CFD helps to predict the flow behaviour inside building HVAC application

Innovation is our strength

CASE STUDY – CFD helps to predict the flow behaviour inside building HVAC application

Engineering Design & Drafting | CAE Services: CFD & FEA | Reverse Engineering | Rapid Prototyping | Product Design | Value Engineering | PLM Services | Technical Documentation

Case Study Highlights

The Client:

- Industry: BIM

- Location: Australia

The Objective:

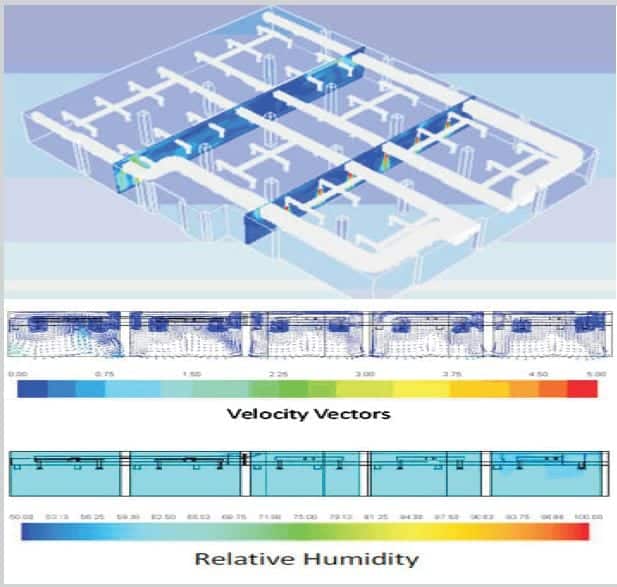

- Gauge the simulation of the prevailing HVAC system to check velocity, humidity and hot pockets

The Challenges:

- HVAC system designer must give confidence to architects, building designer and owner that the ventilation system will perform as required.

- Based on the building design and requirements, airflow and temperature should be mention at the human comfort level

- It is important to optimize the HVAC system the requirement by maintaining human comfort

Solution:

- Determined the velocity, temperature and relative humidity (RH) profile inside building domain using CFD simulation With the help of effective computational fluid dynamics analysis; it is possible to expedite well-organized and swift simulation of heat transfer. Fluid flow analysis within the component, structure or a product helps to regulate the performance level across different fluid forces.

- When CFD is assimilated with state-of-the-art CAD technology it eases out intricacy and stresses from fluid flow analysis process, which can be cohesively utilized as a consistent feature in the iterative design process.

- With the ever-increasing importance levied on ground-breaking engineering, designing, and manufacturing processes; it is becoming vital to comprehend thermal and fluid dynamics of innovation and unified solutions for fundamental problem areas.

- A leading BIM company specialized in building design, engineering and installation of HVAC systems needed to assess the flow behaviour inside building HVAC application. The company is regarded as one of the best in full-service engineering. Their clients, peers, and prospects know the RMF name and depend on them to see their projects through from concept to completion.

- Today, their talented staff of full-service engineers smears grander planning, design, engineering, and commissioning services to resolve engineering challenges, large and small, for clients across Australia. The company consisted of an elite team of full-service engineers skilled in applying grander planning, design, engineering, and commissioning services to crack challenges for clients nationwide.

- Their swift receptiveness, industry-leading tech-savvy, and dedicated project teams make up the RMF difference. The client wanted to gauge the simulation of the prevailing HVAC system to check velocity, humidity and hot pockets inside the building HVAC application. It is very important to note that the HVAC application is very important for successful operation inside the building.

- According to the local weather conditions, it is critical that the building design and requirements, airflow and temperature are maintained at the human comfort level. For that to be done it is important to be able to optimize the HVAC system for constantly changing requirements based on the capacity of the building.

- It is also very important to make sure that the HVAC system designer gives confidence to architects, building designer and owner regarding the ventilation system to be performed as per the requirement.

Technology / Software Used:

After understanding the requirement of the client, we decided to use ANSYS Fluent for the successful execution of the project.

The Solution:

ASTCAD utilized ANSYS Design Modeler tool to create a 3D CAD model of building and HVAC duct system. With the help of ANSYS Fluent, the company was able to simulate and analyze human comfort inside the building. The company also determined the velocity, temperature, and relative humidity (RH) profile inside the building domain using CFD simulation. ANSYS Fluent was also useful in getting the flow simulation done after implementation of heat fluxes and supply/return air information. This solution can also be provided using OpenFOAM, STAR CCM+, Abaqus CFD, COMSOL Multiphysics.

Benefits CFD HVAC Application :

- With the help of CFD simulation, the HVAC industry can perform testing and study design changes in the virtual environment.

- It also ensured the client that the installation of the HVAC system would enable them to mention temperature and RH at the human comfort level.

- CFD analysis helped in analyzing the design correction to make sure those requirements before the installation of the HVAC system for value addition to the work.

- Utilizing CFD analysis client can classify the hot pockets inside the building, which might cause discomfort to the residents.

About Australian Design and Drafting Services

Australian Design and Drafting Services is a specialist firm providing engineering solutions to organizations across the globe. We have extensive experience in providing concept to manufacturing and post-manufacturing solutions to clients with a team of expert design engineers, CAD professionals and simulation analysts. We are based in Australia, serving 24×6, with world-class infrastructure, hardware and software capabilities to address complex engineering problems with least turn around time.