Choosing Between 2D and 3D CAD Applications

It’s an argument covering 2D vs. 3D CAD applications that rages with developers and designers. It works on both sides, touting the merits and preferences with opposing CAD choices’ flaws. There would be a time when the argument seems academic to operations. Also, the project managers would have minimal exposure to its actual CAD interface. This article provides a clear perspective of the debate.

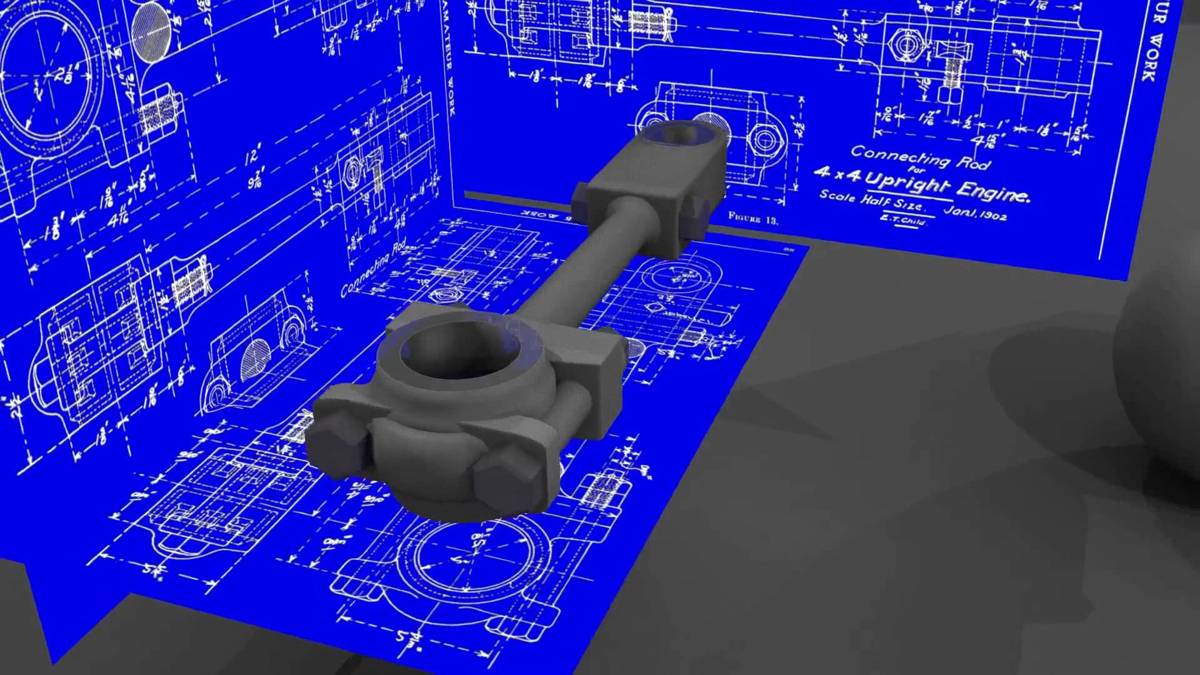

To begin with, the main difference between 2D and 3D applications should instead be self-explanatory. The 2D works solely on a single plane, while 3D allows the construction to realize three-dimensional surfaces fully. It is essential to note that 3D CAD makes proper usage of all image building techniques available within most 2D CAD applications.

It should allow users to open the third dimension and construct solid objects. It might seem that the signal at the end of the debate from the outset adds, why to argue that 2D CAD is superior in any setting if 3D CAD offers symmetrical capabilities. Therefore, the two other factors to consider when choosing 2D and 3D CAD software are required.

The first thing to note here is the price for how businesses prefer 3D CAD over 2D CAD drafting software. 3D CAD applications can inarguably be more expensive than older 2D software. It can sometimes tune to thousand dollars also. If you want to manage a small business or sole proprietorship, all you need is 2D CAD functionality. It’s a software upgrade with making the wisest choice.

Secondly, 3D CAD applications are far more complex. The users overcome a much steeper learning curve. Since it moves an object from a 2D environment into a 3D environment, it can increase the surface areas adding detail exponentially. Along with this, the control systems in 3D CAD applications are more difficult to master.

If you run a small shop with less than four CAD users, you need to consider the immediate decrease in capability where the shop experiences the software changeover from 2D to 3D. It staggers 3D implementation by adding the best choice. It allows half of the design force with upgrade while keeping others working on 2D applications. It should give an overall output nominal. As soon as your designers have acclimated to a 3D workspace, one can continue upgrading in segments.

In short, there’s no actual argument here. The 3D CAD applications are way superior in any design situation. However, implementation can cost more and would be time-consuming. Managers should be aware of this and plan CAD software upgrades accordingly.

Choosing between 2D and 3D CAD applications depends on your specific needs and the nature of your projects. Both 2D and 3D CAD software have their advantages and are suitable for different purposes. Here’s a breakdown of their characteristics to help you decide:

2D CAD Applications:

- Simplicity: 2D CAD software is generally easier to learn and use, making it a good choice for beginners or for simple drafting tasks.

- Drafting and Schematics: If your primary focus is on creating technical drawings, schematics, floor plans, or electrical diagrams, 2D CAD is often sufficient.

- Faster Production: 2D drawings can be quicker to produce, making them a better choice for projects where speed is crucial.

- Less Resource-Intensive: 2D CAD software typically requires fewer system resources, making it suitable for older hardware or less powerful computers.

- Cost-Effective: Many 2D CAD applications are more affordable than their 3D counterparts.

3D CAD Applications:

- Design Visualization: If you need to create realistic models, visualize designs in 3D, or simulate real-world scenarios, 3D CAD is essential.

- Prototyping and Testing: 3D models allow for virtual prototyping and testing before physical production, which can save time and resources.

- Complex Geometry: For intricate designs or products with complex shapes, 3D modeling provides greater accuracy and detail.

- Interdisciplinary Collaboration: 3D models are more comprehensive and can facilitate better communication and collaboration among various teams, such as design, engineering, and manufacturing.

- Animation and Rendering: If you want to create animations or high-quality renderings for presentations or marketing purposes, 3D CAD is necessary.

Considerations for Your Decision:

- Project Requirements: Assess the specific needs of your projects. Are you creating simple drawings, or do you need intricate 3D models?

- Learning Curve: Consider your skill level and the time you can invest in learning the software. 2D CAD is generally simpler to pick up.

- Collaboration: If you’re working with others, determine whether 2D or 3D models are more suitable for effective communication and collaboration.

- Future Growth: Consider whether your projects might evolve to require 3D capabilities in the future. Investing in 3D CAD now could save you from switching software later.

- Budget: Evaluate the cost of the software, including any ongoing licensing fees or subscriptions.

- Hardware: Check the system requirements of the software to ensure your computer can handle it.

If you’re looking for any help regarding design and drafting services, well, we are here. Please don’t hesitate to contact us at Australian Design and Drafting Services or call us at 1800 287 223 (Toll-Free).

What are the advantages of 3D over 2D CAD drafting?

Using 3D CAD drafting offers several advantages over traditional 2D drafting:

Visualization: 3D CAD allows you to create realistic visualizations of your designs, which helps in better understanding and communication of the design intent.

Error Detection: With 3D CAD, you can detect errors and interferences more easily compared to 2D drafting. This helps in reducing design flaws and streamlining the design process.

Improved Design Communication: 3D models provide a clearer representation of the final product, making it easier to communicate design ideas to stakeholders, clients, and team members.

Virtual Prototyping: 3D CAD enables the creation of virtual prototypes, which can be used for testing and simulation before physical prototypes are built. This helps in identifying and rectifying issues early in the design process, reducing time and cost.

Design Iterations: Iterating on designs is faster and more efficient in 3D CAD compared to 2D drafting. Modifications can be made to the 3D model with ease, allowing for rapid prototyping and experimentation.

Documentation: 3D CAD software often includes tools for automatically generating detailed drawings, bills of materials, and other documentation, which can save time and reduce errors compared to manually creating these documents in 2D.

Integration with Other Software: 3D CAD models can be easily integrated with other software tools such as analysis software, CAM (Computer-Aided Manufacturing) software, and simulation software, allowing for a more comprehensive design and manufacturing process.

Cost Savings: While the initial investment in 3D CAD software and training may be higher compared to 2D drafting, the long-term cost savings can be significant due to reduced errors, faster design iterations, and improved efficiency.

What is the difference between CAD and 3D CAD?

Computer-Aided Design (CAD) is a broad term that refers to the use of computer technology to assist in the creation, modification, analysis, or optimization of a design. CAD software allows engineers, architects, and designers to create precise drawings and models of objects, buildings, or systems in a digital environment.

3D CAD, on the other hand, specifically focuses on creating three-dimensional models of objects or structures. While traditional CAD software may include 2D drafting capabilities, 3D CAD software primarily revolves around creating and manipulating 3D models. These models can be viewed from any angle, rotated, scaled, and even simulated to assess factors like structural integrity, performance, or aesthetics.

In summary, while CAD encompasses a broader range of design tools and techniques, 3D CAD specifically deals with the creation and manipulation of three-dimensional models.