, wind, and current loadings.

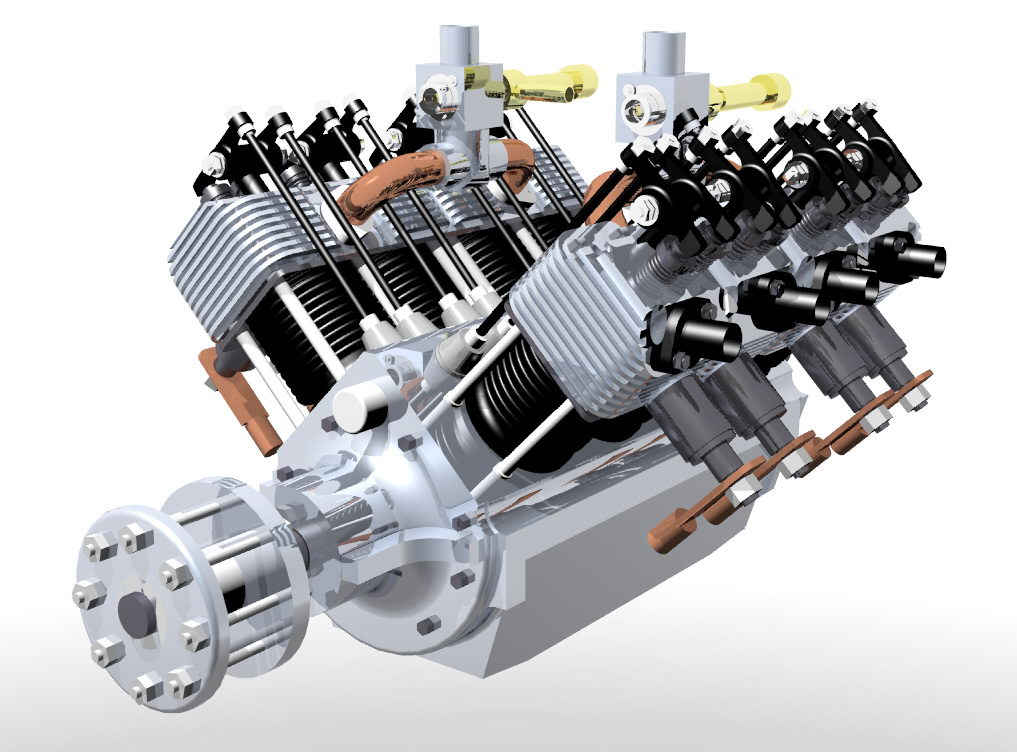

- Automobiles, which are subjected to shock loadings and aerodynamic forces.

- Buildings and structures in earthquake-prone areas, because they endure seismic loadings.

Are all CAD Engineers Qualified to Perform CAD Enabled Modeling?

Not all CAD engineers have the skills to perform dynamic modeling adequately. CAD software tools which provide its capabilities will incorporate them as FEA, CFD, and other software packages. The CAD engineer who has not taken advanced courses in Solid Mechanics, Fluid Mechanics, Feedback and Control Systems, Vibration Analysis, Random Mechanics, and similar courses may lack sufficient theoretical skills to adequately model and interpret non-routine design problems with CAD software.

Dynamic modeling which is performed incorrectly could produce design errors with disastrous consequences, if the errors:

- Are not detected and corrected by peers,

- Are not detected during design reviews,

- Are not detected during the prototyping and testing phase.

Once a poorly designed product is launched, the consequences could mean applying fixes in the field, having a product recall, or withdrawing a product. None of these options is desirable, because it creates customer dissatisfaction, possible lawsuits, loss of income, and loss of reputation.

What are the Benefits of Dynamic Modeling?

If properly performed, Dynamic Modeling can reveal design flaws that may not show up readily during the prototyping and testing phases of the product design cycle.

Unique benefits that dynamic modeling provides include:

- Identifying interactions between subsystems of a complex product which may be too expensive to create during physical prototyping and testing,

- Identifying potential failure modes which should be tested in physical prototypes, before hard tooling,

- Simulating dynamic loadings which may be difficult to create during actual testing,

- Identifying functional limitations on the use of a product.

Although some complex systems may be difficult to model accurately, it provides extra product performance data from virtual prototypes. Testing and validation of data obtained from virtual prototypes within physical prototypes should create a robust and reliable design.

How is Dynamic Modeling being used?

A few examples should clarify the benefits that Dynamic Modeling brings to CAD design work.

- Engineers at NIST (National Institute of Standards and Technology) are building a horizontal smokestack computer model called the Scale-Model Smokestack Simulator. The Dynamic Model will predict the amount of carbon dioxide coming out of smokestacks with 1% accuracy, compared with current measurement accuracy of 10 to 20%. This Dynamic Model will make it easier to address the problem of CO2 emissions which the EPA is concerned about.

- The University of Le Havre uses Dynamic Modeling to efficiently calculate optimized mold measurements for a ship hull.

- SolidWorks provides modeling software within their CAD offerings for all types of industrial robot movements. The software also translates code from one robot to another, and can import models from major CAD systems.

- It is being used extensively to study the impact of Self Driving vehicles on traffic flow.

Conclusions

When it is used effectively and correctly, creates virtual product prototypes that can identify failure modes and functional limitations of a design at an early stage.

When dynamic modeling is used together with Additive Manufacturing (or 3D printing) for physical product prototyping, the design cycle could be significantly shortened. Consequently, reliable and cost effective products will be launched, and the cost saving will benefit both the product manufacturer and the consumer.

Australian Design & Drafting Services provide excellent service for CAD Design and Drafting. Contact Us for more info