reverse engineering design optimization of steel strapping machine

Innovation is our strength

Reverse Engineering Pneumatic Steel Strapping Machine

Engineering Design & Drafting | CAE Services: CFD & FEA | Reverse Engineering | Rapid Prototyping | Product Design | Value Engineering | PLM Services | Technical Documentation

Case Study Highlights

Client Profile:

- Tools Manufacturer, Australia

Objective:

- To reverse engineer steel strapping machine for design optimization and document design information digitally

Challenges:

- 3D scanning complex machine geometry to capture accurate geometrical dimensions

- Performing manual dimension measurements to obtain missed-out geometrical information during the 3D scanning process

- Developing CAD models, 3D and 2D detailed drawings for manufacturing purposes

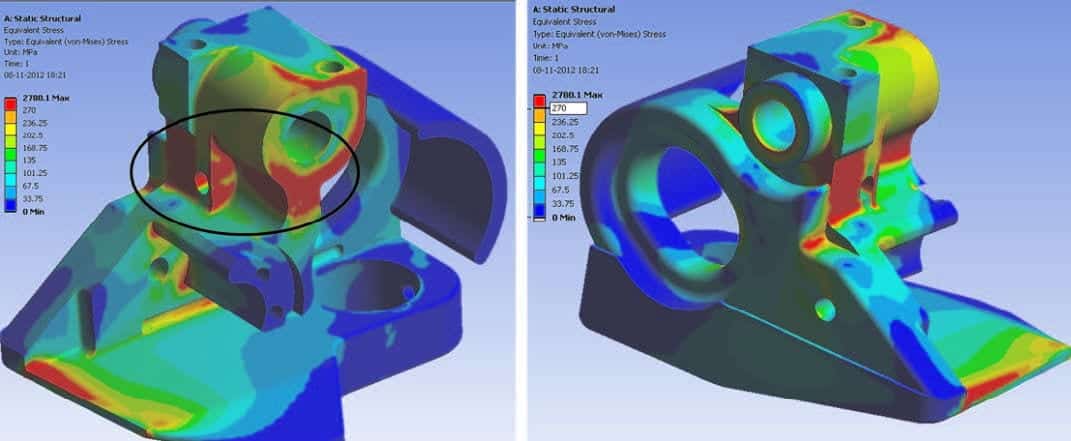

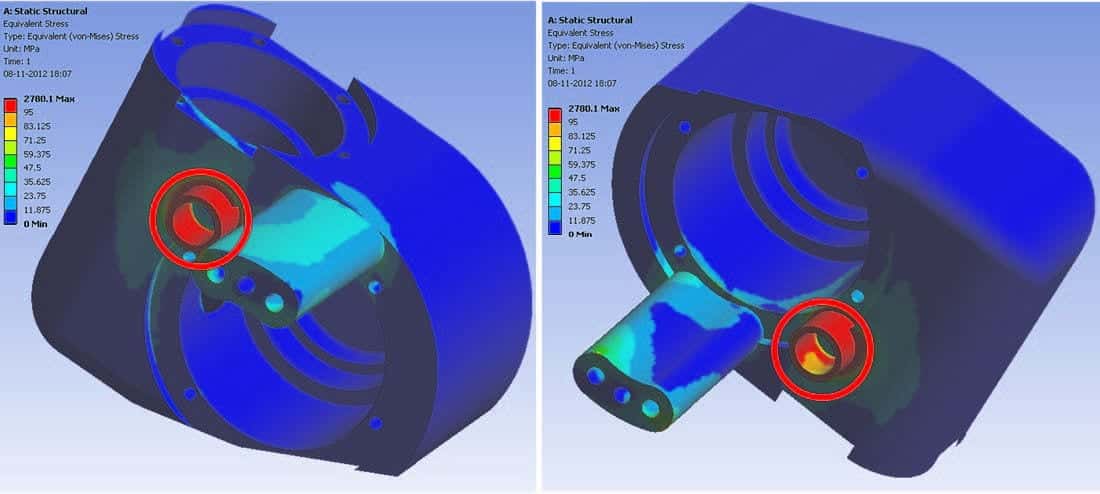

- Evaluating the design for stress concentration and performing subsequent optimization to propose better design optimization of the strapping machine

Solution:

- The CAD model of the steel strapping machine was developed using 3D scanning technique and manual dimension measurement. In order to reverse engineer, the machine was disassembled sequentially to capture accurate geometric information of each individual component. The final design obtained was utilized to perform structural analysis for the identification of stress concentration.

- Based on the analysis results, the design was optimized to withstand high-stress values without failure.

Reverse engineering is essentially an important method to identify flaws in the existing design of the product and improve the design subsequently, without major investment in cost and time. It is crucial to figure out the potential design errors in the product leading to premature failure.

Apart from competitive benefits, the reverse engineering process imparts manufacturers with comprehensive design information of their product, from which further innovation can be accomplished

A leading tools manufacturer from the Melbourne, Australia approached ASTCAD to reverse engineer steel strapping machine, which possessed a design flaw that led to premature failure. The client needed to investigate the problem through simulation and needed a design solution to overcome the early failure issue.

Solution:

- The steel strapping machine prototype was transformed into digital CAD model using a 3D scanning technique and manual measurements. To reverse engineer the machine, individual components were disassembled and respective geometrical information was recorded to obtain the accurate overall design of the machine. Individual component drawings, as well as detailed manufacturing drawings, were prepared. The components were then analyzed separately for structural integrity and stress concentration to identify critical areas in design requiring optimization.

Based on the analysis results obtained, it was observed that two of the machine components needed modification in design in order to sustain stress levels resulting during the machine operation. Modifications in the design were made and the new design of the machine was proposed with better ergonomics and strength against loads to withstand premature failure.

Benefits:

- Competitive advantage in the market with improved product design 30% reduction in prototyping test trials

- Identified major design flaws with the reduced turn around and faster time to market

- Digital design documentation for future modification in design

About Australian Design and Drafting Services

Australian Design and Drafting Services is a specialist firm providing engineering solutions to organizations across Australia. We have extensive experience in providing concept to manufacturing and post-manufacturing solutions to clients with a team of expert design engineers, CAD professionals and simulation analysts.