reverse-engineering-of-automotive-components

Innovation is our strength

CASE STUDY – Mechanical Engineering Design and Drafting Services

REVERSE ENGINEERING OF AUTOMOTIVE COMPONENTS

Engineering Design & Drafting | CAE Services: CFD & FEA | Reverse Engineering | Rapid Prototyping | Product Design | Value Engineering | PLM Services | Technical Documentation

Case Study Highlights

REVERSE ENGINEERING OF AUTOMOTIVE COMPONENTS

Client Profile:

- Automotive Components Parts Manufacturer, Australia

The Objective:

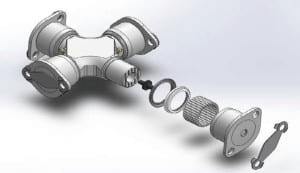

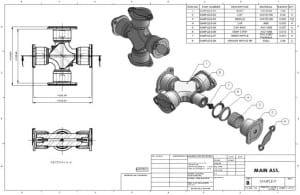

- To reverse engineer U-joint, brake drum and brake rotors developed for Automotive Components applications and obtain comprehensive design information for manufacturing purposes

The Challenges:

- Calculating dimensions of entire assembly as well as individual assembled components

- Utilizing 3D scanning as well as CMM techniques to capture the profile and generate CAD model

- Recording dimensions manually for critical and/or complex regions for accurate geometry building

- Performing design changes as per the requirements

Solution:

- The dimensions of universal joint, brake drum and brake rotor were calculated using 3D scanning, CMM technique as well as manual measurement methods. For reverse engineering requirements, the parts were disassembled and individual component dimensions were measured. Based on the details captured, a CAD model was developed to digitally document the design information. Further design changes were performed as per client’s requirements and final assembly with detailed manufacturing drawings was prepared.

Reverse engineering is increasingly becoming a useful tool for manufacturers to re-consider their product design in an efficient and cost-effective manner. Providing insights about the design parameters affecting the performance and longevity of the product, reverse engineering also serves as a method to study competitor products and keep pace with the market requirements.

One of the prominent aftermarket auto parts manufacturers in Australia needed reverse engineering solution for a broad inventory of their products. Australian Design and Drafting Services offered a qualitative solution for three major automotive parts using a team of qualified CAD professional and design engineers.

Solution:

- Based on the receipt of parts from the client, a digital design process was initiated. Dimensions were calculated manually as well as using 3D scanning and CMM methods. For reverse engineering universal joint, brake drum and disc brake rotor, entire assembly was disassembled and individual component dimensions were recorded with detailed information on material, fits and tolerances.

- The information obtained was utilized to develop CAD drawings for inspection purposes and identify design improvements in critical regions leading to early failures. Based on the inputs received from the client, the designs of the parts were altered, and final assembly drawings were developed. Detailed manufacturing drawings were also developed to meet the shop floor requirements.

Benefits:

- Digital design information provided room for quick design changes

- Reverse engineering helped identify regions needing design alterations

- Manufacturing drawings significantly reduced the product development process

About Australian Design And Drafting Services

Australian Design and Drafting Services is a specialist firm providing engineering solutions to organizations across the globe. We have extensive experience in providing concept to manufacturing and post-manufacturing solutions to clients with a team of expert design engineers, CAD professionals and simulation analysts. We are based in Australia, serving 24×6, with a world-class infrastructure, hardware and software capabilities to address complex engineering problems with the least turnaround time.