CONCEPT TO MANUFACTURING SUPPORT FOR PROCESS YARNS AND FABRIC REINFORCEMENT MANUFACTURER

Innovation is our strength

CASE STUDY – Mechanical Engineering Design and Drafting Services

CONCEPT TO MANUFACTURING SUPPORT FOR PROCESS YARNS AND FABRIC REINFORCEMENT MANUFACTURER

Engineering Design & Drafting | CAE Services: CFD & FEA | Reverse Engineering | Rapid Prototyping | Product Design | Value Engineering | PLM Services | Technical Documentation

Case Study Highlights

CONCEPT TO MANUFACTURING SUPPORT FOR PROCESS YARNS AND FABRIC REINFORCEMENT MANUFACTURER

The Client:

- Industry : Process yarns and fabric Manufacturer

- Location : Germany

The Objective:

- To conceptualize, model and implement the plant layout for manufacturing process yarns and fabric reinforcement for rubber industry.

The Challenges:

- Understanding the manufacturing requirements and identify the requirements of resources for plant

- Conceptualizing the plant layout as per the actual available site space, production capacity required and cost constraints

- Identifying constraints related to the implementation of conceptualized layout

- Developing actual prototype machines as per the design calculations

Solution:

The overall project was accomplished by a team of 5 engineers and draftsmen in six stages. The manufacturing requirements and plant resources were identified, based on which the conceptual model was developed. The plant layout with general arrangement of equipment was finalized collaborating with the client. The structure design was also analyzed through simulation tools before actual implementation. Through the use of CAD tools, equipment prototypes were developed and manufactured simultaneously. Extensive support was provided for manufacturing support as well as erecting the plant successfully.

Software Used: AutoCAD

As an engineering solutions provider to organizations globally, a leading process yarn and fabric manufacturer from Germany approached us for a comprehensive concept to manufacturing solution, in order to setup the manufacturing plant for production. ASTCAD’s team of engineers and draftsmen collaborated with the client to conceptualize the layout, considering the available resources, costs, site space and production capacity required.

Solution:

The overall project was separated into six stages:

- Concept development

- General arrangement drawing preparation

- Analysis and validation

- Prototype manufacturing

- Development of manufacturing drawings

- Manufacturing support & support in plant erection

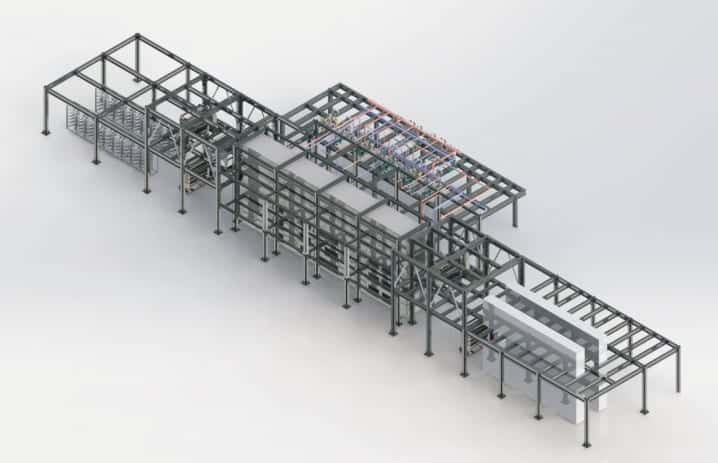

Based on the project specifications, the concept was first idealized with sketches and preliminary design calculations to identify general arrangement layout. Through CAD tools, the layout was modeled and finalized after several modifications. A 3D layout was also prepared for better understanding and visualizing the arrangement of equipments. The structure modeled was also analyzed using simulation tools to identify the effects of actual loading conditions and design modifications required.

For prototype manufacturing of equipments, detailed shop floor drawings were prepared and actual prototypes were developed followed by an onsite quality check. ASTCAD also assisted in developing manufacturing drawings and supported the plant erection team to implement the finalized CAD model into actual layout.

Benefits:

- The entire plant data was documented with adequate sketches, general arrangement drawings and detailed shop floor drawings.

- Established the plant layout ready to begin manufacturing with no lag in production time

- Support in plant erection reduced implementation time and associated cost

- CAD documentation provided a database to the client in implementing similar plant at different locations

About Australian Design And Drafting Services

Australian Design and Drafting Services is a specialist firm providing engineering solutions to organizations across the globe. We have extensive experience in providing concept to manufacturing and post-manufacturing solutions to clients with a team of expert design engineers, CAD professionals and simulation analysts. We are based in Australia, serving 24×6, with a world-class infrastructure, hardware and software capabilities to address complex engineering problems with least turn around time.