DESIGN SOLUTION FOR BUNDED FUEL TANKS OF DIFFERENT CAPACITIES & REGULATORY STANDARDS

Innovation is our strength

CASE STUDY – DESIGN SOLUTION FOR BUNDED FUEL TANKS OF DIFFERENT CAPACITIES & REGULATORY STANDARDS

Engineering Design & Drafting | CAE Services: CFD & FEA | Reverse Engineering | Rapid Prototyping | Product Design | Value Engineering | PLM Services | Technical Documentation

Case Study Highlights

DESIGN SOLUTION FOR BUNDED FUEL TANKS OF DIFFERENT CAPACITIES & REGULATORY STANDARDS

Client Profile:

Fuel & Water Tanks Manufacturer

Objective:

To offer a design solution through CAD tools for bunded fuel tanks of different capacities and global standards

Challenges:

- Identifying global above-ground fuel storage regulations

- Determining the required wall thickness to sustain fuel pressure

- Developing detailed manufacturing drawings and 3D layouts

- Providing on-site support for manufacturing requirements

Solution:

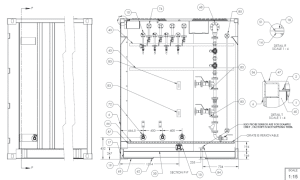

The bunded container for fuel storage with different capacities was developed with a team of design engineers and CAD professionals, maintaining the required regulatory standards such as UN, ADR, PPG2, BS799, UL, etc. Detailed manufacturing drawings were prepared along with on-site support to the manufacturing team.

Software Used:

A major bunded container manufacturer with a global presence approached ASTCAD for design solution and manufacturing support for their different range of storage tanks.

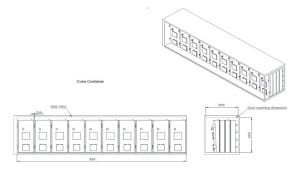

Bunding is a secondary containment system required to store chemicals and fuels to protect the environment from leakage and spills. Bunded containers are legally required in most countries to avoid spillage and hazardous impact on the environment.

Their design specifications depend upon the capacity and regulatory standards developed specifically for different countries.

Solution:

The design of bunded containers for fuel storage was developed using professional CAD tools by a team of design engineers and CAD specialists.

Considering the regulatory norms of Australia, customized tank designs were developed with detailed manufacturing drawings to assist manufacturing team comprehensively.

Initial assistance included a design solution for a bunded container 20/40 feet above ground level with different variance and regulatory standards. At present, ASTCAD extends design solution for tanks with capacity ranging from 100 to 16000 Gallons.

Benefits:

- The comprehensive design solution for bunded tanks of different capacity reduced time to market

- Detailed manufacturing drawings assisted in reducing the manufacturing time frame

- Easier design modification for future requirements

About Australian Design And Drafting Services

Australian Design and Drafting Services is a specialist firm providing engineering solutions to organizations across the AUSTRALIA. We have extensive experience in providing concept to manufacturing and post-manufacturing solutions to clients with a team of expert design engineers, CAD professionals and simulation analysts. We are based in Australia, with world-class infrastructure, hardware and software capabilities to address complex engineering problems with least turn around time.